Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Chemical Name

- Pigment Type

- Plastics & Elastomers Functions

- Technologies

Features & Benefits

Applications & Uses

- Suggestions for Use

Ti-Pure™ R-960 is designed primarily for exterior color durable applications. The surface treatment of Ti-Pure™ R-960 minimizes potential reaction with polymer resins and additives, while continuing to provide the high level of UV radiation protection associated with rutile titanium dioxide. In tinted exterior applications, the lower opacity strength of Ti-Pure™ R-960 actually minimizes the total colorant cost at the desired level of UV protection. Rutile titanium dioxide is an efficient UV radiation protector for plastic applications because it strongly absorbs radiation below 380 nm. Rutile titanium dioxide, in the presence of water and oxygen, may then act as a photocatalytic agent. Ti-Pure™ R-960 is surface coated with silica to minimize this photocatalytic potential. An additional alumina treatment improves dry bulk conveying and dispersibility.

Optical Properties

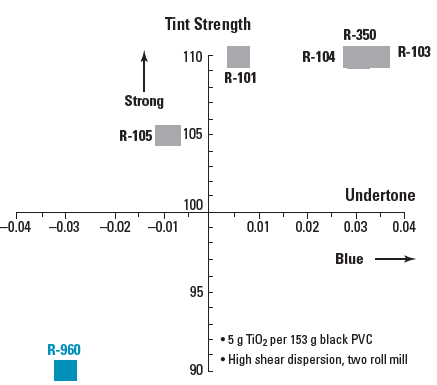

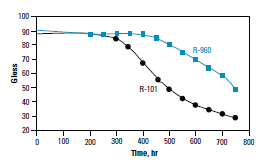

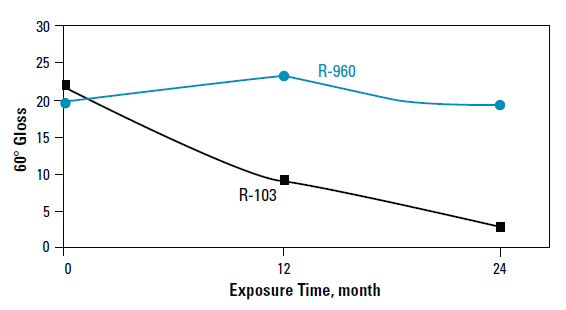

Ti-Pure™ R-960 provides maximum surface retention while still providing efficient UV radiation protection. Below Figures demonstrate the improved gloss retention of R-960 in plastics, compared to grades Ti-Pure™ R-101 and Ti-Pure™ R-103.

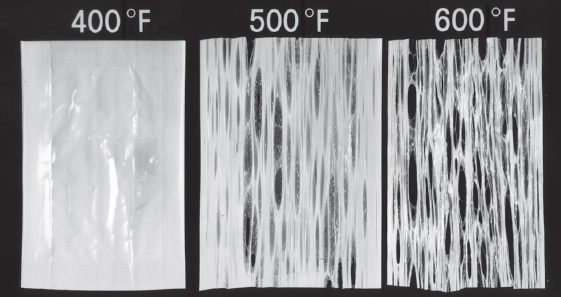

The surface treatments used to optimize Ti-Pure™ R-960 outdoor performance are hygroscopic. Moisture absorbed during shipping and storage can affect film integrity at very high TiO2 loadings and temperatures. As Figure shows, Ti-Pure™ R-960 must be evaluated carefully for film applications. For applications requiring less moisture, Ti-Pure™ R-105 is recommended.

Gloss Retention of Polypropylene, Xenon Exposure

Gloss Retention of PVC, Florida Exposure 45° South

Lacing Resistance versus Temperature, Ti-Pure™ R-960

Properties

- Color

- Physical Form

- Physical Properties

- General Properties

Opacity Strength Low Undertone Tint Cream Dispersibility in (Plasticized Vinyl) Good Dispersibility in (Plasticizers) Good Dispersibility in (Dry Blending Operations) Good Dispersibility in (Melt Compounding) Good Chalking Resistance Excellent

| Value | Units | Test Method / Conditions | |

| TiO₂ Content | min. 89 | wt% | — |

| Alumina Content | max. 3.5 | wt% | — |

| Amorphous Silica Content | max. 6.5 | wt% | — |

| Organic Treatment | None | — | — |

| Specific Gravity | 3.9 | — | — |

| pH Value | 7.4 | — | — |

| Resistance (Aqueous Slurry) | min. 4 | k ohm-cm | — |

Packaging & Availability

- Packaging Type

- Regional Availability

- Packaging Information

Ti-Pure™ R-960 rutile titanium dioxide is available in a range of packaging to meet your needs:

- 25 kg multi-ply paper bags

- 1 metric ton (1,000 kg) flexible intermediate bulk containers