Knowde Enhanced TDS

Identification & Functionality

- Chemical Name

- Agrochemical Functions

- CAS No.

- 9038-95-3

- EC No.

- 618-542-7

- Technologies

- Product Families

- Chemical Group

Block Copolymer

Features & Benefits

- Functions

- Emulsifier, Adjuvant, Wetting Agents

- Product Features

- Can be used as a wetting agent

- 100% nonionic surfactant used as emulsifier in a variety of agricultural formulations

- EPA 40 CFR 180.940a, 180.940c and 180.960 approved

Applications & Uses

- Markets

- Applications

TOXIMUL 8325 is 100% active nonionic surfactant that can be used as an emulsifier, wetting agent, or dispersant in a variety of agricultural formulations.

- Capsule Suspensions (CS)

- Emulsifiable Concentrates (EC)

- Microemulsions (ME)

- Oil Dispersants (OD)

- Oil in Water Emulsions (EW)

- Suspension Concentrates (SC)

- Suspoemulsions (SE)

- Tank Mix Adjuvants

Properties

- Formulation Type

- Physical Form

- Appearance

- Hazy clear to pale yellow liquid

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Actives Content | 100 | % | — |

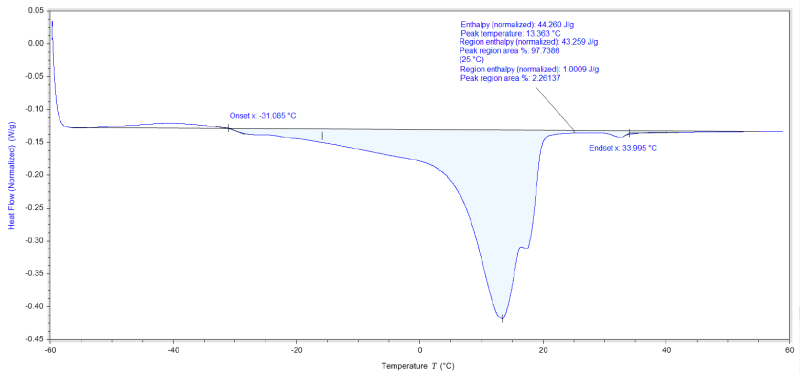

| Melt Range | -31.09 to 34.0 | ºC | — |

| Cloud Point | 20 | °C | — |

| Melted Quantity (at 25ºC) | 97.74 | % | — |

| Density (at 25°C) | 1.05 | g/ml | — |

| Hydrophobe | Butanol | — | — |

| Flash Point | min. 94 | °C | — |

| Base | Butyl | — | — |

| HLB | 14.1 | — | — |

| Pour Point | 26 | °C | — |

| Average Molecular Weight | 4000 | — | — |

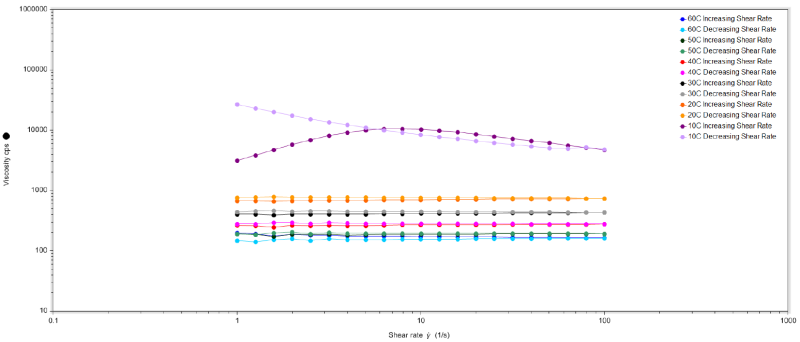

| Viscosity (at 25°C) | 620 | cPs | — |

| Surface Tension (0.1% Aqueous) | 38.2 | dynes/cm | — |

| Moisture Content | 0.1 | % | — |

| pH Value (5%, aqueous) | 6.0 | — | — |

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- Melt Point Determination of TOXIMUL® 8325

- Rheology of TOXIMUL® 8325

Packaging & Availability

- Packaging Type

- Packaging

TOXIMUL 8325 is available in drum, tote, or bulk quantities.

Storage & Handling

- Storage Conditions

Non-Bulk Storage Recommendations: TOXIMUL 8325 should be stored in closed containers and kept in a cool, dry place away from incompatible materials (see Section 10 of the SDS). Product temperatures over 130°F (54°C) are not recommended. If material is frozen it should be heated gently and stirred to ensure it is homogeneous prior to use. Drums should be vented prior to heating to avoid excessive pressure build up.

Bulk Storage Recommendations: TOXIMUL 8325 should be stored in vessels of 316 stainless steel and glass fiber-reinforced polyester. Oven-cured phenolic and epoxy/phenolic linings may also be used. Material should be stored between 80 - 100°F. An internal hairpin coil of 316 stainless steel with low pressure steam (under 50 psig) should be used if heating is required.

- Workplace Exposure

Occupational exposure can occur primarily through skin contact or via inhalation of vapors and mists. Engineering controls, personal protective equipment, and other workplace safety practices should be used to control these exposures.

- Handling Precautions

- Normal safety precautions (e.g., gloves and safety goggles) should be employed when handling TOXIMUL 8325.

- Contact with the eyes and prolonged contact with the skin should be avoided.

- Wash thoroughly after using the material.