Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Core Type

- Polymer Name

- Composite Materials Functions

- Technologies

- Product Families

Features & Benefits

- Materials Features

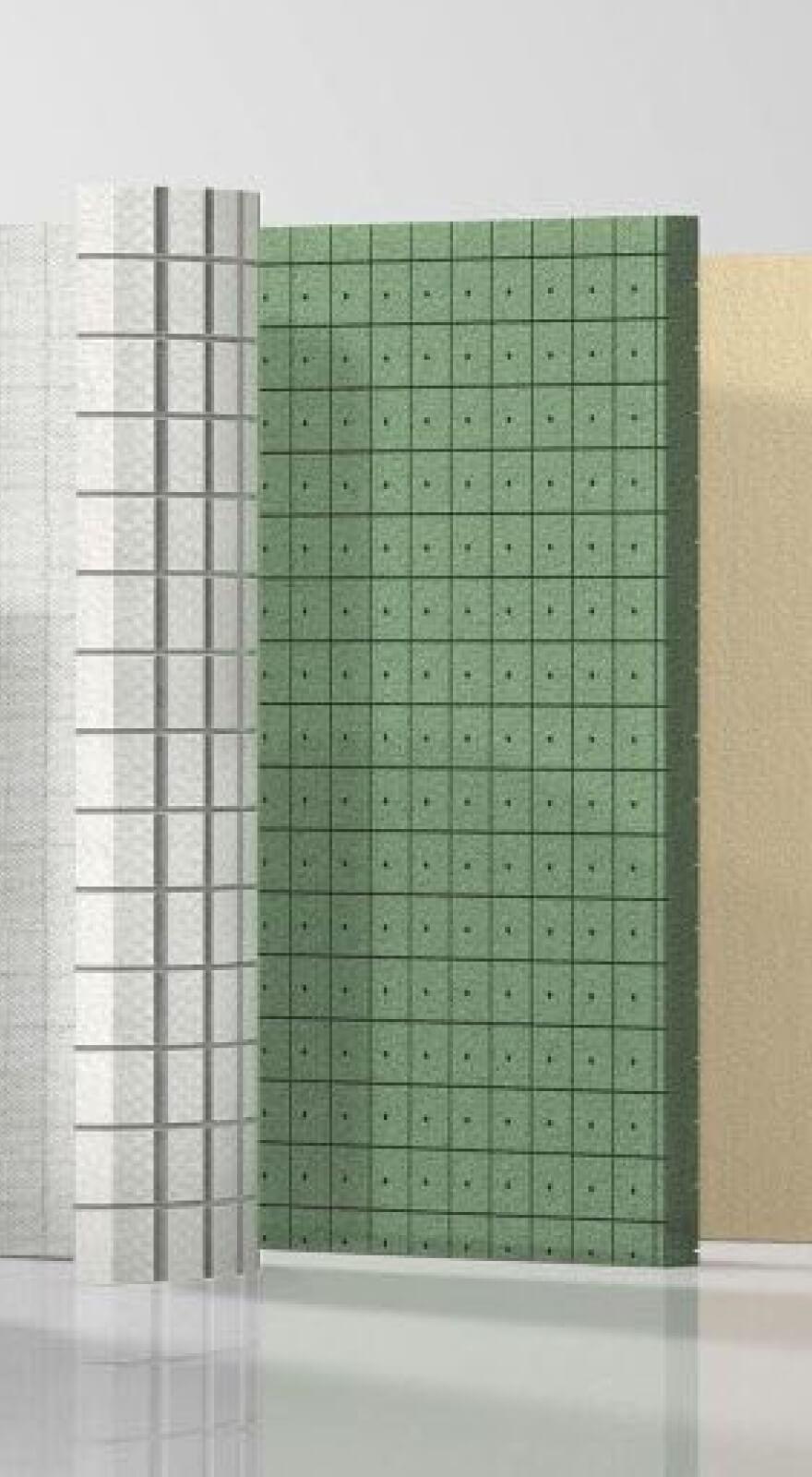

- Product Highlights

- Outstanding strength and stiffness to weight ratios

- Good impact strength

- Low resin absorption

- High fatigue resistance

- Good fire performance (self-extinguishing)

- High sound and thermal insulation

- Good styrene resistance

Applications & Uses

- Applications

- Composites End Use

- Composites Processing Methods

- Application

- Marine: Hulls, decks, bulkheads, superstructures, interiors

- Road and Rail: Roof panels, interiors, floors, doors, partition walls, side skirts, front-ends

- Wind energy: Rotor blades, nacelles, turbine generator housings

- Aircraft and Aerospace: Interiors, radomes, galley carts, general aviation (fuselage and wing)

- Recreation: Skis, snowboards, surfboards, wakeboards, canoes, kayaks

- Industrial: Tooling, tanks, ductwork, containers, covers

- Processing

- Contact molding (hand/spray)

- Vacuum infusion

- Resin injection (RTM)

- Adhesive bonding

- Pre-preg processing

- Thermoforming

Properties

- Mechanical Properties

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Compressive Strength Perpendicular to the Plane | 0.90 (130) | N/mm² (psi) | — |

| Compressive Modulus Perpendicular to the Plane | 69 (10,000) | N/mm² (psi) | — |

| Tensile Strength in the Plane | 1.3 (190) | N/mm² (psi) | — |

| Tensile Modulus in the Plane | 45 (6,530) | N/mm² (psi) | — |

| Shear Strength | 0.85 (123) | N/mm² (psi) | — |

| Shear Modulus | 22 (3,190) | N/mm² (psi) | — |

| Shear Elongation at Break | 16.0 | % | — |

| Value | Units | Test Method / Conditions | |

| Density | 60 (3.7) | kg/m³ (lb/ft³) | — |

| Thermal Conductivity at Room Temperature | 0.031 (0.21) | W/m.K (BTU.in/ft2.hr.°F) | — |

| Standard Sheet Width | 1150 (45.3) | mm ± 5 (in ± 0.2) | — |

| Standard Sheet Length | 2450 (96.5) | mm ± 5 (in ± 0.2) | — |

| Standard Sheet Thickness | 5 to 70 (0.2 to 2.8) | mm ± 0.5 (in ± 0.02) | — |