Knowde Enhanced TDS

Identification & Functionality

- Core Type

- Composite Materials Functions

- Technologies

- Product Families

Features & Benefits

- Materials Features

- Product Highlights

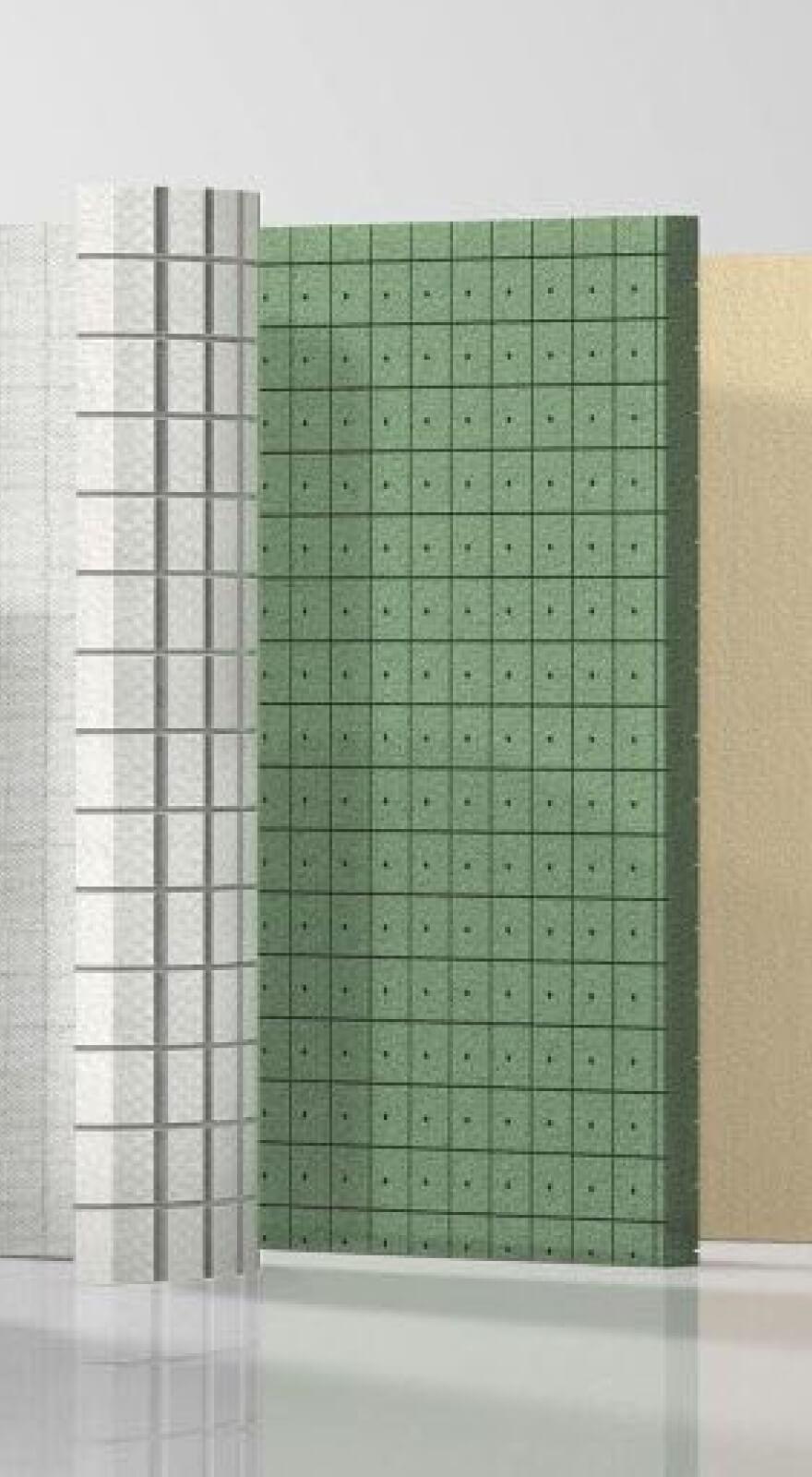

- Stand alone product – does not need face sheets

- High flexural strength and stiffness

- Replacement for wood and plywood

- Good fastener pull-out strength

- High heat resistance

- Compatible with a wide range of resins and adhesives

- Dimensionally stable

- High styrene resistance

- Very low water absorption

- Non biodegradable

- Excellent chemical resistance

Applications & Uses

- Applications

- Composites End Use

- Composites Processing Methods

- Application

- Wind energy: Floors, soles, bulkheads, transoms, stringers, engine beds, interiors, local reinforcements, tooling and molds

- Road and Rail: Floors, sidewalls, roofs, engine covers, interior panels

- Industrial: Covers, tanks, containers, floors, tooling and molds, concrete pouring forms, architectural panels, tub and shower enclosures

- Processing

- Contact molding (hand/spray)

- Resin infusion / injection (VARTM / RTM)

- Adhesive bonding

- Pre-preg processing

- Processing molding (GMT)

Properties

- Mechanical Properties

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Compressive Strength Perpendicular to the Plane | 1.5 (214) | N/mm² (psi) | — |

| Compressive Modulus Perpendicular to the Plane | 72 (10,538) | N/mm² (psi) | — |

| Shear Strength | 0.9 (125) | N/mm² (psi) | — |

| Shear Modulus | 44 (6,330) | N/mm² (psi) | — |

| Flexural Strength | 22 (3,245) | N/mm² (psi) | — |

| Flexural Modulus | 1,870 (271,070) | N/mm² (psi) | — |

| Value | Units | Test Method / Conditions | |

| Standard Sheet Width | 1219 (48) | mm (in) | — |

| Standard Sheet Length | 2438 (96) | mm (in) | — |

| Density | 320 (20) | kg/m² (lb/ft³) | — |

| Standard Sheet Thickness | 20 to 50 (¾ to 2) | mm (in) | — |