Knowde Enhanced TDS

Identification & Functionality

- Core Type

- Composite Materials Functions

- Technologies

- Product Families

Features & Benefits

- Materials Features

- Product Highlights

- Fulfills most stringent fire requirements

- Operating temperature from -194 °C to +160 °C (-317 °F to +320 °F)

- Remains ductile at cryogenic temperatures

- Excellent dielectric properties (radar outstanding transparency)

- Very low moisture absorption

- Good fatigue resistance

- High impact resistance (non-brittle failure mode)

- Thermoformable

- Good sound and thermal insulation

Applications & Uses

- Applications

- Composites Processing Methods

- Application

- Aircraft and Aerospace: Interiors, cockpit doors, cryogenic tanks, insulating panels, radomes, helicopter rotor blades, general aviation (fuselage and wing)

- Road and Rail: Front-ends, side skirts, roof panels, interiors

- Marine: Fast-ferries, fire resistant interiors, radomes

- Defense: Naval superstructures, antennas, combat communication systems

- Industrial: High temperature tooling, radomes, x-ray tables

- Processing

- Adhesive bonding

- Thermoformable

- Pre-preg processing (up to 180 °C, 355 °F)

- Hot press molding

- Thermoplastic processable

- Automated tape laying (ATL/CTL)

Properties

- Mechanical Properties

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Compressive Strength Perpendicular to the Plane | 1.1 (160) | N/mm² (psi) | — |

| Compressive Modulus Perpendicular to the Plane | 62 (9,000) | N/mm² (psi) | — |

| Tensile Strength in the Plane | 2.0 (290) | N/mm² (psi) | — |

| Tensile Modulus in the Plane | 54 (7,800) | N/mm² (psi) | — |

| Shear Strength | 1.1 (160) | N/mm² (psi) | — |

| Shear Modulus | 23 (3,300) | N/mm² (psi) | — |

| Shear Elongation at breat | 23.0 | % | — |

| Impact Strength | 1.3 (0.62) | kJ/m² (Ft.lb/in²) | — |

| Value | Units | Test Method / Conditions | |

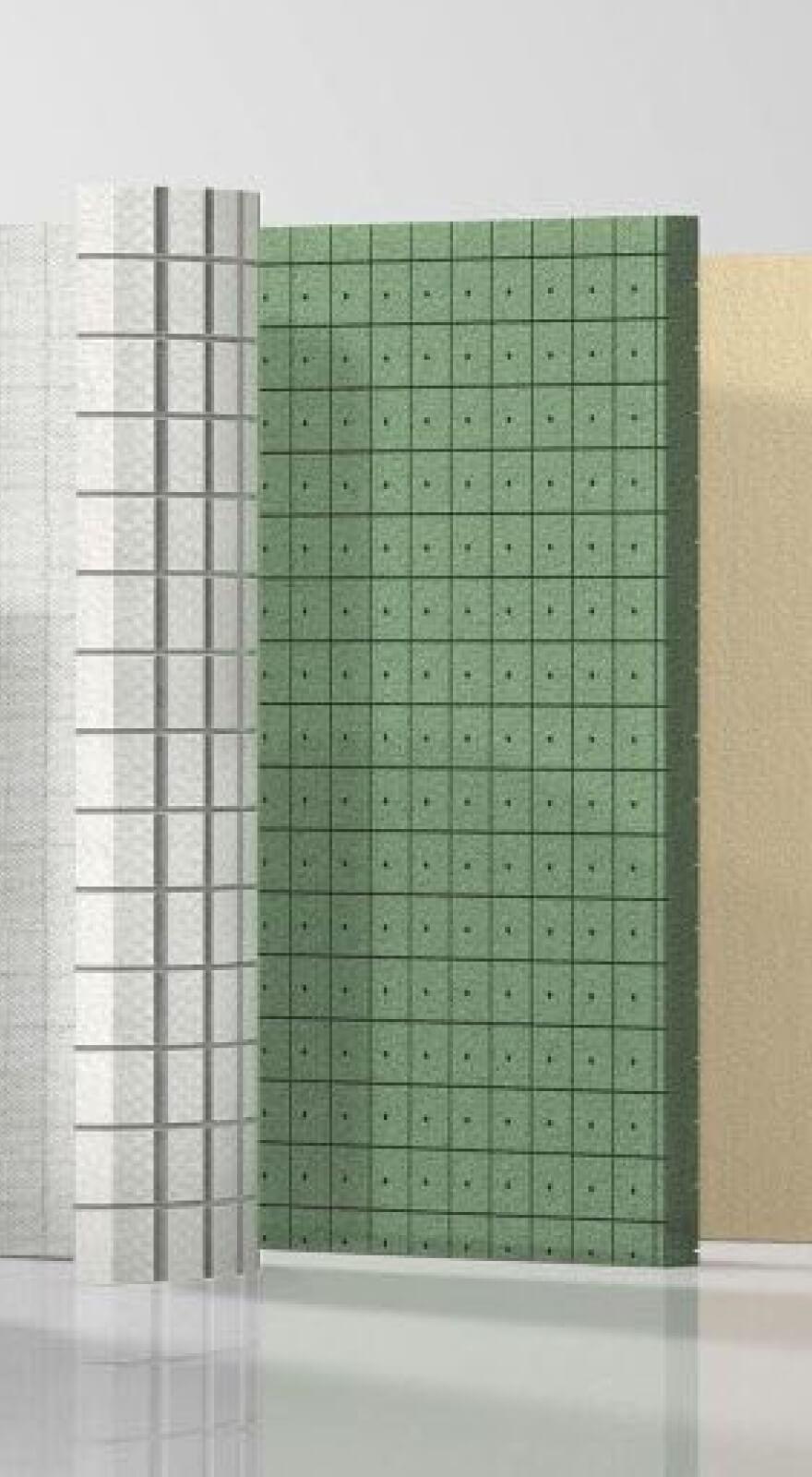

| Standard Sheet Thickness | 3 to 60 (1/8 to 2.3) | mm ± 0.5 (in ± 0.02) | — |

| Color | Off White | — | — |

| Density | 80 (5.0) | kg/m³ (lb/ft³) | — |

| Thermal Conductivity at Room Temperature | 0.037 (0.26) | W/m.K (BTU.in/ft2.hr.°F) | — |

| Standard Sheet Width | 1200 (57.2) | mm ± 5 (in ± 0.2) | — |

| Standard Sheet Length | 2700 (106.3) | mm ± 5 (in ± 0.2) | — |