Knowde Enhanced TDS

Identification & Functionality

- Core Type

- Composite Materials Functions

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Materials Features

- Product Highlights

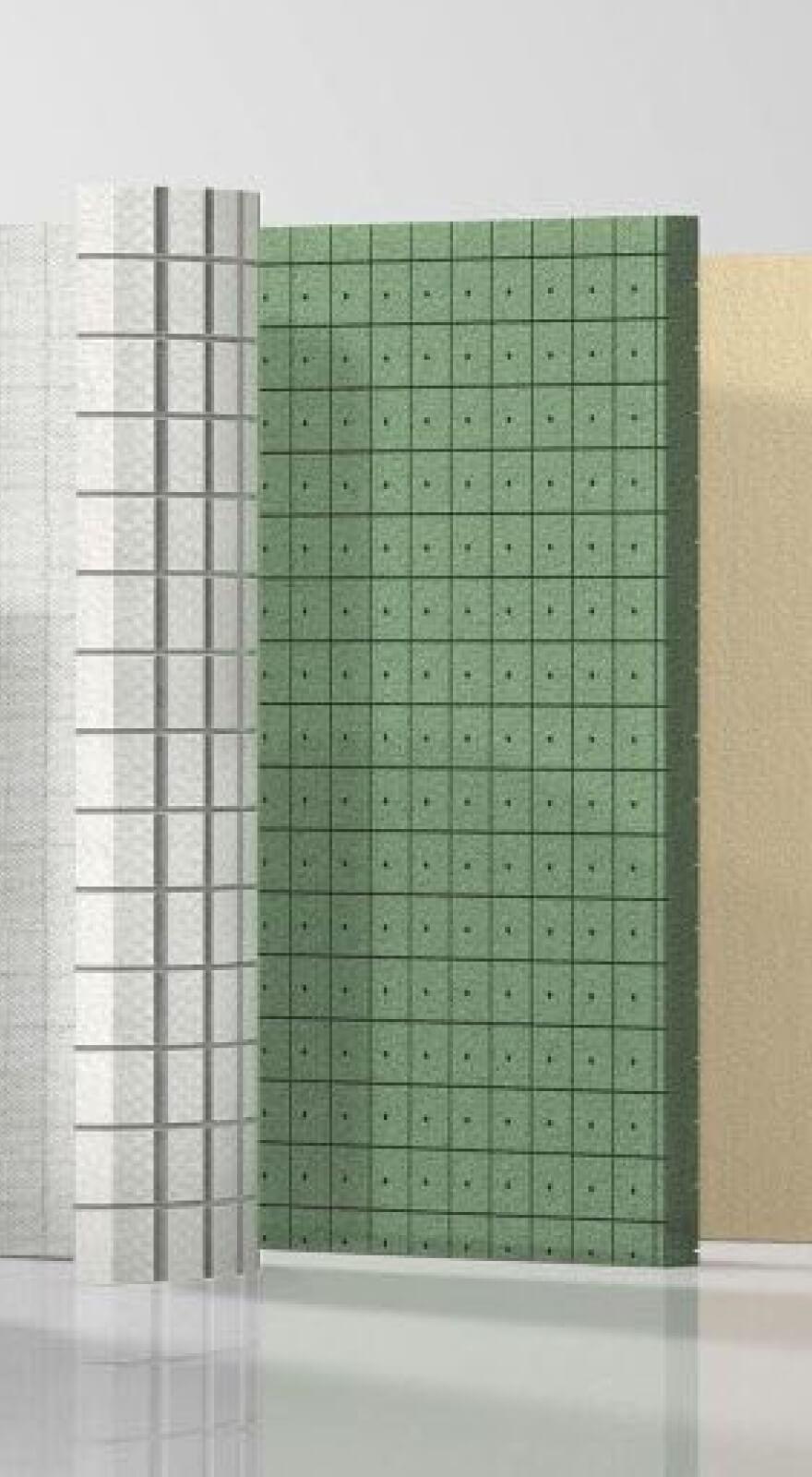

- Very high compression and shear properties

- Outstanding fatigue strength

- Homogeneous cell structure

- Easy to process with all types of resin and lamination processes

- High process temperature up to 150 °C (short peaks up to 180 °C)

- Good adhesion (skin-to-core bond)

- Excellent long term thermal stability, up to 100 °C (212 °F)

- No water absorption

- Recyclable and recycled material

- Highly consistent material properties

- Comprehensive material traceability (machine-readable batch information on each foam sheet)

Applications & Uses

- Applications

- Composites Processing Methods

- Application

- Road: Structural and semi-structural parts in interior and exterior of cars Sidewalls, floors, skirts/covers of trucks.

- Wind energy: Blades (shear webs & shells), nacelles

- Marine: Hulls, decks, superstructures, bulkheads, stringers, interiors

- Industrial: Covers, containers, X-ray tables, sporting goods

- Processing

- Contact molding (hand/spray)

- Vacuum infusion (VARTM)

- Resin injection (RTM)

- Adhesive bonding

- Pre-preg processing

- Compression molding (GMT, SMC)

- Thermoforming

Properties

- Mechanical Properties

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Compressive Strength Perpendicular to the Plane | 1.2 (174) | N/mm² (psi) | — |

| Compressive Modulus Perpendicular to the Plane | 105 (15‘225) | N/mm² (psi) | — |

| Tensile Strength Perpendicular to the Plane | 2.0 (280) | N/mm² (psi) | — |

| Tensile Modulus Perpendicular to the Plane | 150 (21‘760) | N/mm² (psi) | — |

| Shear Strength lengthwise | 1.1 (160) | N/mm² (psi) | — |

| Shear Strength crosswise | 0.8 (116) | N/mm² (psi) | — |

| Shear Modulus lengthwise | 34 (4‘931) | N/mm² (psi) | — |

| Shear Modulus crosswise | 17.5 (2‘538) | N/mm² (psi) | — |

| Shear Elongation at Break | 20.0 | % | — |

| Value | Units | Test Method / Conditions | |

| Density | 100 (6.2) | kg/m³ (lb/ft³) | — |

| Thermal Conductivity at Room Temperature | tbd (tbd) | W/m.K (BTU.in/ft2.hr.°F) | — |

| Standard Sheet Width | 1005 (39.6) | mm ± 5 (in ± 0.2) | — |

| Standard Sheet Length | 2440 (96) | mm ± 5 (in ± 0.2) | — |

| Standard Sheet Thickness | 5 to 45 (0.2 to 1.8) | mm ± 0.5 (in ± 0.02) | — |