Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Polymer Name

- Reinforcement Material

- Composite Materials Functions

- Technologies

- Product Families

- Type

Epoxy resin, which contains a hardening system.

- Appearance

A resin is in the form of yellowish transparent foil, 0.1-0.7 mm thick (according to the customer request). It is flexible and shapeable at indoor or increased temperature.

Features & Benefits

- Materials Features

Applications & Uses

- Applications

- Compatible Reinforcements

- Composites End Use

- Composites Processing Methods

- Usage

Epoxy resin in the form of foil is designed for patent Letoxit® Foil Technology (LF Technology). LFTechnology is a dry lamination technique, which is suitable especially for production of laminatestructures with exactly defined reinforcement and resin content. If it is necessary to increase theamount of resin in a certain place, it is also possible to combine epoxy resin Letoxit® Foil withprepregs.

Letoxit® Foil LFX 023 can be applied for all types of reinforcement. Various types of glass, carbon orKevlar fabrics or their combinations are mostly used. Unidirectional oriented reinforcements or 3Dfabrics can be used, too. LFX 023 is suitable especially for production of sandwich structures andhoneycomb constructions. The produced laminate has very good mechanical properties understress in temperature range from -75°C to +100°C. Therefore it is used for manufacturing of aircraftparts and transport vehicles.- Lamination technique

Laminate is made by laying foils and reinforcement in order to keep the required predeterminedreinforcement/resin ratio. Required shape corresponding to the shape of laminated surfaces is cutout with scissors, knife or other tool from the Letoxit® Foil resin. Covering paper is pulled off thefoil and the resin is put on the upper layer of the reinforcement. The resin foil pushed against thereinforcement a little and smoothened to avoid reinforcement folds. The reinforcement has to beloosened well to fill the mold perfectly. The second covering polyethylene foil is then pulled offand next reinforcement layer is applied. These steps are repeated until the desired amount ofreinforcement layers is reached. It is recommended to work at the manipulation temperature –temperature range, which specifies processability of Letoxit® Foil. Below the manipulationtemperature, this material is too brittle and it breaks and it is too shapeable and adhesive abovethis temperature range. The manipulation temperature is thus 15-35°C; the best processability isbetween 20 and 30°C. It is suitable to use hot-air gun for assembling of more difficult compositionsor shaped surfaces, especially when warm table cannot be used.

It is possible to use either more layers of reinforcement alternately with the Letoxit® Foil resin or touse one thick layer of Letoxit® Foil resin and several layers of reinforcement. It is necessary to haveat least one layer of reinforcement between the mold and the layer of Letoxit® Foil resin. Theamount of Letoxit® Foil has to be high enough to fill up the vacant space in the reinforcementstructure. Minimal amount of resin content can be calculated with following formula: mLF /ρLF + mR /ρR = tC where mLF is a Letoxit® Foil area weight (g/m2), ρLF is a Letoxit® Foil density (g/cm3), mR (g/m2) is areinforcement area weight (g/m2), ρR is reinforcement density (g/cm3) and tC is composite thickness(µm). Area weight can be calculated for all layers of reinforcement or Letoxit® Foil. Examples ofsome reinforcement density can be found in the table.

Type of reinforcement Density (g.cm3) E-glass 2.58 S2-glass 2.46 Carbon 1.76 Air has to be evacuated from the composition reinforcement-Letoxit® Foil before curing. Requiredpressure is 0.075-0.09 MPa. The composition has to be evacuated longer to achieve requiredpressure value in all parts of the laminate. It is important particularly for large products or productswith high number of layers. It is recommended to perforate the Letoxit® Foil with a spiked roller; itallows better evacuation of air before curing. The evacuated composition is cured in the mold atincreased temperature under vacuum or in a press or autoclave.

Resin can be also added to prepregs by laying the Letoxit® Foil to a specified place, whereincreased amount of resin is needed. The processing of this composition is the same as in the caseof prepregs. Careful evacuation of air and sufficient pressure difference reach perfect impregnationof fibers after temperature rise; thus the quality of the resulting composite is comparable withprepregs without necessity of autoclave use.

Properties

- Color

Technical Details & Test Data

- Curing

Letoxit® Foil LFX 023 resin is usually cured at temperature 120-125°C for 60 minutes. Laminate is fixed with pressure 0.075-0.09 MPa during curing. Two processes occur during temperature rise of the foil:

1/ The viscosity of Letoxit® Foil decreases with increasing temperature and the dry reinforcement is being impregnated

2/ Epoxy resin starts to cure (effect of hardeners) after temperature rise

Therefore it is necessary to ensure sufficient time for impregnation of dry reinforcement during curing at increased temperature before Letoxit® Foil reaches the gel point when material is not able to flow and thus impregnate the dry reinforcement. For that reason the following temperatures are determined:Impregnation temperature, which is the lowest temperature when the viscosity of Letoxit® Foil is low enough to impregnate the dry reinforcement. In the case of Letoxit® Foil LFX 023, the impregnation temperature is 80°C. Impregnation is easier at higher temperatures, but the time for resin flow is shorter.

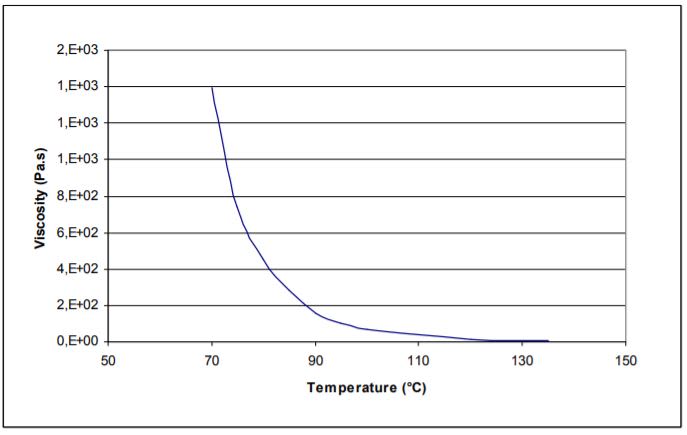

Curing temperature, which is the temperature when resin is cured at certain time. Fig.1: Dependence of viscosity on temperature

Fig.1: Dependence of viscosity on temperatureCuring time is counted from the moment when the temperature within the produced laminate reaches curing temperature. No volatile compounds are released from laminate during preparation or curing. Laminated can be also cured at lower temperature, see following figure and table, which contain curing temperatures and properties.

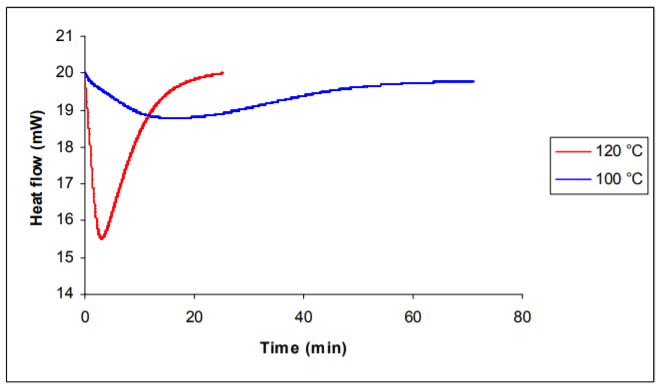

Fig. 2: Dependence of reaction rates on time at constant curing temperatures 100 and 120°C. Measured at DSC.

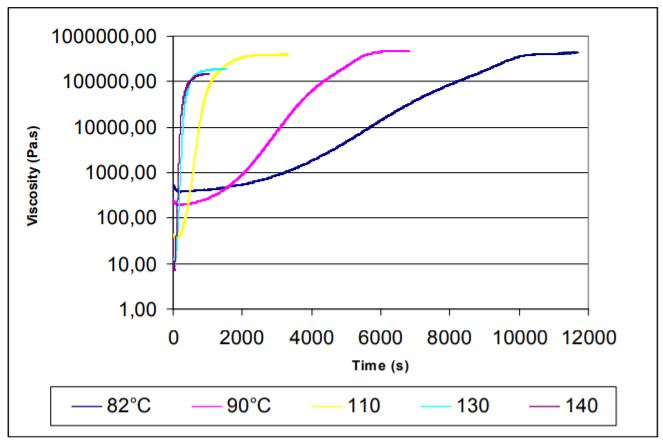

Fig. 3: Dependence of viscosity on time at different curing temperaturesIt is necessary to keep the composition at the curing temperature for at least the minimal curing time. It is necessary to verify that the curing temperature is reached within whole cross-section of the cured composition. Temperature inside the cured composition can be measured with e.g. thermocouple.

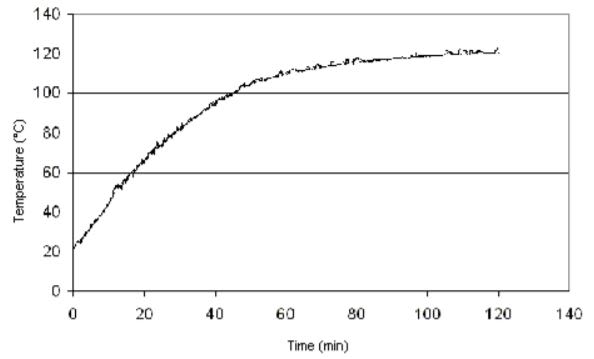

Fig. 4: Dependence of temperature inside the composition carbon fabric-Letoxit® Foil 2.3mm thick. The composition was cured under vacuum in a steel mold at 120°C laid in a drying kiln.- Properties

Properties of Letoxit® Foil LFX 023

Density of uncured resin (g/cm3) 1.19 1.19 1.19 Curing temperature (°C) 90 120 140 Minimal curing time (min) 150 20 15 Recommended curing time (min) 240 60 30 Properties of pure resin* Density (g/cm3) 1.19 1.19 1.19 Shrinkage (%) 0.42 Hardness Barcol 18-19 18-19 18-19 Tg (°C) 95 95 95 Maximal flexural stress (MPa) 125 120-125 90 Flexural modulus of elasticity (GPa) 3-3.1 3-3.1 3-3.1 Impact strength (kJ/m2) 40 45-50 10 *Stated properties of cured resin were measured after curing at given temperature and recommended curing time

Composite properties reinforced with glass *

Density (g/cm3) 1.71 Resin content (%) 43.5 Maximal flexural stress (MPa) 540 Flexural modulus of elasticity (GPa) 18.9 * Properties of cured composite were measured after curing at given temperature and recommended curing time. Composite constitution: 12 layers of glass fabric - twill weave, 163 g/m2, and 5 layers of Letoxit® Foil LFX 023, 300 g/m2.

Composite properties reinforced with carbon *

Density (g/cm3) 1.45 Resin content (%) 41 Maximal flexural stress (MPa) 820 Flexural modulus of elasticity (GPa) 47.5 * Properties of cured composite were measured after curing at given temperature and recommended curing time. Composite constitution: 12 layers of carbon fabric - twill weave, 211 g/m2, and 10 layers of Letoxit® Foil LFX 023, 200 g/m2.

The composition produced under the LF Technology can be cured to lower conversion degree, app. 70% and post-cured outside the mold. However, the composition that is not cured properly is very brittle!

Packaging & Availability

- Packaging Type

- Packaging

The resin is delivered in the form of foil, 250 mm or 1000 mm width, which is protected by a polyethylene foil from one side and isolating paper from the other side. It is winded up on the hollow with the total weight up to 10 kg (usually 5 kg rolls are supplied – according to the customer request).

Storage & Handling

- Storage

Without the change of properties, the resin can be stored for 1 month at +20°C, for 3 months at 5°C and up to 1 year for –18°C. The temperature +30°C mustn’t be crossed during transport and storage.