Knowde Enhanced TDS

Identification & Functionality

- Product Type

- Technologies

- Product Families

- Product Attributes

Contact with foodstuffs Yes, according to EC 1935/2004 and

FDA, 21 CFR 175.300Materials suitable for coatings Steel, Stainless steel, Aluminum Limitation Use of sharp tools will damage the coating

Applications & Uses

- Applications

- Uses

- Accofal has been in use for many years and has served a wide variety of purposes on surfaces where excellent non-stick properties, ease of cleaning and low friction are important. The coating is widely used in the foodstuffs industry, for example in equipment used in marzipan figure manufacture and in fast-food units. In addition, the coating is well suited to paper, textiles, and graphical industry rollers and in chutes used in powder transport.

- Because of its high temperature operating threshold (up to 260°C) the coating can also be used in plastic welding, and despite a relatively low coating thickness it is also well suited to coating objects which require protection from mild corrosion.

Properties

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Layer thickness | 30 – 80 | μm | — |

| Range of temperature (Continously) | -25 - +260 | °C | — |

| Coefficient of friction against steel | 0.2 -0.3 | — | — |

Technical Details & Test Data

- Technical Information

- Accofal 2G54 is black, the coating has a smooth and semi-glossy surface. In order to achieve optimal adhesion and thereby increase product lifetime, the object to be coated should be cleaned before beginning the coating process. In addition, the object to be coated should be sand-blasted to remove any impurities and ensure optimal coating adhesion. The electrostatic coating process ensures that even complex objects achieve total and uniform coating thickness.

- Damaged coating cannot be repaired on site but must be returned to Accoat for re-coating.

- The coating is relatively soft and use of sharp tools and similar equipment can cause damage. We recommend that employees who work with products coated with Accofal 2G54 are informed of this and that they are provided with tools which will not damage the coating, e.g. plastic putty knives for use when working with paint and varnish.

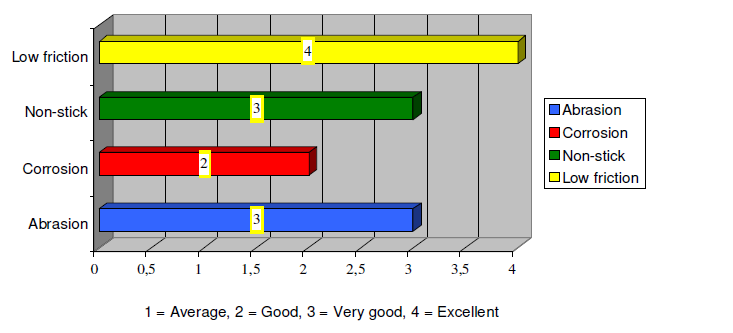

- Significant Properties

Safety & Health

- Safety Precautions

Heating to over 300°C will result in the release of acidic gasses which can be poisonous. Do not weld or perform similar operations on the metal close to coated areas. Old coating is best removed mechanically, e.g. by sandblasting.