Knowde Enhanced TDS

Identification & Functionality

- Product Type

- Technologies

- Product Families

- Product Attributes

Contact with foodstuffs Yes, EC 1935/2004 Materials suitable for coatings Steel, Stainless steel, Aluminum Limitation Use of sharp tools will damage the coating

Applications & Uses

- Markets

- Uses

- Accoflon 1C is an excellent all-round coating, as regards the most common Fluoroplast coating properties. Accoflon 1C is suitable for use in the foodstuffs industry, for example in dough vats, mixers, conveyer belts, toasters and welding tools. In addition, Accoflon 1C makes an excellent coating for knives, cutting tools and not least vacuum and thermal molders.

- As a result of its excellent all-round properties, Accoflon 1C is also suitable for use with frozen products and freeze-drying trays.

- Accoflon 1C can be strengthened with Accowear, where necessary.

Properties

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Layer thickness | 15 – 30 | μm | — |

| Range of temperature (Continously) | -25 - +250 | °C | — |

| Coefficient of friction against steel | Unknown | — | — |

Technical Details & Test Data

- Technical Information

- Accoflon 1C is dark gray and has a semi-matte finish. In order to achieve maximal attachment, and thereby extend product lifetime, rinse and sandblast the product to be coated prior to coating in order to remove impurities and to ensure optimal attachment.

- Damaged coating cannot be repaired on site but must be returned to Accoat for re-coating. Use of sharp tools and similar equipment can damage the coating. We recommend that employees who work with coated tools etc. be informed that the coating can be damaged by the use of sharp items such as knives, chisels and screwdrivers.

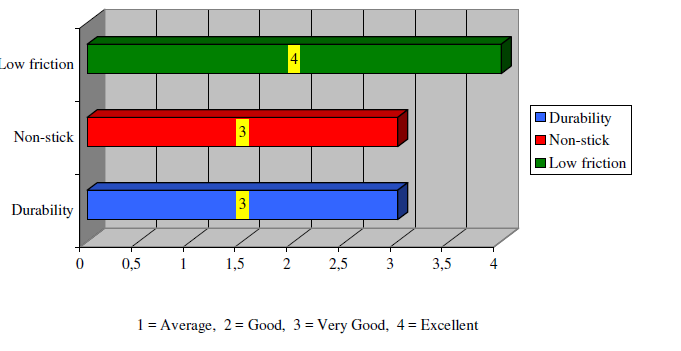

- Significant Properties

Safety & Health

- Safety Precautions

Heating to over 300°C will result in the release of acidic gasses which can be poisonous. Do not weld or perform similar operations on the metal close to coated areas. Old coating is best removed mechanically, e.g. by sandblasting.