Knowde Enhanced TDS

Identification & Functionality

- CASE Ingredients Functions

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- CASE Ingredients Features

Applications & Uses

- Applications

- Compatible Substrates & Surfaces

- Usage Recommendations

- EPOXOL® CA118™ can be used as drop-in replacement of commonly used alcohol esters, glycol ethers, and low VOC coalescing agents on a lb-lb basis with equal or better coalescing performance.

- Reduction of usage levels may improve some desired properties such as scrub and block resistance.

- Customers should use a ladder trial to determine the optimum level of ACS CA118™ to be used in any formulations where a coalescent or plasticizer isreplaced.

Properties

- Color

- Physical Form

- Appearance

- Clear liquid

- Physical Properties

| Value | Units | Test Method / Conditions | |

| Viscosity (25°C) | 20 | cps | ASTM D2196-10 |

| Moisture | max. 0.15 | % | ASTM E1064 |

| Active Matter | min. 99.5 | % | Calculated |

| Density (25°C) | 7.965 - 7.975 | lbs./US gal | ASTM D4052 |

| Pour Point | 6 - 9 | °C | ASTM D6749 |

| Cloud Point | 6 | °C | ASTM D5773 |

| Flash Point | min. 190 | °C | ASTM D93 |

| Boiling Point (0.4 torr) | 147 | °C | ADM INTERNAL |

| Bio-based material content | 95 | % | D-6866-12/Method B |

| Refractive Index (25°C) | 1.453 | — | ADM INTERNAL |

| VOC | 0 | % | ASTM D6886-14 |

Regulatory & Compliance

- Certifications & Compliance

- Inventory Information

Registry Status Country TSCA Listed United States

IECSC Listed China DSL Listed Canada EINECS Listed Europe ECL Listed Korea

Technical Details & Test Data

- Epoxol® CA118 PLASTICIZER Vs. Benzyl Butyl Phthalate

Introduction/Background

Epoxol® CA118 would be evaluated as a plasticizer versus Benzyl Butyl Phthalate2 (BBP) in a caulking compound formulation3 using acrylic latex4.

Conclusions

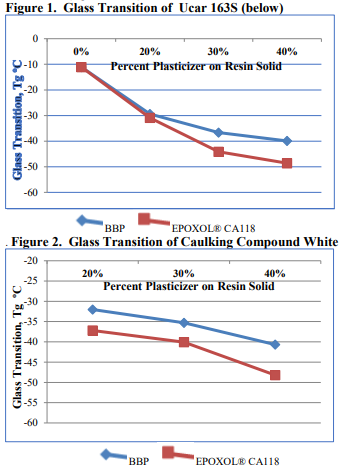

Epoxol® CA118 showed better plasticizing property than Benzyl Butyl Phthalate. Amount of Epoxol® CA118 could be reduced by about 35% to 50% to be comparable with BBP. To completely evaluate performance of Epoxol® CA118 in a caulking compound, the right mixing equipment should be used in preparing the samples, and various testing procedures based on ASTM standards should be performed.

Results and Discussion

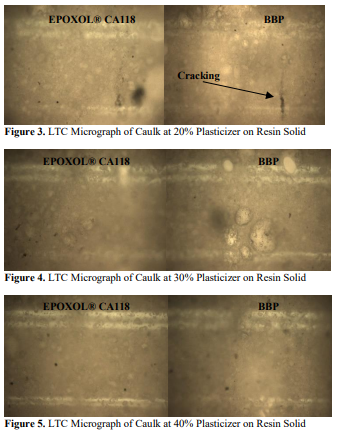

Epoxol® CA118 showed better plasticizing property as shown by its low glass transition (Figure 1) than BBP at standard dosage of 40% as recommended on the caulk formulation3 . To be comparable with 40% BBP, it would need about 27% Epoxol® CA118 to achieve at least similar glass transition. Similarly, in a caulking compound formulation, as shown in Figure 3, it would need only about 30% Epoxol® CA118 to achieve a glass transition similar to BBP at 40%.

The film formation by low temperature coalescing (LTC) method at 20% plasticizer was complete for Epoxol® CA118 while BBP showed a small crack (Figure 3, as shown by arrow). BBP and Epoxol® CA118 were comparable at 30% and 40% (Figures 4 and 5).

Packaging & Availability

- Country Availability

- Regional Availability

Storage & Handling

- Storage and Handling

- Store in the original unopened container. If the container is opened use entire contents as soon as possible. Reseal container tightly.

- Product should be stored at temperatures between 10 and 50°C. Do not allow to freeze.

- Congealed product should be warmed completely to 20°C before use. Vent container while warming.

- Shelf life is a minimum of 36 months when stored as recommended in the original unopened container