Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Product Type

- Technologies

- Product Families

- Generic Type

Chain stop alkyd

Features & Benefits

- Ready-to-Use Product Features

- Features

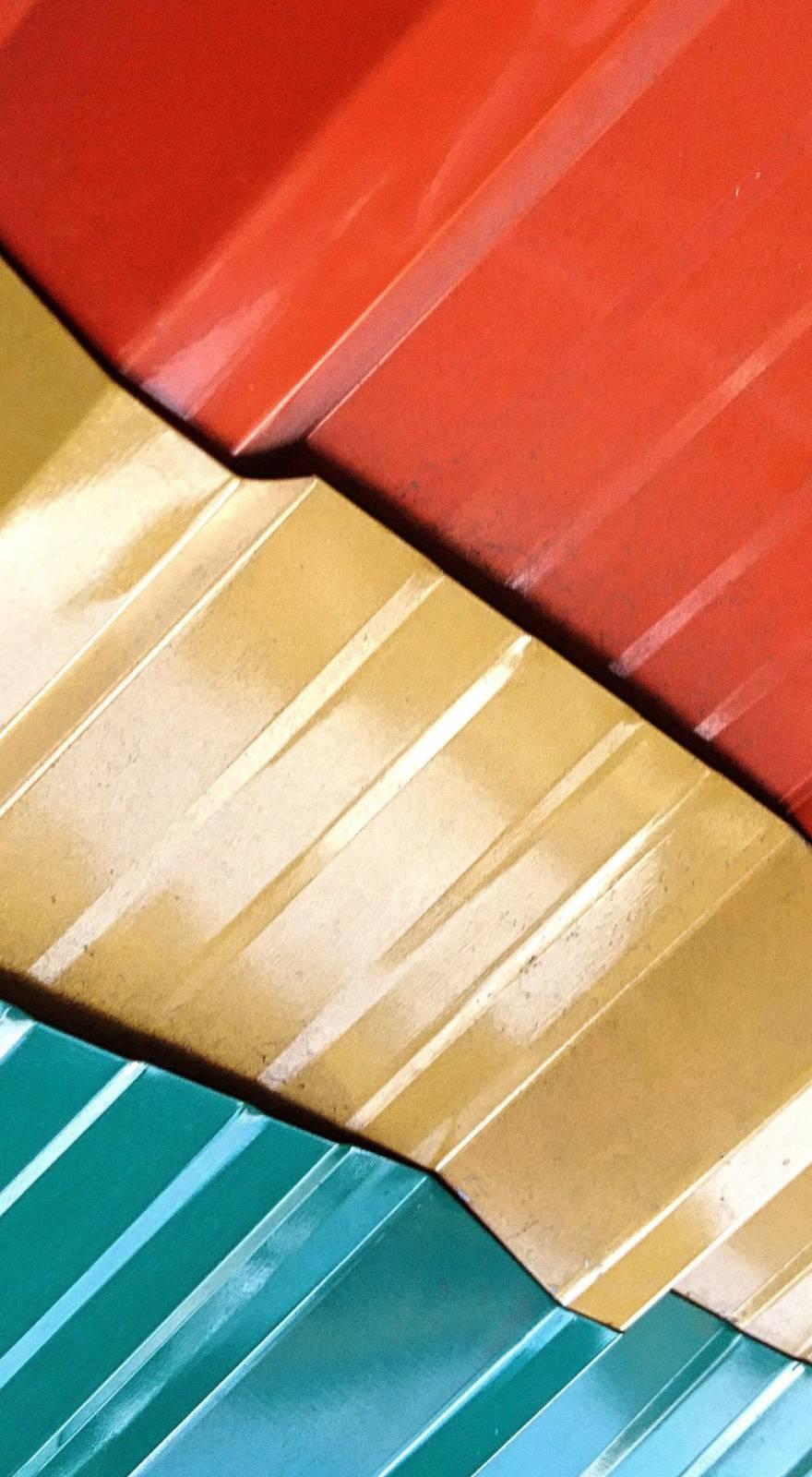

- High Gloss

- Fast Drying

- Can be applied Direct-to-Metal

- Available in a full range of colors

Applications & Uses

- Applications

- Substrate & Surface Preparation

- Must be clean and dry. Any dirt, dust, oil, contaminants, loose rust or loose mil scale must be removed.

- Immersion Carbon Steel: Not Recommended

- Non-Immersion Carbon Steel: Minimum SSPC-SP3 Power tool Cleaning. For optimum performance SSPC- SP6 Commercial Blast, surface profile 1.5-3.0 Mil.

- Galvanized Steel: Not recommended

- Previously painted surfaces: Surface must be sufficiently roughened, either by abrasive blasting or mechanical abrasion. Surface must attain a minimum 3B rating in accordance with ASTM D3359 “X-Scribe” test. Apply a test patch to check compatibility, prior to primary application.

- Primer: APCO 215QP Quick Dry Primer, 245FP Universal Primer, 351 Epoxy Primer

- Application Equipment

Spray Application:

- Conventional: Pressure pot with dual regulators, 3/8” I.D. material hose, Binks 2001 Gun w/66 series nozzles and 565 needle.

- Airless: Graco 36:1 Min. 1⁄4” material line. Tip size .013. Output PSI- 3000-3600

Brush & Roller: Touch up only

- Brush: Natural Bristle

- Roller: 1⁄4” Nap cover with Phenolic Core

- Mixing & Thinning

Components: One

Mixing: Power mix to uniform color & consistency

Thinning:- Spray: Up to 12 oz/gal with S100

- Application

- Pre-application: Flush all equipment with thinner S100

- Temperature: Application range from 40°F-110°F surface temperature. Do not apply below 40°F.

- Method: Apply one coat maintaining a wet edge to achieve a WFT of 4-6 Mils. Maximum performance will be achieved with two coats totaling 4-6 mils DFT.

- Application Continued

Inspection: Visually inspect film to ensure adequate coverage.

Clean up & disposal: After use immediately flush all equipment with thinner S108 or M.E.K. Dispose of all containers, solvents and unused materials in accordance with all local, state and federal regulations.

Curing schedule: Times based upon 75°F

- Dry to touch: 20 minutes

- Dry through: 48 hours

A critical re-coat time may occur between 2 and 48 hours at room temperature. This may fluctuate depending on temperature and film thickness. Test small inconspicuous area first.

Dry times are greatly affected by weather conditions and film thickness.

Properties

- Typical Properties

- Permanence Properties

- Performance Properties

| Value | Units | Test Method / Conditions | |

| Solids Content | 40.0 | % by Volume | - |

| VOC Value | 4.3 | lbs/gal | EPA Method 24 |

| Value | Units | Test Method / Conditions | |

| Theoretical Coverage (3 mil DFT) | 256 | ft² |

| Value | Units | Test Method / Conditions | |

| Theoretical Coverage (mil) | 641 | ft² |

Packaging & Availability

- Packaging Type

- Packaging & Handling:

- Unit sizes: Ones, Fives and Drums

- Shipping Weight: 10 lbs/gal Unit