Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Product Type

- Technologies

- Product Families

- Generic Type

High Solids Alkyd

Features & Benefits

- Labeling Claims

- Ready-to-Use Product Features

- Features

- High Gloss

- High solids, VOC complaint

- Fast Drying

- Can be applied Direct-to-Metal

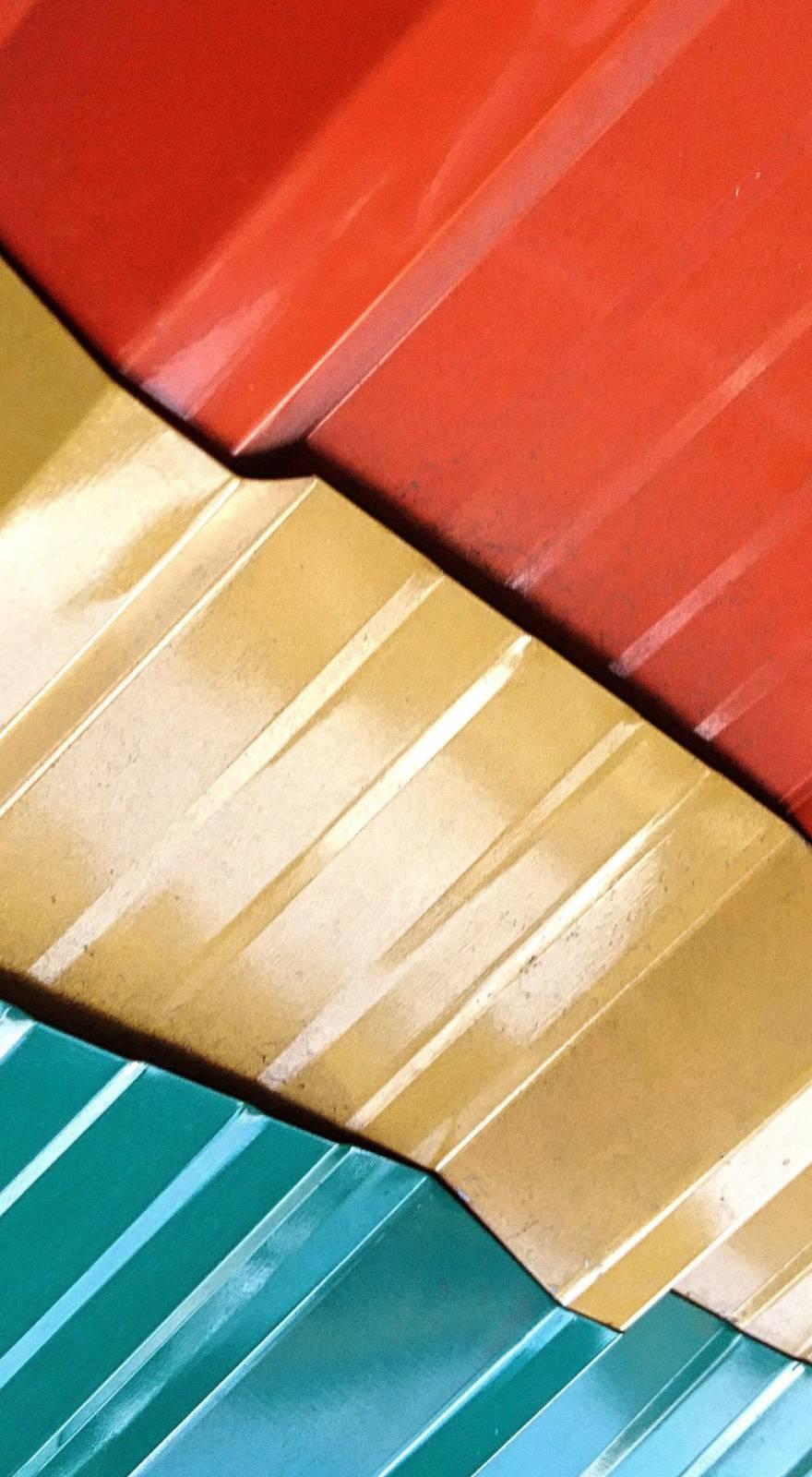

- Available in a full range of colors

- Mixing & Thinning

Components: One

Mixing: Power mix to uniform color & consistency

Thinning:

Spray: Up to 12 oz/gal with S100

Applications & Uses

- Markets

- Substrate & Surface Preparation

- Must be clean and dry. Any dirt, dust, oil, contaminants, loose rust or loose mil scale must be removed.

- Immersion Carbon Steel: Not Recommended

- Non-Immersion Carbon Steel: Minimum SSPC-SP3 Power tool Cleaning. For optimum performance SSPC- SP6 Commercial Blast, surface profile 1.5-3.0 Mil.

- Galvanized Steel: Not recommended

- Previously painted surfaces: Surface must be sufficiently roughened, either by abrasive blasting or mechanical abrasion. Surface must attain a minimum 3B rating in accordance with ASTM D3359 “X-Scribe” test. Apply a test patch to check compatibility, prior to primary application.

- Primer: APCO 245FP Universal Primer, 351 Epoxy Primer

- Application Equipment

Spray Application:

- Conventional: Pressure pot with dual regulators, 3/8” I.D. material hose, Binks 2001 Gun w/66 series nozzles and 565 needle.

- Airless: Graco 36:1 Min. 1⁄4” material line. Tip size .013. Output PSI- 3000-3600

Brush & Roller: Touch up only

- Brush: Natural Bristle

- Roller: 1⁄4” Nap cover with Phenolic Core

- Application

- Pre-application: Flush all equipment with thinner S100

- Temperature: Application range from 40F-110F surface temperature. Do not apply below 40F.

- Method: Apply one coat maintaining a wet edge to achieve a WFT of 4-6 Mils. Maximum performance will be achieved with two coats totaling 4-6 mils DFT. A critical recoat time may occur between 2 and 48 hours at room temperature. This may fluctuate depending on temperature and film thickness. Test small inconspicuous area first.

- Application Continued

Inspection: Visually inspect film to ensure adequate coverage.

Clean up & disposal: After use immediately flush all equipment with thinner S108 or M.E.K. Dispose of all containers, solvents and unused materials in accordance with all local, state and federal regulations.

Curing schedule: Times based upon 75°F

- Dry to touch: 6 hours

- Dry through: 18 hours

- Dry to cure: 48 hours

Dry times are greatly affected by weather conditions and film thickness.

Properties

- Typical Properties

- Performance Properties

| Value | Units | Test Method / Conditions | |

| Solids Content | 51.0 | % by Volume | - |

| VOC Value | 3 | lbs/gal | EPA Method 24 |

| Value | Units | Test Method / Conditions | |

| Theoretical Coverage (mil) | 818 | ft² | |

| Theoretical Coverage (3 mil DFT) | 272 | ft² |

Packaging & Availability

- Packaging & Handling:

- Unit sizes: One and Five gallon units

- Shipping Weight: 11 lbs/gal Unit