Knowde Enhanced TDS

Identification & Functionality

- Agrochemical Functions

- Technologies

- Product Families

- Ingredients

Activated Hydrocolloids 78.80% Inert Ingredients 21.2% Total 100.00%

Features & Benefits

- Labeling Claims

- Agrochemicals Features

- Product Highlights

Stick N Stay is a new and innovative utility modifier scientifically formulated to improve the delivery of agricultural chemicals by unleashing the diverse functionality of natural gums. Attune, the makers of Stick N Stay, are relying on over 100 years of experience developing and commercializing natural gums in the food industry as the foundation for launching unique gum combinations to the agricultural market. Natural gums are derived from a wide variety of plants and bacteria and as such, provide tremendous diversity in their functionality. In general, gums work by dramatically altering the physical characteristics of water-based solutions. For example, gums can change the thickness of a solution by trapping water. This functionality is commonly used in the food industry to thicken soups and sauces. Gums also provide adhesion characteristics. Think about how pieces of granola bar are held together or how sesame seeds stay on top of a bagel. Film formation is another excellent functional trait of gums. Creating a strong film is how you form that crunchy coating on the outside of a piece of chewing gum or chocolate candy. While these examples are specific to food, it's easy to see how these important gum functionalities can be applied to agricultural tank mix applications.

The objective here has been to apply this extensive gum knowledge in order to create new and innovative technologies by focusing on:

- Delivering more spray volume to the target,

- Keeping the active ingredient on the target, and

- Maximizing the inherent functionality of the active ingredient

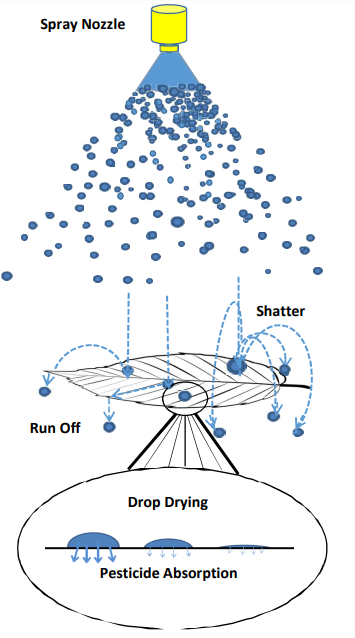

- Proven Science

We believe it is imperative to understand the forces impacting spray tank ingredients starting at the nozzle and continuing all the way through deposition of droplets. Ultimately, we are most focused on ensuring that the active ingredients are capable of performing as intended. This systematic approach is critical to determining which functional attributes are necessary to improve the performance of an agricultural spray by the inclusion of a delivery system. Studies focusing on the impact of changing the physical characteristics of tank mix sprays using natural gum combinations and their subsequent effectiveness have been examined. From this research, several opportunities were identified whereby changing the physical characteristics of tank mix solutions improved agricultural spray delivery and unleashed the full potential of active ingredients.

- Precise Performance

For more than 7 years, Stick N Stay has been extensively evaluated utilizing laboratory, greenhouse, spray chamber, wind tunnel, field research and commercial demonstration trials. The compilation of this extensive research program demonstrates that Stick N Stay enhances the precision of pesticide performance by:

- Demonstrating better spray coverage

- Increasing on target spray volume

- Maximizing the inherent functionality of active ingredients

- Providing resistance to wash off from rainfall or overhead irrigation

- Increase in Wash Off Protection

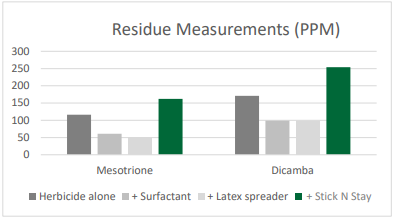

Attune evaluated wash off resistance by spraying leaves with a herbicide mixed with either Stick N Stay or a competitive spreader/sticker adjuvant. After the leaves were allowed to dry, half of the leaves were exposed to 0.25 inches of simulated rainfall. Leaf disks were cut out and residue levels were determined by chemical analysis. In >70% of the head to head evaluations, Stick N Stay provided higher levels of resistance to wash off than the competitive standard.

Treatment Average

% Wash Off Resistance*Pesticide 23.10% Sticker 92.50% Stick N Stay 98.80%

Applications & Uses

- Markets

- Application Technique

- Directions for Use

Stick N Stay is intended for use on a wide variety of crops including: row crops, fruits and vegetables, turf and ornamentals, grasslands and forestry applications. Not for aquatic use. Pesticide manufacturer’s label statements for use should always be followed. When combining with new ingredients or applying to sensitive crops, conduct compatibility and phytotoxicity tests to safeguard against crop damage.Suggested use rates 0.125% to 0.5% (Stick N Stay Volume: Total Spray Volume)

- Mixing

Water should be the first ingredient added to the mix tank. It is recommended that half of the amount of water to be used in the final spray volume should be added and agitated or circulated through the tank. Stick N Stay should then be added to the spray tank with agitation to disperse this utility modifier throughout the tank. Allow Stick N Stay to circulate through the tank for at least 5 minutes to ensure complete dispersion of the utility modifier. Active or other ingredients should then be added as per label recommendations with agitation. Finally, after all ingredients are thoroughly dispersed, the remaining quantity of water should be added to the spray tank and agitated to complete the tank mix formulation.

- Smarter Agriculture

Smarter Agriculture involves getting the most out of every input the farmer employs. And in doing so, ensuring the safety of the workers directly exposed to the ingredients. In that light, Stick N Stay has been developed using only food grade ingredients that have been extensively tested to have the lowest toxicity rating, Category IV. No signal words are required for labeling this product and no special PPE or handling is required. Stick N Stay can be a valuable component of an innovative farming approach.

- Directions for Use

The suggested use rates are 1 pint to 2 quarts of Stick N Stay per 100 gallons of spray volume ( 1.25 liters – 5 liters per 1000 liters of spray volume). For improved spray deposition, use 1 pint to 1 quart of Stick N Stay per 100 gallons (1.25 liters – 2.5 liters per 1000 liters of spray volume). For wash-off prevention, use 1 to 2 quarts of Stick N Stay per 100 gallons (2.5 liters – 5 liters per 1000 liters of spray volume).

- Mixing

Water should be the first ingredient added to the mix tank. It is recommended that half of the amount of water to be used in the final spray volume should be added and agitated or circulated through the tank. Stick N Stay should then be added to the spray tank with agitation to disperse the adjuvant throughout the tank. Allow Stick N Stay to circulate through the tank for at least 5 minutes to ensure complete dispersion of the adjuvant. Active or other ingredients should then be added as per label recommendations with agitation. Finally, after all ingredients are thoroughly dispersed, the remaining quantity of water should be added to the spray tank and agitated to complete the tank mix formulation.

- Better Spray Coverage

Attune compared the relative spray coverage of herbicides mixed with Stick N Stay to those mixed with competitive deposition aids. Water sensitive deposition cards were sprayed in a track spray chamber, allowed to dry, digitally scanned, and analyzed using Media Cybernetics ImagePro software. Coverage was measured as the percent of the card covered by drops. In greater than 80% of 112 head to head comparisons, Stick N Stay provided greater coverage than the leading adjuvant deposition aids.

Properties

- Physical Form

Regulatory & Compliance

- Certifications & Compliance

- Chemical Inventories

- Regulatory

- Classified as a Utility Modifier

- 6 pack toxicology studies completed by Stillmeadow, Inc. in Texas, USA

- All tests report Stick N Stay has very low toxicity

- No mandatory signal words required

- Rating all Category IV’s on the toxicity categories for signal words

Technical Details & Test Data

- Technical Details

Current Challenges

Droplet Size

- Drops <100 microns are drift prone and will evaporate more readily due to high surface to volume ratios

- Excessive evaporation reduces spray volume and can also make drops more prone to drift

Target Contact

Spray Drops are prone to:

- Bounce off

- Run off

- Shatter into smaller drops

Residence Time

- Absorption stops when the drop dries up.

- Spray residues are prone to washoff by overhead irrigation and rainfall

Attune Solutions

Droplet Size

- Increase the viscosity of the solution to reduce the formation of small drops

- Reduce evaporation to increase spray volume to the target

Target Contact

- Create an internal matrix that increases strength of the drop to reduce shatter

- Provide adhesive characteristics to adhere drops to the plant surface

Residence Time

- Increase water binding which slows water loss due to evaporation resulting in an increase in systemic pesticide absorption.

- Create a film as protection from wash off.

- More Spray Volume on the Target

Stick N Stay delivers more spray volume than competitive adjuvants by:

- Reducing small drops being formed at the nozzle,

- Reducing evaporation as drops travel to the plant,

- Reducing the loss due to drop bouncing, shattering and runoff.

Research trials were conducted in which plants were sprayed with a herbicide, herbicide + Stick N Stay, and herbicide + competitive adjuvants. Leaf disks were cut from treated plants and analyzed for herbicide residues. Herbicide sprays using Stick N Stay had up to 3 times more herbicide residues than competitive adjuvants.

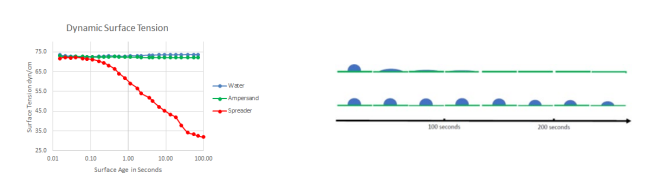

- Increased Absorption Potential

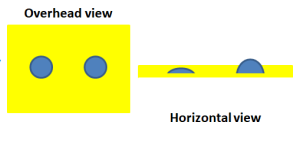

Many active ingredients today are systemic or translaminar which implies that they must be absorbed into the plant for optimum effectiveness. The absorption of most active ingredients stops when drop residues dry on the leaf surface. Consequently, drop evaporation rate plays a significant role in determining the amount of active ingredient that is absorbed into the plant. Drop evaporation is heavily influenced by environmental conditions like temperature and relative humidity as well as droplet characteristics like size and the contact angle of a drop on a leaf. Surface tension of the droplet will dictate how high the contact angle is: higher surface tension = higher contact angle. Sprays with high contact angles will have minimal spread which can increase the amount of time active ingredients have for absorption by as much as 50%. Most competitive deposition aids contain surfactants which quickly reduce a drop’s surface tension causing the drop to spread and thereby accelerating evaporation.

Stick N Stay employs two modes of action to increase the amount of time for active ingredient absorption. First, Stick N Stay is designed to produce droplets with higher contact angles which minimize spread and maximize droplet volumes. Second, Stick N Stay uses humectants to further reduce droplet evaporation rates which in turn increases the time available for the active ingredient to be absorbed into the leaf.

Safety & Health

- Statement of Practical Treatment

- If inhaled: Not expected to be harmful if inhaled. Treat symptomatically.

- If swallowed: Not expected to be harmful if ingested. Drink water to rush system. Consult a physician if symptoms develop.

- If on skin: Not expected to be harmful if exposed to skin. Rinse material with water and launder contaminated clothes before reuse.

- If in eyes: Rinse with water or eyewash solution to remove contaminates. If irritation develops, consult a physician.

- Safety

- Stick N Stay formulated using food grade ingredients

- Application and handling of Stick N Stay is very worker and environmentally friendly. No PPE or special handling required

- All remaining product can be safely disposed using simple triple water rinsing of containers.

Packaging & Availability

- Packaging Type

Storage & Handling

- Storage and Disposal

Storage: Store in a cool dry place in the original container. Do not store near heat or open flame. Keep container tightly sealed. Do not freeze.

Disposal: The ingredients in stick n stay are non-hazardous. Disposal of stick n stay does not require special waste treatment activities. If any active or other ingredient has been added directly to the container, follow the disposal instructions for that ingredient.

Container disposal: The product container should be rinsed and then o_x001f_ered for recycling or reconditioning or disposed of in a sanitary landfill.

- Storage

For best results, store containers above 4֯֯°C. Storage at lower temperatures will result in a thicker solution that may require longer mixing time. Do not allow to freeze.