Knowde Enhanced TDS

Identification & Functionality

- Product Type

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

- Product Features

- Colorless, transparent, with excellent gloss.

- Suitable for a wide range of ph exposure, ranging from strongly acidic or mildly alkaline environments (ph 0-10).

- Excellent resistance to hydrochloric acid, sulfuric acid, and salt water.

- Low water uptake.

- Compatible with commercial top coats.

- Product Highlights

- Abrasion: Excellent resistance to abrasion and mechanical damage.

- Adhesion: Excellent on degreased and corrosion free surfaces, including steel, aluminum, galvanized steel, mg-alloys, and stainless steel.

- Chemical resistance: Excellent resistance to aqueous salt solutions and a wide range of industrial chemicals.

Applications & Uses

- Markets

- Applications

- Application Area

- Application Method

- Compatible Substrates & Surfaces

- Applications

- Preferred Surface Preparation: SSPC-SP5 / NACE 1 white metal blast cleaning; WJ-1, SC-1 water jet cleaning.

- Coating: Can be deposited by spray, dip, and rod methods. Single component.

- Curing: Coating can be cured to final properties within minutes with appropriate UV exposure.

Properties

- Color

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Curing Time | max. 5 | minutes | — |

| Solid Content | 100.0 | Wt% | — |

| Viscosity (Brookfield cone/plate) | 140 - 150 (25) | cP (°C) | — |

| Specific Gravity | 1.1 | — | — |

| Film Thickness | 10 - 150+ | µm | — |

| Coverage | 780.0 | m2/kg/µm | — |

Technical Details & Test Data

- Coating Performance Data

Property Value Abrasion Resistance

(ASTM 4060)6.5 mg/1000 cycles

2 µm/1000 cycles

(Taber 5135, 1 kg, CS-10)Pull-off Adhesion

(ASTM D4541)18-20+ MPa (steel, Al, stainless) Impact Resistance

(ASTM D2794)21 ga CRS: 50 kg-cm

22 ga EGS: 37.5 kg-cm% Elongation

(ASTM D522)10% - Conical Mandrel Hardness

(ISO 14577-1)

(ASTM D3363)16.5-17.5 (microVickers)

140-150 MPa (Martens)

6H (Pencil)Accelerated

Corrosion Resistance

(SAE J2334)

(ASTM B117)CRS, Al-5052, EGS, ZnP

160 cycl. SAE J2334

1000hr salt spray scribe creep

(ASTM B117): 10mm on EGS,

13mm of Al-5052Corrosion Resistance

(Acid Bubble Test)>250 hr/µm - 1M H2SO4

>250 hr/µm - 1M HClThermal Cycling Pass 100 cycl. -50°C – 125°C Dielectric Breakdown

Strength (AC- 60Hz)120 V/µm @ 20°C

DBV > 3.5kV @ 25 µm thicknessSolvent Resistance

100 double rubs

(ASTM D5402)Pass - MEK, Toluene, Diesel fuel,

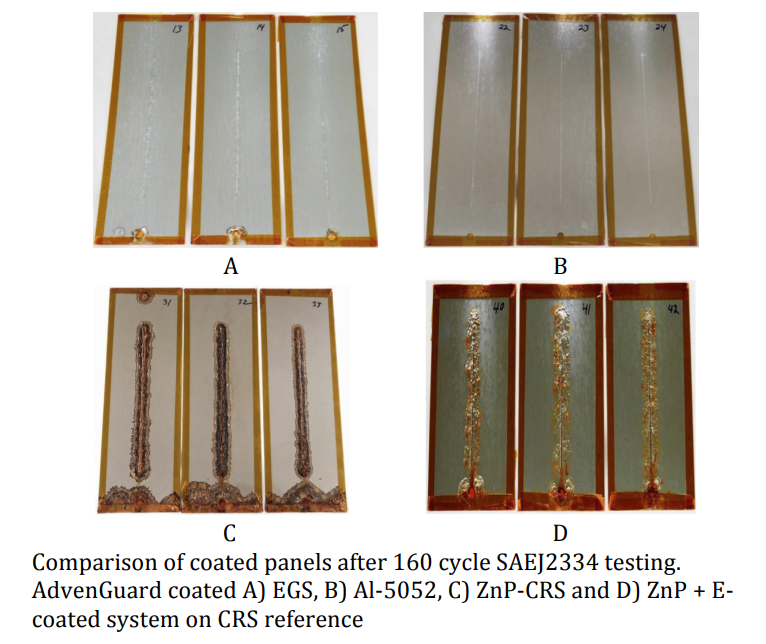

Butyl acetate, Hexane, Windex- AdvenGuard™ coated panels, 160 cycles SAEJ2334 testing

Substrate Rust/Blisters

(ASTM D610/D714)Max scribe

creep (mm)

(ASTM D1654)Cold-rolled steel (CRS) 44844 - Electro-galvanized steel (EGS) 44844 2.04 Aluminum-5052 44844 2.16 ZnP coated CRS 44844 23.87 Reference:

B958 P90 Zn Phosphate +

U32AD800 E-coat (on CRS)44844 18.33

Storage & Handling

- Shelf Life (unopened, refrigerated)

- 6+ months