Knowde Enhanced TDS

Identification & Functionality

- Product Type

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

- Product Features

- Colorless, transparent, with excellent gloss.

- Suitable for a wide range of pH (pH 0-10).

- Excellent resistance to hydrochloric acid, sulfuric acid, and salt water.

- Can be applied over ITO, SiO2 and other coatings.

- Product Highlights

- Abrasion: Excellent resistance to abrasion and mechanical damage. Taber abrasion superior to stainless steel, electroless-Ni, Type III anodization, and many commercially available hardcoats for polycarbonate.

- Adhesion: Excellent on degreased, corrosion-free, and activated glass, Al, and polycarbonate.

- Chemical Resistance: The fully cured coating offers excellent resistance to aqueous solutions and industrial chemicals.

Applications & Uses

- Markets

- Applications

- Application Area

- Compatible Substrates & Surfaces

- Curing Time

<10 min possible with high thermal budget substrates.

Typical curing time for single layer coatings on glass and aluminum. Actual curing times may vary depending on application and equipment specifications.

Substrate Temp Cure Time (min) °C Convection SW-IR 110 900 180 135 600 60 150 180 30 180 20 10

Properties

- Color

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Solid Content | 60.0 | Wt% | — |

| Viscosity (Brookfield cone/plate) (typical) | 10 (25) | cP (°C) | — |

| pH | Acidic | — | — |

| Specific Gravity | 1.07 | — | — |

| Typical Thickness | 2 - 3 | µm | — |

| Total Thickness (with multiple coatings; max thickness is substrate and temp. dependent) | max. 15 | mm | — |

| Coverage | 80.0 | m2/kg/µm | — |

Technical Details & Test Data

- Performance Data

Property Value Optical Properties TL improved for coated glass

and polycarbonate

Haze < 0.2% (10 μm coating)Surface Abrasion

Resistance

(ASTM D1044)ΔHaze <2% (1000 cycles)

(Taber 5135, 500 g, CS-10F)Abrasion Resistance

(ASTM 4060)1.4 mg/1000 cycles

0.15 µm/1000 cycles

(Taber 5135, 1 kg, CS-10)Hardness

(ISO 14577-1)

(ASTM D3363)8-9H (Pencil) on glass/metal

3-5H (Pencil) on plastics

100-115 (MicroVickers)

375-425 MPa (Martens)Cross-hatch Adhesion

(ASTM D3359)4-5B Corrosion Resistance

(Acid Bubble Test)>250 hr/µm - 1M HCl

(continuous exposure)Thermal Cycling Pass 100 cycl. 25°C – 125°C

Chemical Resistance

100 double rubs

(ASTM D5402)Pass - MEK, Toluene,

Methanol, Butyl acetate,

Hexane, Windex, 1M HCl, 1M

H2SO4, 1M KOHDielectric Breakdown

Strength140 V/µm @ 20°C

DBV ≈ 3kV @ 20 µm

thickness- Selected ANSI 61 Compliant Water Extraction Test Data

Parameters Amount Unit Heavy Metals (HMS):

Zn – US EPA limit is 5 mg/L0.023 mg/L Other HMS: As, Ba, Be, Cd, Cr, Co, Cu, Pb, Mo, Ni, Se, Ag,

Tl, V, HgND mg/L Halogenated compounds

(chloroform etc.)ND μg/L Phthalates ND μg/L Toxic solvents (benzene, pyridine etc.) ND μg/L Gasoline, diesel, motor oil ND mg/L

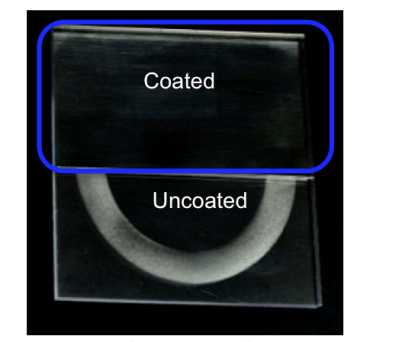

Abrasion comparison: AdvenShield coated and uncoated polycarbonate after ASTM D1044 test.