Knowde Enhanced TDS

Identification & Functionality

- Product Type

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

- Product Features

- Colorless, transparent, with excellent gloss.

- Suitable for a wide range of pH exposure (pH 0- 10).

- Excellent resistance to hydrochloric acid, sulfuric acid, and salt water.

- Epoxy functionality provides compatibility with many topcoat formulations.

- Two variants: One has enhanced abrasion resistance (2x lower ΔHaze) and one has enhanced corrosion resistance (20+% better) relative to each other.

- Product Highlights

- Abrasion: Excellent resistance to abrasion and mechanical damage. Taber abrasion superior to stainless steel, electroless-Ni, Type III anodization.

- Adhesion: Excellent on correctly degreased and corrosion free surfaces.

- Chemical Resistance: The fully cured coating offers excellent resistance to aqueous solutions and industrial chemicals.

- Temperature resistance: Dry service temperature range up to 150°C.

Applications & Uses

- Markets

- Applications

- Application Area

- Compatible Substrates & Surfaces

Properties

- Color

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Curing Time | 0.5 - 1 | hour | — |

| Solid Content | 60.0 | Wt% | — |

| Viscosity (Brookfield cone/plate) | 9 (25) | cP (°C) | — |

| pH | Acidic | — | — |

| Specific Gravity | 1.07 | — | — |

| Film Thickness | 1 - 20 | µm | — |

| Coverage | 80.0 | m2/kg/µm | — |

Technical Details & Test Data

- Performance Data

Property Value Abrasion Resistance

(ASTM 4060)

(ASTM D1044)1.4 mg/1000 cycles

0.15 µm/1000 cycles

(Taber 5135, 1 kg, CS-10)

ΔHaze <2% (1000 cycles)

(Taber 5135, 500 g, CS-10F)Pull-off Adhesion

(ASTM D4541)18-20+ MPa (Al, Stainless)

Hardness

(ISO 14577-1)

(ASTM D3363)100-115 (Vickers)

400-450 MPa (Martens)

8-9H (Pencil)Accelerated

Corrosion ResistanceAl - Pass 72 cycl. GMW15282

Corrosion Resistance

(Acid Bubble Test)>250 hr/µm - 1M HCl

Thermal Cycling Pass 100 cycl. 25°C - 125°C

Dielectric Breakdown

Strength140 V/µm @ 20°C

DBV ≈ 3kV @ 20 µm thickness- Selected ANSI 61 Water Extraction Test Data

Parameters Amount Unit Heavy Metals (HMS): Zn – US EPA limit is 5 mg/L 0.023 mg/L Other HMS: As, Ba, Be, Cd, Cr, Co, Cu, Pb, Mo, Ni, Se,

Ag, Tl, V, HgND mg/L Halogenated compounds

(chloroform etc.)ND μg/L Phthalates ND μg/L Toxic solvents (benzene, pyridine etc.) ND μg/L Gasoline, diesel, motor oil ND mg/L

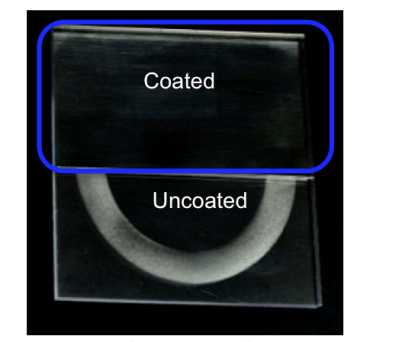

Abrasion comparison between ClearCorr coated and uncoated polycarbonate after ASTM D1044 test.

Storage & Handling

- Shelf Life (unopened, refrigerated)

- 1 months