Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Polymer Name

- Plastics & Elastomers Functions

- Technologies

Features & Benefits

- Materials Features

- Mechanical Properties

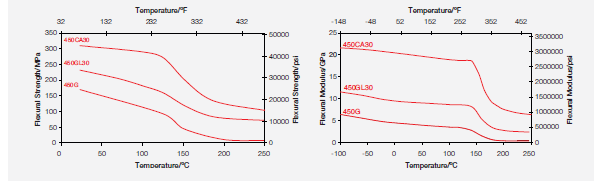

- Excellent high temperature mechanical properties

- High levels of strength and stiffness at very high temperatures

- Flexural modulus of 5 GPa and flexural strength of 100 MPa at 250°C for AF804

Applications & Uses

- Applications

- Plastics & Elastomers End Uses

- Applications

- Logging tools

- Seals and backup rings

- Connectors

- Compressor components

- Pumps (surface and submersible)

- Plugs and packers

- Composites

- Cables and wireline

- Tubes and pipes

- Insulating components

- Chemical Resistance

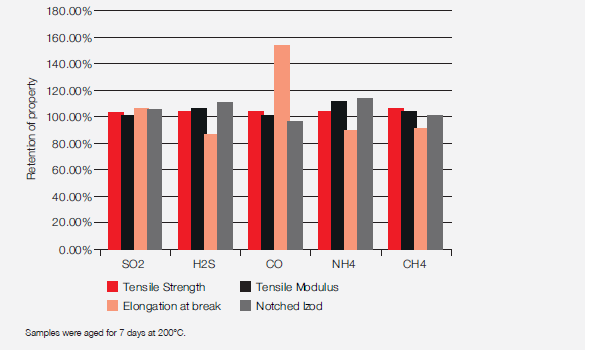

- Excellent chemical resistance to hydrocarbons, bases, acids, organic and inorganic reagents even at high temperatures

- AF800 PEEK materials are not subject to explosive decompression following high pressure exposure to oil field gasses

- Exceptional hydrolysis resistance. AF800 PEEK components retain a high level of mechanical properties when continuously conditioned in water or brine at elevated temperatures and pressures

- Wear Resistance

- Excellent friction and wear properties

- Specially formulated tribological grades which exhibit outstanding wear resistance over wide ranges of pressure, velocity, temperature and counterface roughness

- Excellent resistance to abrasion in sand slurry environments

Properties

- Physical Properties

- Electrical Properties

| Value | Units | Test Method / Conditions | |

| Tensile strength | 100.0 | MPa | ISO 527 |

| Elongation at break | 100.0 | % | ISO 527 |

| Secant modulus | 3.6 | GPa | ISO 527 |

| Flexural strength | 131.0 | MPa | ISO 178 |

| Flexural modulus | 3.9 | GPa | ISO 178 |

| Izod impact strength (notched) | 6.4 | kJ/m2 | ISO 180 |

| Hardness (Rockwell) | 126.0 | R | ASTM D785 |

| Thermal expansion | 4.7 | 10-5/°C | ASTM D696 |

| Limiting oxygen index | 35.0 | % | — |

| Density | 1.32 | g/cm3 | ISO 1183 |

| HDT | 152.0 | °C | ISO |

| RTI | 260.0 | °C | UL 746B |

| Glass transition | 143.0 | °C | DSC |

| Melting point | 343.0 | °C | DSC |

| Value | Units | Test Method / Conditions | |

| Dielectric strength (50 μm film) | 190.0 | kV/mm | — |

| Comparative tracking index | 150.0 | V | — |

| Excellent electrical insulation properties | min. 200 | °C | — |

Technical Details & Test Data

- Resistance