Knowde Enhanced TDS

Identification & Functionality

- Enzyme Type

- Ingredient Name

- Food Ingredients Functions

- Ingredients

- Pectinase

- Technologies

Features & Benefits

- Food Ingredients Features

Applications & Uses

- Markets

- Applications

- Food & Nutrition Applications

- Utilization

Ailazyme® BE, with an activity of 650 PLU/g, is very well suited for having a fast pectin degradation in berry pulp and juice. The enzyme is working excellently at low pH, up from pH 2 and at high temperatures (up to 60°C). Ailazyme® BE is suitable for the treatment of all types of berries and the product is easy to use. After dilution (10-20 times) in cold tap water, it can be added into the juice directly or into the pulp with a metering pump. Stir properly to evenly distribute the enzyme.

Application @ 50 °C; 1-2 h Pulp @ 11°Bx; Juice @ 18°Bx; Blackcurrant 125 – 200 ml/t 25 – 35 ml/1000 l Raspberry 85 – 125 ml/t 12 – 25 ml/1000 l Cranberry 125 – 175 ml/t 15 – 25 ml/1000 l Blueberry 40 – 65 ml/t 15 – 25 ml/1000 l - Fruit Processing Application

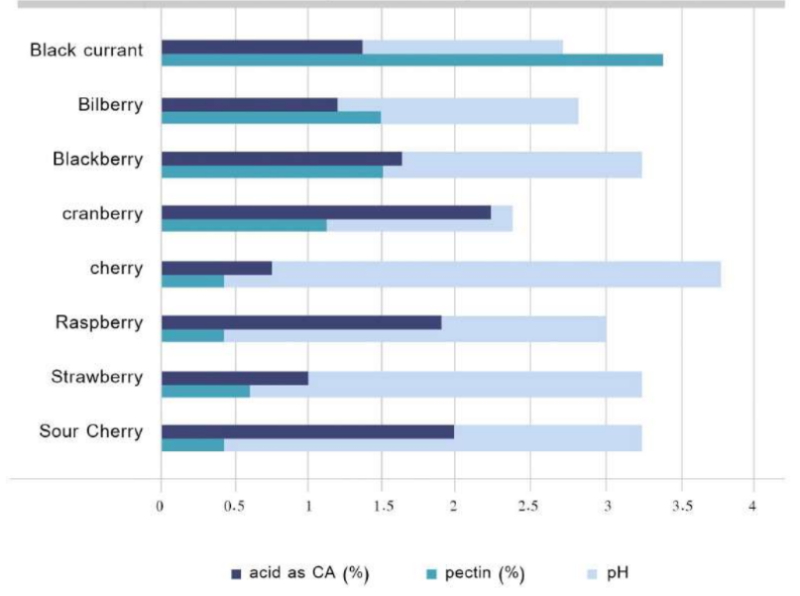

Thick skins and high quantities of soluble pectin, hemicellulose, polyphenols, and acidity are common characteristics of berry fruits like black currants and cranberries.

It's critical to choose the correct enzyme for mash treatment, as this is an essential stage that reduces mash viscosity quickly and delivers excellent juice yields, as well as color extraction and conservation. The juice's composition and subsequent processability, including ultrafiltration, are determined by the mash treatment. Total pectin degradation and appropriate juice clarity are ensured by the following juice treatment.

The chosen berry-processing enzyme is Ailazyme® BE. It's typically done in two stages: mash treatment and juice therapy.

Ailazyme® BE can be used on a wide range of berries. Its dosage is determined by the makeup of the berry fruit, such as pectin concentration and acidity.

Regulatory & Compliance

- Certifications & Compliance

- Purity and Regulatory Aspects

The enzyme in Ailazyme® BE is manufactured to comply with current purity specifications of JECFA (FAO/WHO) and conforms to FCC´s recommended specifications for food enzymes. These specifications also encompass heavy metals and the microbiological characteristics. Ailazyme® BE is a preservative free product in which the enzyme protein is stabilized with glycerol.

Packaging & Availability

- Packaging Type

- Packaging Information

Ailazyme® BE is available in 25 kg polyethylene drums and 1000 kg IBC’s

Storage & Handling

- Storage Information

Ailazyme® BE is best stored in the original packaging at 4–8°C in order to retain maximum activity during storage.