Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Industrial Additives Functions

- Technologies

Features & Benefits

- Labeling Claims

- Industrial Additives Features

- Features

No Chlorinated Solvents

The absence of chlorinated solvents in the manufacturing of Aldex C-800 UPS results in very low TOC leakage.

Very low color, taste or odor

Aldex C-800 UPS meets the requirements for paragraph 173.25 of the Food Additive Regulation of the U.S. Food and Drug Administration.

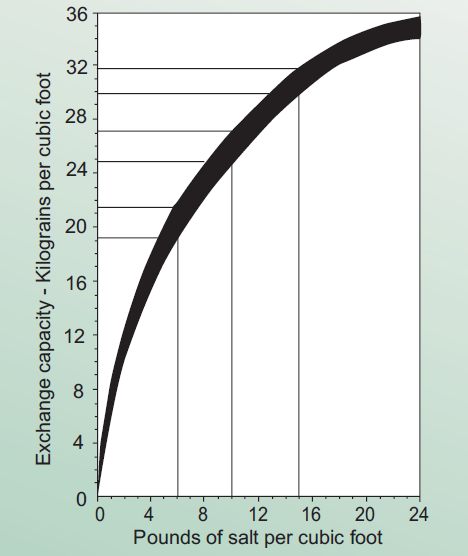

High Capacity

30,000 grains of softening capacity when regenerated with 15 lbs of NaCl per cubic foot and 20,000 grains with 6 lbs of NaCl per cubic foot ensuring high efficiency and low operating costs.

Long Life

Strong and durable beads ensure long service life.

Reliability

Aldex Chemical has over 40 years of field usage by thousands of customers demonstrate the reliability of Aldex ion exchange resins, zeolites and other water treatment media.

Applications & Uses

- Markets

- Applicable Processes

Properties

- Color

- Physico-Chemical Properties

| Value | Units | Test Method / Conditions | |

| Ionic Form (Shipped) | Sodium (Na+) | — | — |

| Moisture Content | 45 - 49.9 | % | — |

| Net Weight (as shipped) | 50.0 | lbs/cubic foot | — |

| Particle Size (Mesh - Less than 0.5% Through 50 Mesh) | 20 - 40 | — | — |

| Resin Composition | Sulfonated styrene / divinylbenzene copolymer | — | — |

| Specific Gravity | 1.28 | — | — |

| Total Capacity (41 Kilograins as CaCO3 per Cubic Foot) | min. 1.9 | meq/ml | — |

Regulatory & Compliance

- Certifications & Compliance

- Quality Standards

- Certification

Tested and Certified by WQA according to ANSI / NSF / CAN 44, 61, 372 and CSA B483.1 for materials safety only.

Technical Details & Test Data

- Recommended Operating Conditions

Influent pH: No restrictions Maximum Temperature: 250 °F Bed Depth: Minimum 24” Normal 36”Service Flow Rate: 1 to 5 US GPM per cubic footBackwash Flow Rate: See Fig. 2 Regenerant: Sodium Chloride (NaCl) or Potassium Chloride (KCl)Regenerant Strength: 5 to 15%, usually 10%Regenerant Flow Rate: 0.3 to 1.0 US GPM per cubic foot of resinRegenerant Contact Time: 15 to 60 minutesRegenerant Dosage Level: 2 to 15 lb per cubic footSlow Rinse (Displacement) Flow Rate: 0.3 to 1.0 US GPM per cubic foot of resinSlow Rinse Volume: 20 USG per cubic foot resinFast Rinse Rate: 1.0 to 5.0 US GPM per cubic foot resinFast Rinse Volume: 30 USG per cubic foot resin- Operating Suggestions

Iron

Aldex C-800 UPS will remove most of the dissolved iron, can filter much of the suspended iron and may or may not remove organically bound iron from water. When softeners are used to remove iron from the water, periodic cleaning of the bed mechanically or with a chemical iron cleaner may be necessary.

Chlorine

All cation exchange resins are affected by chlorine and suffer degradation and swelling. Is its recommended that the chlorine in the water be maintained below 1.0 ppm when using Aldex C-800 UPS.

Fig. 1 Exchange capacity vs. regeneration level Sodium form C-800 UPS Cation Resin

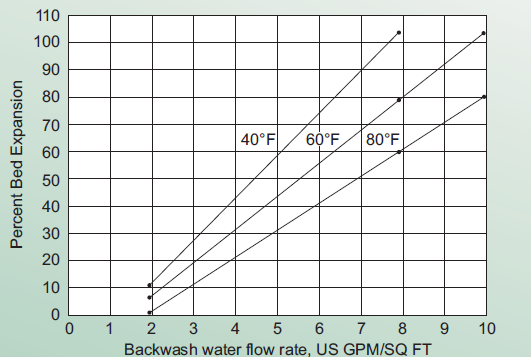

Backwash Characteristics

Aldex C-800 UPS should be backwashed for at least 10 minutes after each service cycle in a conventionally down flow regenerated softener. To reclassify the beads and remove suspended solids from the top of the bed, the resin bed should be expanded at least 50% according to Fig. 2. For non-conventional or upflow regenerated softeners, it may not be necessary to follow the above procedure since the backwash and brine injection are incorporated in the same step.

Fig. 2 Bed expansion vs. backwash flow rate for various water temperatures

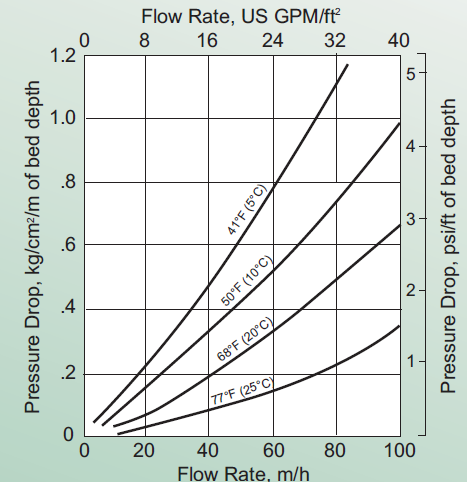

Pressure Drop

Figure 3 shows the expected pressure loss per foot of bed depth as a function of flow rate at various temperatures.

Fig. 3 Pressure Drop vs. Flow Rate

Safety & Health

- Safety Information

A material safety data sheet is available for Aldex C-800 UPS. Copies can be obtained from Aldex Chemical Co., LTD. Aldex C-800 UPS is not a hazardous product and is not WHMIS controlled.

Caution: Acidic and basic regenerant solutions are corrosive and should be handled in a manner that will prevent eye and skin contact. Before using strong oxidizing agents in contact with ion exchange resin, consult sources knowledgeable in the handling of these materials.

Packaging & Availability