Knowde Enhanced TDS

Identification & Functionality

- Base Oil Type

- Chemical Family

- Product Type

- Technologies

Features & Benefits

- Ready-to-Use Product Features

- Product Highlights

- Diamond Filled.

- Less than 40µ max particle diameter.

- Meets RoHS environmental standards.

- Screen print, stencil print dispensable.

- Super thermal conductivity.

- Electrical insulator.

- Features & Benefits

- Excellent thermal conductivity

- Non-electrically conductive

- Controlled silicone volatility

- No need for curing

- Heat flow away from electronic components canincrease reliability

- Non-toxic

- Non-corrosive

- Non-flammable

- Non-hazardous polymerization

Applications & Uses

- Markets

- Applications

- Application Area

- Application Method

- Potential Uses

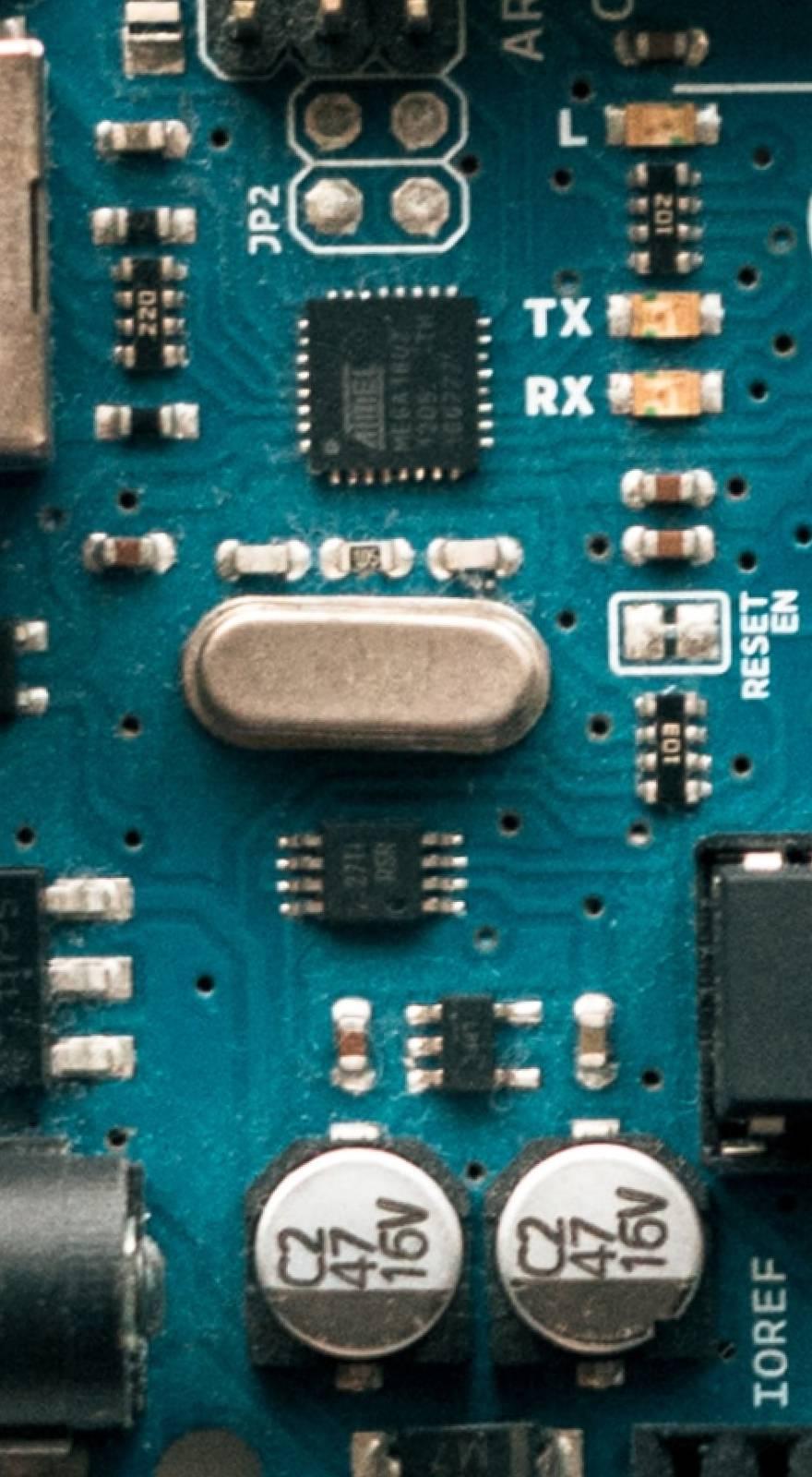

- CPUs for servers, notebook, and desktop computers

- Automotive temperature sensing devices

- GPUs (Graphics Chips)

- Temperature Sensors

- Northbridge Chipsets

- Custom ASICS Chips

- Effective thermal coupler for any heat sink device, CPU to heat sink

- Applied to the base and mounting studs of transistor, diodes and silicone controlled rectifiers

- Power transistors

- Diodes, semiconductors

- Thermal Joints

- For any device where efficient cooling is required

- Potting

- TEC Modules

- Hardware

- Telecommunications

- Right product for thermal management

- High-voltage corona suppressant in connectors for fly back transferors located in TV sets.

- Application Methods

Automated or manual dispensing for screen printing you may add a small amount of solvent to lower viscosity and allow for screen printing, evaporate solvent by allowing the screen printed surface to rest open faced for 10 minutes at room temperature.

- Usage Instructions

For industrial use only.

- Limitations

ULTRATHERM 500 is neither tested nor represented as suitable for medical or pharmaceutical use.

Properties

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Dielectric Constant (1kHz) | 5.35 | - | ASTM D150 |

| Dissipation Factor (1kHz, 25°C) | 0.006 | - | ASTM D150 |

| Evaporation (24 hrs, 200°C) | 0.5 | % | - |

| Evaporation (24 hrs, 25°C) | 0 | % | - |

| Specific Gravity (25°C) | 2.96 | - | - |

| Thermal Resistance (10 PSI) | 0.014 | °C -In²/W | - |

| Thermal Resistance (20 PSI) | 0.014 | °C -In²/W | - |

| Thermal Resistance (50 PSI) | 0.01 | °C -In²/W | - |

| Volume Resistivity | 1.98 x 10¹⁴ | ohm-cm | ASTM D257 |

| Viscosity | Paste | - | - |

| Average Particle Size | max. 40 | µ | - |

| Thermal Conductivity | 4.6 | W/m-K | - |

| Operating Temperature Range | -60 - 205 | °C | - |

| Thermal Impedance | 0.012 | °C -In²/W | - |

Regulatory & Compliance

- Certifications & Compliance

Safety & Health

- Environmental Impact Data

ODP None HCFC None VOC None HFC None

Packaging & Availability

- Availability & Packaging

1) Squeeze tubes * 0.5 oz --- 1 oz --- 2 oz --- 5.3 oz --- *Minimum of 12 tubes per order. 2) Syringes 2 gm --- 4 gm --- 6 gm --- 10 gm --- 3) Other Size Code Container Size A 2oz Jar B 5oz Tube C 8oz Jar D 1 pint Can E 10 lb. Can F 60 lb. Pail

Storage & Handling

- Storage Handling & Shelf Life

ULTRATHERM 500 has a shelf life of 5 years at room temperature (76°F) in an unopened container, settlings may occur during long term storage, it is recommended to re-mix the filler by hand or mechanical mixing. Keep container tightly closed store in cool area away from ignition sources and oxidizers, no special precautions need to be taken if product is handled according to directions. Shelf life is indicated on the product label, any special storage and handling instructions will be printed on the product container label.

- Clean Up and Disposal

ULTRATHERM 500 can be removed by using solvents such as mineral spirit, heptane, or isopropyl alcohol. Dispose of in accordance with local, state and federal regulations for hazardous waste.