Knowde Enhanced TDS

Identification & Functionality

- Reinforcement Material

- Composite Materials Functions

- Technologies

- Product Families

Features & Benefits

- Materials Features

- Key Advantages of HX5

Performance-Performance excels in the most extreme environments

- Thermally stable at extreme temperatures.

- Can be machined, primed, painted, and bonded.

- Scratch and abrasion-resistant.

- Satisfies spacecraft limits on outgassing and radiation resistance.

- 90% as strong as 6061-T6 aluminum.

- Low shrinkage and excellent dimensional stability (0.5% vs 2.0%).

- Extremely resistant to solvents, fuels, lubricants and chemicals including Skydrol and DEET.

- Galvanic Corrosion-resistant, unlike other metals.

- Meets flame, smoke, toxicity (FST) requirements for commercial aerospace and defense applications.

- Resistant to twisting, warping, and fatigue of molded structures in high thermal gradient environments.

- Passed accelerated lifetime thermal cycling and high-temperature thermal stability.

Weight-Half the weight of 6061-T6 aluminum components enables equipment to go faster and further

- Weight reduction with HX5 components results allows vehicles to go further and faster

Affordability-Decreases total lifecycle cost over machined aluminum components

- Reduces lead times

- Part count reduction

- Simplified supply chain

- Reduces sustainment cost

- Reduces production and labor costs

Production-Flexible production capabilities allowing the processing of thousands of parts per day

- Drop-in material for injection molding operations, extrusion, compression molding and thermoforming

- Compatible with metallic insert molding operations for multifunction products

- Delivery time reduced from weeks to days with injection molding

- No performance degradation at elevated loads

Design-High tolerance and dimensional stability for complex shapes

- Material flows exceptionally, allowing it to fill fine detail features without distortion

- Machines like aluminum without chipping, cracking, galling or gumming.

- Drills and threads like metal

- Unlike most solvent resistant materials, can be coated, primed, plated and adhesively bonded

- Can be metalized to meet EMI shielding requirements.

Applications & Uses

- Applications

- Composites End Use

- Composites Processing Methods

- Environmental Stability

Hx5 is Engineered To Survive

HX5 meets flame, smoke, toxicity (FST) requirements for commercial aerospace and defense applications, meeting the most stringent requirements for the Horizontal Burn Rate with no measurable toxic gasses being emitted.

Properties

- Thermal Properties

- Typical Properties

- Properties Of HX5

Mechanical Properties-HX5 Has 90% The Strength And 50% The Density Of 6061-T6 Aluminum.

- HX5 vs. Aluminum

The extreme mechanical performance of HX5 Was characterized by a broad range of standard ASTM tests important to aerospace, defense and space design engineers with a goal to replace 6061-T6 aluminum with a material of the same strength, yet half the weight.

- HX5 vs. Thermoplastics

HX5 also enables robust composite structures with best-in-class properties compared to other industry standard thermoplastics.

Thermal Properties-Hx5 is dimensionally stable at elevated temperatures.

- HX5 vs. Aluminum

HX5 thermal properties are important for stable structural designs in elevated temperatures. HX5 boasts a high Heat Deflection Temp (HDT) that is five times less than typical aerospace-grade aluminum, and a low Thermal Conductivity. The combination of these properties is ideally suited to greatly reduce twisting, warping, and fatigue of molded structures in high thermal gradient environments.

- Typical Mechanical Properties

Mechanical Properties ASTM -65ºF 73ºF 160ºF 250ºF 250ºF (Wet) Tensile Strength, (Ksi) D638 45.4 38.2 33.5 27 27.1 Tensile Modulus, (Ksi)

4,100 4,000 3,800 3,700 3,800 Poisson’s Ratio 0.347 0.397 0.4 0.407 - Compression Strength, (Ksi) D695 51 43 37 33 33 Compression Modulus, (Ksi)

1,270 1,240 1,150 1,020 1,200 Flexural Strength, (Ksi) D6272 54 53 48 42 - Flexural Modulus, (Ksi)

3,420 3,080 3,040 3,070 - Shear Strength, (Ksi) D5379 15 14 13 11 11 Bearing Strength, (Ksi) D5961 42 41 37 37 36 OHT Strength, (Ksi) D5766 19 18 18 18 17 OHC Strength, (Ksi) D6484 41 37 36 33 33 Notched Izod, Impact, (ft-lb/in) D256 0.945 0.589 - - - Density, (lb/ft^{3} ) D792 - 89 - - -

| Value | Units | Test Method / Conditions | |

| Glass Transition Temperature | 316.0 | ºF | D3418 |

| Heat Deflection Temperature | 500.0 | ºF | D648 |

| Spontaneous Ignition Temperature | 986.0 | ºF | D1929 |

| Horizontal Burn Rate (FST) | Meets horizontal burn rates | — | D635 |

| Optical Smoke Density Evaluation (FST, 1079 seconds, Flaming Exposure) | max. 130 | — | E662 |

| Toxicity (FST) | No measurable toxic gases (Only CO & CO2 emissions) | — | E800 |

| Thermal Conductivity (Heating) | 3.30 to 3.58 | BTU-in/hr-ft^{2} -ºF | E1530 |

| Coefficient of Thermal Expansion | 2.11×10^6 | L/L/ºF | E831 |

| Value | Units | Test Method / Conditions | |

| Injection Pressures | 12,000-18,000 | psi | — |

| Melt Temperature | 660-750 | ºF | — |

| Mold Temperature | 325-425 | ºF | — |

| Drying Conditions (300ºF) | 3.0 | hours | — |

| Moisture Content | 0.1 | % | — |

| Dew Point | -20.0 | ºF | — |

Technical Details & Test Data

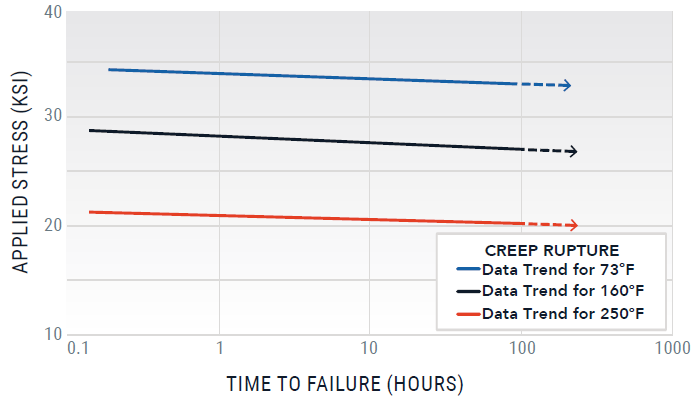

- Creep Rupture Trends

Creep Rupture, ASTM D 2990

Applied Load Versus Time to Failure Performed at Different Temperature

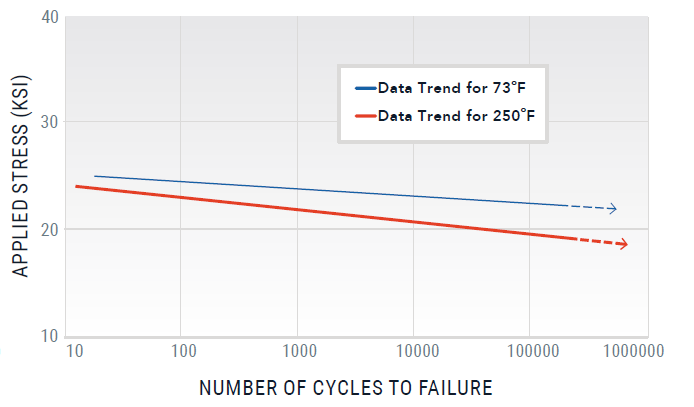

- Fatigue Performances Trends

Tensile - Tensile Fatigue

Applied stress Versus # of cycles to failure performed at different temperatures.

Packaging & Availability

- Prototyping Options

Alpine Advanced Materials can provide turnkey prototypes of your design in a wide variety of metallic and non-metallic materials, including HX5.

If you would like to machine your own prototypes, we have HX5 billets available for purchase.

Standard sizes include:

- 1/2” x 4”

- 1-3/4” x 3”

- 2″ diameter cylinder

Standard sizes are available in lengths of 6″ increments. Many other sizes available upon request.