Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Polymer Name

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Materials Features

- Features

- Exclusive use of Daikin AP231SH UHP PFA Semi -F57 approved resin.

- 100% virgin grade high performance resins used to resist stress cracking.

- Chemically inert to nearly all industrial chemicals and solvents.

- Highest thermal stability.

- Lowest permeation (even with aggressive chemicals such as HCL).

- Translucent.

- Smoothest surface finish resulting in less area of particle entrapment.

- Moisture absorption nearly zero.

- FDA compliant for food contact.

- Non-flammable.

- Suitable for use with flare or conventional fittings.

- Available in coiled hose and convoluted constructions.

- Superior resistance to common fluorosurfactants vs. other PFA and HP PFA.

- Greatest flex life values compared with other PFA and HP PFA materials.

Applications & Uses

- Applications

- Plastics & Elastomers End Uses

- Applications

- Semiconductor

- Chemical process

- Heat exchangers

- Laboratory applications

- Flow monitoring

- Pharmaceutical

Properties

- Flame Rating

- Physical Form

- Physical Properties

- Specifications

- General: Meets or exceeds the requirements listed in ASTM D 6867-03.

- Temperature: -320°F to 500°F.

- Flammability: UL 94 VO rated. UHP PFA resists combustion and does not promote flame spread.

| Value | Units | Test Method / Conditions | |

| Upper Service Temperature Long Term | 500.0 | °F | — |

| Specific Gravity | 2.15 | — | D 792 |

| Tensile Strength | 4500.0 | PSI | D 1708 |

| Elongation | 400.0 | % | D 638 |

| Flex Modulus | 90000.0 | PSI | D 790 |

| MIT Flex Life | 1750000.0 | — | D 2176 |

| Hardness | 60.0 | Shore D | D 2240 |

Regulatory & Compliance

- Certifications & Compliance

- Regulations

- FDA: UHP PFA is approved for use in food contact applications in compliance with FDA regulation: 21 CFR 177.1550.

- USP CLASS VI: ALTAFLUOR® meets the requirements of USP Class VI.

- NSF: ALTAFLUOR® 480 UHP PFA tubing is certified to NSF 51, NSF 61 and NSF 372.

- ALTAFLUOR® 480 UHP PFA has been tested and certified by WQA against NSF/ANSI 51, NSF/ANSI 61 to Commercial Hot (180° F/82° C), and NSF/ANSI 372 for lead free compliance.

Technical Details & Test Data

- Technical Details

ALTAFLUOR® 480 UHP PFA - Tubing

PART NUMBER

ID

OD

±

WALL

±

480-0125-030-OC 1/16 1/8 0.004 0.03 0.003 480-0250-030-OC 3/16 1/4 0.004 0.03 0.003 480-0250-040-OC 0.17 1/4 0.004 0.04 0.003 480-0250-047-OC 0.156 1/4 0.004 0.047 0.003 480-0250-062-OC 1/8 1/4 0.005 0.062 0.003 480-0375-062-OC 1/4 3/8 0.005 0.062 0.003 480-0500-062-OC 3/8 1/2 0.005 0.062 0.003 480-0750-062-OC 5/8 3/4 0.005 0.062 0.003 480-1000-062-OC 7/8 1 0.005 0.062 0.003 480-1250-075-OC 1.1 1.25 0.008 0.075 0.003 METRIC SIZES

480-0157-040-OC 2mm 4mm 0.005 1mm 0.003 0.078 0.157 0.005 0.04 0.003 480-0236-040-OC 4mm 6mm 0.005 1mm 0.003 0.157 0.236 0.005 0.04 0.003 480-0315-040-OC 6mm 8mm 0.005 1mm 0.003 0.236 0.315 0.005 0.04 0.003 480-0394-040-OC 8mm 10mm 0.005 1mm 0.003 0.315 0.394 0.005 0.04 0.003 480-0472-040-OC 10mm 12mm 0.005 1mm 0.003 0.394 0.472 0.005 0.04 0.003 Additional sizes up to 4” OD available upon request. Please contact Altaflo office for details. Available in natural color only. For pigmented items, see ALTAFLUOR® 400 series. Tested and meets requirements of Semi F-57 and Semi F-90. Test results available upon request.

ALTAFLUOR® 480 PFA - Bend Radius And Working Pressure Chart

PART NUMBER

0D

WALL

ID

BEND RADIUS

WORKING PRESSURE @ 73°F

480-0125-030-OC 0.125 0.03 0.062 1/2" 451 480-0250-030-OC 0.25 0.03 0.188 1" 226 480-0250-040-OC 0.25 0.04 0.17 1" 301 480-0250-047-OC 0.25 0.047 0.157 3/4" 353 480-0250-062-OC 0.25 0.062 0.125 1/2" 466 480-0375-062-OC 0.375 0.062 0.25 1" 311 480-0500-062-OC 0.5 0.062 0.375 2" 233 480-0750-062-OC 0.75 0.062 0.625 6" 155 480-1000-062-OC 1 0.062 0.875 22" 117 480-1250-075-OC 1.25 0.075 1.1 25” 75 METRIC SIZES 480-0236-040-OC 0.236 0.04 0.157 1-3/4" 313 6mm 1mm 4mm 480-0315-040-OC 0.315 0.04 0.236 2-1/2" 235 8mm 1mm 6mm 480-0394-040-OC 0.394 0.04 0.315 2-3/4" 188 10mm 1mm 8mm The above information is based on tests performed at 73° F and can vary in individual applications based on parameters such as temperature, chemical concentration, pressure, etc. Please consult factory for details. For an estimate on burst pressure at ambient temperature we consider a 3:1 ratio when exposure temperature is 73° F. However Altaflo does not recommend exceeding the suggested Working Pressure listed. Additional sizes up to 2” are available. Available in natural color only. For pigmented items, see ALTAFLUOR® 400 series.

ALTAFLUOR® 480 UHP PFA - Tubing Schedule 40 Pipe

PART NUMBER

NOMINAL SIZE

ACTUAL SIZE

WALL

STOCK LENGTH

480-0540-088-0C 1/4" .540" ± .010 .088"±.020,-0 10ft 480-0840-109-0C 1/2" .840" ± .010 .109"±.020,-0 10ft 480-1050-113-0C 3/4" 1.050" ± .010 .113"±.020,-0 10ft 480-1315-133-0C 1" 1.315" ± .010 .133"±.020,-0 10ft 480-1660-140-OC 1-1/4" 1.660" ± .015 .140"±.020,-0 10ft 480-1900-145-OC 1-1/2" 1.900" ± .015 .145"±.020,-0 10ft 480-2375-154-OC 2" 2.374" ± .015 .154"±.020,-0 10ft Additional sizes and Schedule 80 Pipe available upon request. Minimum order requirements for non-catalog items will apply. 10 ft minimum order requirement - can be cut into shorter lengths for shipment. All 480 UHP PFA in stock.

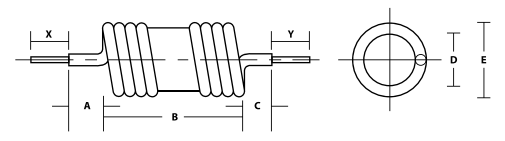

ALTAFLUOR® 480 UHP PFA - Standard Convoluted Construction

PART NUMBER

NOMINAL OD SIZE

ID MIN

ID MAX

OD MAX

NOMINAL WALL

CONVOLUTIONS PER INCH

48C-0375-020-0C* 3/8 0.251 0.275 0.375 0.02 6 48C-0500-023-0C* 1/2 0.364 0.375 0.5 0.023 6 48C-0625-025-0C* 5/8 0.485 0.5 0.625 0.025 5.5 48C-0750-025-0C* 3/4 0.608 0.625 0.75 0.025 5 48C-0875-025-0C* 7/8 0.73 0.75 0.875 0.025 4 48C-1000-025-0C* 1 0.86 0.875 1 0.025 3.5 *Custom item - please consult factory for lead time and minimum order requirements. Available in natural color only. For pigmented items, see ALTAFLUOR® 400 series.

ALTAFLUOR® 480 UHP PFA - Ultra Flex Convoluted Construction

PART NUMBER

NOMINAL OD SIZE

ID MIN

ID MAX

OD MAX

NOMINAL WALL

CONVOLUTIONS PER INCH

48U-0375-020-0C* 3/8 0.251 0.275 0.375 0.02 9 48U-0500-023-0C* 1/2 0.364 0.375 0.5 0.023 9 48U-0625-025-0C* 5/8 0.485 0.5 0.625 0.025 9 48U-0750-025-0C* 3/4 0.608 0.625 0.75 0.025 8 48U-0875-025-0C* 7/8 0.73 0.75 0.875 0.025 8 48U-1000-025-0C* 1 0.86 0.875 1 0.025 8 *Custom item - please consult factory for lead time and minimum order requirements. Available in natural color only. For pigmented items, see ALTAFLUOR® 400 series. The above information is based on tests performed at 73° F and can vary in individual applications based on parameters such as temperature, chemical concentration, pressure, etc. Please consult factory for details. NOTE: The values represented above are based on the use of 100% virgin grade high performance - low melt flow PFA resin as used in the production of ALTAFLUOR® 480 Series Tubing. When comparing data it is critical that performance values are listed for the grade of resin used.

- ALTAFLUOR® 480 UHP PFA - Coiled Hose

Custom item - see Coiled Hose Order Form for ordering information. Please consult factory for additional details.