Knowde Enhanced TDS

Identification & Functionality

- Animal Feed & Nutrition Functions

- Technologies

Features & Benefits

- Animal Feed & Nutrition Features

- Features & Benefits

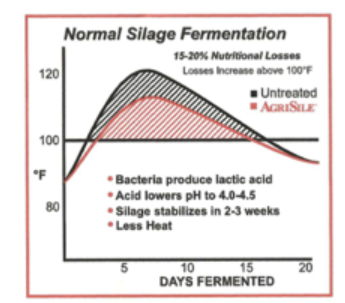

- Normal Silage Losses - Once silage is pit in a silo, a series of uncontrollable events take place. The natural fermentation process will preserve the silage, but not without some loss of dry matter, energy and digestible protein.

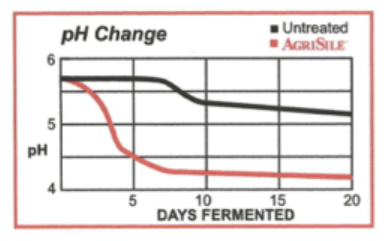

- AgriSile® Reduced Losses - Your dairy or beef ration is balanced to supplement your silage. As the nutritional value of your silage decreases, the need and expense of off-farm supplements increase. By adding AgriSile® you can begin to control some of those events that are normally uncontrollable. You can see from accompanying graphs that AgriSile® enhances fermentation and decreases nutritional losses.

- AgriSile® Speeds Fermentation - AgriSile® a more rapid drop in pH and this means better silage.

Lactic Acid Bacteria – The Engine That Powers Fermentation -Many outstanding universities such as Cornell and Michigan State have established the necessary criteria for a silage inoculant.

- A minimum of 100,000 cfu of lactic acid bacteria per gram of silage.

- Live bacteria – non-viable (dead) bacteria are no good.

- Always refrigerated during storage.

- Dissolves in water – better coverage than dry products.

- Can be used with injector systems.

- Two strains of homofermentative, lactic acid bacteria, each designed to work at different pH ranges.

- Special applicator – will not damage bacteria.

AgriSile® – The Leader in Silage Inoculants

- Freeze-dried and continually refrigerated during storage. Always 100% fresh, healthy, and alive.

- Provides more than 125,000 cfu of specific lactic acid bacteria per gram of silage. Not only enough bacteria to produce a good fermentation, but the right strains of bacteria to initiate a rapid pH drop.

- Bacterial strains that convert plant sugars to lactic acid and stabilize silage sooner.

- Limits mold and yeast growth because a quick drop to the range of pH 4.0 inhibits their reproduction and growth. This means better bunk life and feed values during feed out.

- Water-soluble for easy mixing and even application .

- Special equipment to safely apply AgriSile® without damaging the bacteria.

Applications & Uses

- Markets

- Management Guidelines For Good Silage

- Keep Knives sharp

- Chop 3/8 to ½

- Fill rapidly

- Ensile at proper moistures.

- Insure tight pack.

- Storage structure, side alls, floors and doors should be air and water tight.

- Exposed areas properly covered

- Add AgriSile® at recommended rates.

- Crop Maturity

- Corn silage Early to full dent

- Alfalfa 1/10 bloom

- Cereal silage Milk to soft dough

- Grasses When first sterns head out

- Clover ¼ to ½ bloom

- Forage sorghum Grain medium to hard dough

- or begin to lose color

Proper Moisture Range % BUNKER STAVE SEALED LENGTH OF CUT

65-70% 60-70% 50-55% 3/8"-1/2" - Mixing Instructions/Sprayer Calibration

- Dissolve 1 jar into 1/2 gallon of luke warm water. Shake or stir vigorously.

- Pour into sprayer.

150,000 cfu/gram (Recommended Treatment)

100g

SPRAYER TANK VOLUME (gal) 10 25 1 JAR- 100 TONS (0z/Ton) 13 32 2 JARS-200 TONS (0z/Ton) 6.4 16 5 JARS-500 TONS (oz/Ton) 2.6 6.4

250gSPRAYER TANK VOLUME (gal) 10 25 50 2 JAR-500 TONS (0z/Ton) 2.6 6.4 12.8 4 JARS-1000 TONS (oz/Ton) 1.3 3.2 6.4 6 JARS- 1500 TONS (0z/Ton) .X X 4.3

500gSPRAYER TANK VOLUME (gal) 10 25 50 1 JAR-500 TONS (oz/Ton) 2.5 6.3 12.6 2 JARS-1000 TONS (oz/Ton) 1.3 3.2 6.4 3 JARS-1500 TONS (oz/Ton) X X 4.2 100,000 cfu/gram (University recommended minimum)

100g

SPRAYER TANK VOLUME (gal) 10 25 1 JAR-150 TONS (oz/Ton) 8.6 21.4 2 JARS-300 TONS (oz/Ton) 4.3 10.7 5 JARS-750 TONS (oz/Ton) 1.7 4.3

250gSPRAYER TANK VOLUME (gal) 10 25 50 1 JAR-375 TONS (oZ/Ton) 3.4 8.6 17.1 2 JARS-750 TONS (oz/Ton) 1.7 4.3 8.5 500g

SPRAYER TANK VOLUME (gal) 10 25 50 1 JAR-750 TONS (oz/Ton) 1.7 4.3 8.5 2 JARS-1500 TONS (oz/Ton) X 2.2 4.3 Calibrate Sprayer Accordingly.

Packaging & Availability

- Packaging Type

- Availability

100 Gram Jar

- Treats 100 Tons

- Min. 1 box (10 Jars)

250 Gram Jar

- Treats 250 Tons

- Min. 1 box (10 Jars)

500 Gram Jar

- Treats 500 Tons

- Min. 1 box (10 Jars)

50 Lb. Bag

Storage & Handling

- Storage Conditions

- To achieve maximum shelf life, granular AgriSile® should be stored in a cool and dry place out of direct sunlight.

- AgriSile® concentrate should be kept in the refrigerator or freezer.