Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- CASE Ingredients Functions

- Technologies

- Product Families

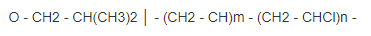

- Chemical Structure

Features & Benefits

- CASE Ingredients Features

- Product Characteristics

It is a good type of chlorinated binder. Can be used for anti-corrosive paints; printing inks, steel structure paints, wall paint, road-marking paints, buildings anti-fire paint, light metal coating, deck paints, watercraft & container paints, engineering paints for machine & automobile, concrete & asbestos cement, etc. They can be used as modifier in rubber & plastic industry as well.

Applications & Uses

- Applications

- Compatible Polymers & Resins

- Compatible Substrates & Surfaces

- Applications

- Binding vehicle for composite printing inks

- Anti-corrosion coatings

- Application and Guide

Binding vehicle for composite printing inks

As an excellent binding vehicle for composite printing inks, it is used in wide range of fields. CMP resin has the following advantages:

- Good solubility: Soluble in most of solvents, such as benzenes, acetones and esters commonly used in inks production, in addition, the dissolved solution has a higher degree of transparency.

- Excellent blending property: Easily blended with other ink binding vehicles to enhance its working performance, such as CPP, EVA and CEVA resins.

- High dispersivity: It has good dispersing and wetting properties to inks and dyes, ensuring the pigments fully display theprimary color and transferability.

- Superior adhesion: The polymer chains contain a large quantity of ether bonds, which have strong adhesive strength to BOPP, OPP, PET and other plastic film.

- Good stability: There is no reactive double bonds, no saponifiable ester bonds in the resin, and the chlorine atoms in the molecular link are very stable. These offer ink layers strong resistance to heat, light, weathering, yellowing and chalking.

Anti-corrosion coatings

It is widely used in the fields of anti-corrosion coatings:

- Industrial anti-corrosion coatings, such as factory buildings, equipment, pipeline, tanks, municipal engineering, piers and harbors, etc.

- Marine coatings, applicable to the various parts of the hull, resisting sun exposure and seawater erosion.

- Transport paints, such as containers, transport machinery, dangerous chemicals tankers.

- Light metals primer, top paint, such as garage doors and windows, roof rain sinks, balcony, lampposts and road crash barriers.

- Large-scale key projects, such as bridge, ocean and energy engineering.

Properties

- Specifications

| Value | Units | Test Method / Conditions | |

| Viscosity | 15±5 | mpa.s | — |

| K Value (Fikentscher) | ca. 35 | — | — |

| Chlorine Content | 44 ±1 | % | — |

| Density | min. 0.30 | g/ml | — |

| Volatile Matter | max. 0.50 | % | — |

Safety & Health

- Precautions

During operation the operators must wear self-inhalation filter type dust masks, away from fire, heat. Smoking is strictly prohibited at workplace. Apply good ventilation system and equipment to avoid dust and contact with oxidants. Handle with care.

Packaging & Availability

- Packaging Type

- Packaging

- 20kgs/bag, 600kgs/pallet

- 12000kgs/1x20'GP with pallet

- 14000kgs /1x20'gp without pallet

Storage & Handling

- Storage

CMP resin is liable to suffer from agglomeration due to its own glass transition temperature

under high pressure & temperature, exposure, moisture and other harsh storage or transportation circumstances.

Therefore, keep sealed, avoid stress, keep away from heat source and humid environment during transportation. Store in a cool, dry and well-ventilated place. Guard against moisture, sunlight and high temperature.