Knowde Enhanced TDS

Identification & Functionality

- Product Type

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Ready-to-Use Product Features

- Non-Silicone Advantages

Silicone-based compounds have an undesirable tendency to physically migrate and contaminate components nearby. This interferes with circuit operation long after hardware installation to cause unexpected, untimely and often inaccessible problems. The AOS Heat Sink Compound’s no creep feature extends circuit life by protecting components longer and by eliminating premature failure of adjacent components caused by migrating silicone base fluid.

- Features and Benefits

AOS 340 LR is non-silicone based, non-reactive, and non-abrasive with a soft, grease-like consistency with thixotropic behavior. It has excellent dielectric properties, lowest thermal resistance and superior durability (will not pump-out).

Applications & Uses

- Markets

- Applications

- Application Area

- Major Applications

AOS 340 LR is designed to be applied where thermal coupling is required and where a device may need to be removed from the heat sink at a later time. Major applications include CPU/GPU, power semiconductors and LED’s. It is also the most efficient and cost effective low bond line TIM 2 for use in any thermal management application.

- Performance

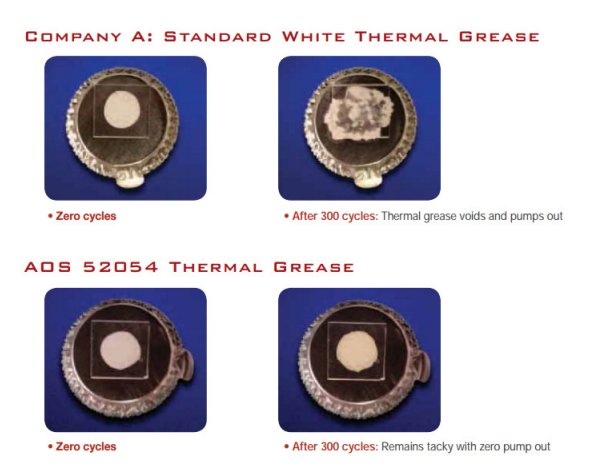

AOS 340 LR’s exceptional performance can be attributed to its durability and resistance to pump-out. AOS 340 LR was uniquely engineered and tested under thermal cycling conditions in order to ensure stability. Due to the growing number of various applications in the thermal management industry, an increased demand for longer lasting products has proven essential. AOS 340 LR’s resistance to pump-out provides excellent performance and product longevity.

Properties

- Color

- Physical Form

- Appearance

- Smoot White Paste

- Operating Temperature Range

- -40 to 180

- Typical Properties

- Electrical Properties

| Value | Units | Test Method / Conditions | |

| Anticipated Bond Line Thickness (Based on filler dimensions) | max. 0.3 | mils | - |

| Bleed (200°C, 24 Hrs, %/Wt) | 0.0 | % | ASTM 6814 |

| Evaporation (200°C, 24 Hrs, %/Wt.) | 1.0 | % | FTM-321 MODIFIED |

| Flow Rate (30cc Syringe, 0.08”orifice at 50 PSI, 25°C) | 7 - 10 | g/min | - |

| Specific Gravity (25°C) | 3.0 | - | ASTM D-70 |

| Thermal Conductivity (36°C) | 1.3 | W/m-K | ASTMD 5470-17 |

| Thermal Resistance (50°C) | 0.031 | °C/W | Oracle TTV Model 270-7806-01 |

| Viscosity (1 sec-1 , 25°C) | 470000.0 | cP | Rheometer |

| Viscosity (1 sec-1 , 50°C) | 410000.0 | cP | - |

| Value | Units | Test Method / Conditions | |

| Dielectric Constant (25°C, 1,000 Hz) | 5.02 | - | ASTM D-150 |

| Dielectric Strength (after exposure to 85°C, 85% R.H. for 48 hours) | 212.0 | - | - |

| Dielectric Strength (0.05” gap) | 265.0 | V/mil | ASTM D-149 |

| Dissipation Factor (25°C, 1,000 Hz) | 0.0022 | - | ASTM D-150 |

| Volume Resistivity | 2 x 10¹⁵ | ohm-cm | ASTM D-257 |

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- Thermogravimetric Analysis (TGA)

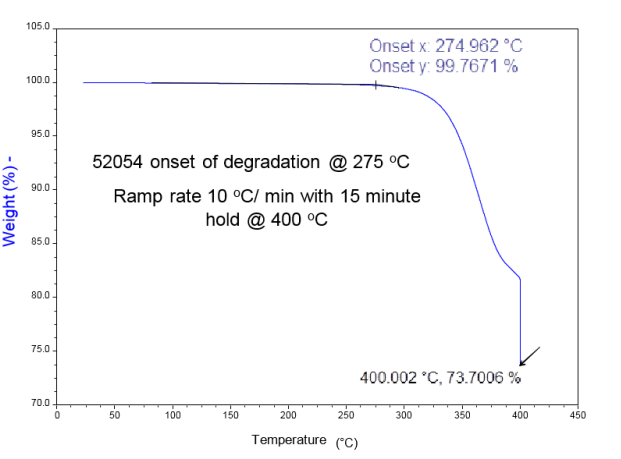

Thermogravimetric Analysis is a vital technique used in evaluating the thermal stability of a material over a designated temperature range. A material will begin to lose weight % composition at the onset temperature of degradation. AOS 340 LR’s highly stable thermal properties allow it to reach temperatures as high as 275°C in an inert atmosphere before any initial degradation or mass loss reinforcing its performance and durability.

Thermogravimetric Analysis of AOS 340 LR - 52054

- Test Results