Knowde Enhanced TDS

Identification & Functionality

- Product Type

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Ready-to-Use Product Features

- Tribological Effect

- Friction and wear reduction.

- Stick-slip reduction.

- Seizure prevention.

- Micropitting reduction.

- Corrosion protection.

- Beneficial Characteristics

ANS Tricolit® is a series of thermoset surface coatings serving to reduce friction and wear. Tricolit coatings can be applied by spraying, dipping or brushing and are suitable for treatment of non-ferrous materials which cannot be triboconditioned. The coating gives the component great tribological performance at a competitive price. Some beneficial characteristics are:

- Cured film thickness from 5 to 100 um.

- Water-based formulations = zero VOC emissions.

- Work both in dry and lubricated contacts.

Applications & Uses

- Applications

- Application Method

- Cure Method

- Application Areas

ANS Tricolit® coatings are used for improving tribological properties of various parts (e.g. guide bars, rails, slideways) in those cases where use of Triboconditioning® is not feasible (e.g. because of complex geometry, chemical incompatibility, inappropriate mechanical properties). The coatings are also suitable for servicing of parts which have already been in use.

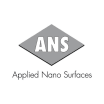

- How It Is Done

ANS Tricolit® is applied to the surface like a regular paint and heat-cured afterwards. The resulting coating comprises a balanced set of friction modifiers, such as WS2, BN, PTFE, and graphite, embedded in a cross-linked organic polymer matrix.

- Substrate

- Steel

- Bronze

- Aluminum

- Glass

Properties

- Color

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Curing (250°C) | 60 | minutes | — |

| Coating Thickness | 10 - 25 | µm | — |

| Load Capacity | max. 10 | MPa | — |

| Operating Temperature | max. 200 | °C | — |

Technical Details & Test Data

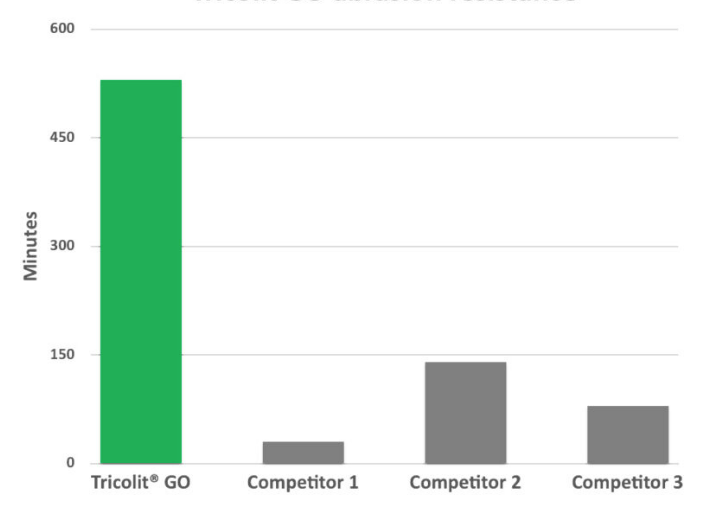

- Tricolit GO Abrasion Resistance

Packaging & Availability

- Packaging Type