Knowde Enhanced TDS

Identification & Functionality

- Chemical Name

- Pharma & Nutraceuticals Functions

- CAS No.

- 10039-26-6

- Technologies

Features & Benefits

- Key Benefits

- Compressibility

- Blending properties

- Storage stability

Applications & Uses

- Markets

- Dosage Form

- Manufacturing Technology

- Applications

- Wet granulation

- Dry granulation

- Blends Premixes /Triturations

- Fermentation processes

Properties

- Appearance

- White crystalline powder

- Soluble in

- Water

- Insoluble in

- Ethanol (96%)

- Specifications

| Value | Units | Test Method / Conditions | |

| Absorbance (Proteins and Light Absorbing Impurities, [A] 1%, 1 cm at 210 to 220 nm) | max. 0.25 | — | — |

| Absorbance (Proteins and Light Absorbing Impurities, [A] 1%, 1 cm at 270 to 300 nm) | max. 0.07 | — | — |

| Absorbance (Proteins and Light Absorbing Impurities, [A] 10%, 1 cm at 400 nm) | max. 0.04 | — | — |

| Acidity or Alkalinity (at ml 0.1 M NaOH) | max. 0.4 | — | — |

| Escherichia Coli | Negative | in 1g | — |

| Heavy Metals | max. 5 | ppm | USP |

| Loss on Drying | max. 0.5 | % | — |

| Particle Size Distribution (max. 100 µm) | min. 70 | % | Air Jet Sieve |

| Particle Size Distribution (max. 150 µm) | min. 85 | % | Air Jet Sieve |

| Particle Size Distribution (max. 315 µm) | min. 97 | % | Air Jet Sieve |

| Particle Size Distribution (max. 45 µm) | max. 50 | % | Air Jet Sieve |

| Residue on Ignition / Sulphated Ash | max. 0.1 | % | — |

| Salmonella | Negative | in 10g | — |

| Specific Optical Rotation (at [α] 20D, Anhydrous Substance) | 54.4 - 55.9 | degree | — |

| Total Aerobic Microbial Count | max. 100 | CFU/g | — |

| Total Yeast and Molds Count | max. 50 | CFU/g | — |

| Water Content | 4.5 - 5.5 | % | KF Method |

Regulatory & Compliance

- Certifications & Compliance

- Grade

- Residual Solvents

No class 1, 2, 3 solvents are used during production. (CPMP/ICH/283/95 + CVMP/VICH/502/99)

- Certifications

- EXCIPACT certified (GMP)

- ISO 9001 and ISO 22000 certified

- Following IPEC cGMP

- On-site Batch testing & Batch release

- Certified animal Rennet-free raw materials

Technical Details & Test Data

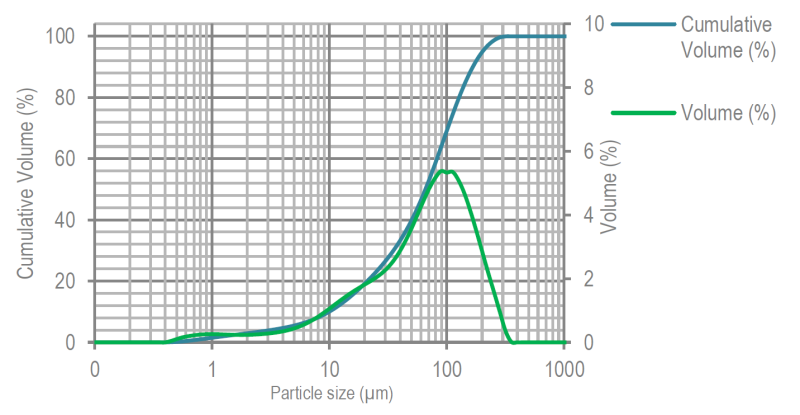

- Particle Size Distribution

PSD

(Air Jet Sieve)Specifications (%)

% < 45 µm ≤ 50 % < 100 µm ≥ 70 % < 150 µm ≥ 85 % < 315 µm ≥ 97 Due to the presence of milled particles, this α lactose monohydrate combines good compaction and blending properties.

PSD (Malvern Laser Diffraction, Indicative Values)

X10 : 10 µm, X50 : 66 µm, X90 : 166 µm

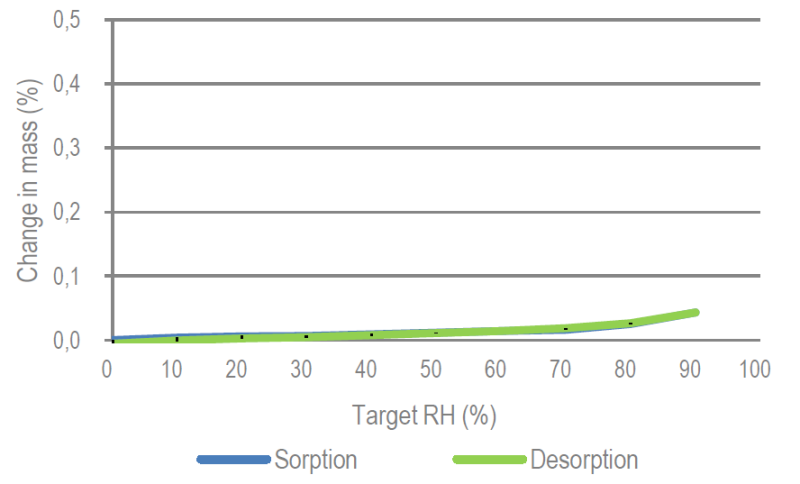

- Moisture Sorption

The hygroscopicity of α lactose monohydrate is very low which enables high stability both in storage as well as in formulations

DVS (Dynamic Vapor Sorption)

- Flowability

- Poured Density : 0.59 g/mL

- Tapped Density : 0.86 g/mL

- Carr’s Index : 31 %

- Hausner Ratio : 1.45

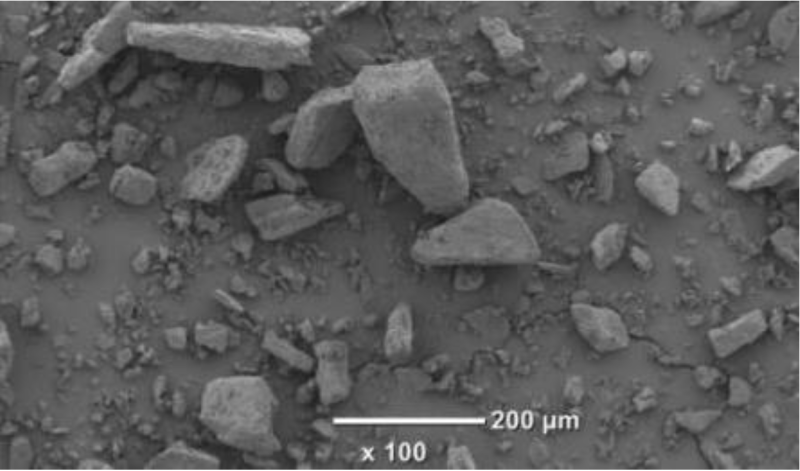

- Scanning Electron Microscopy

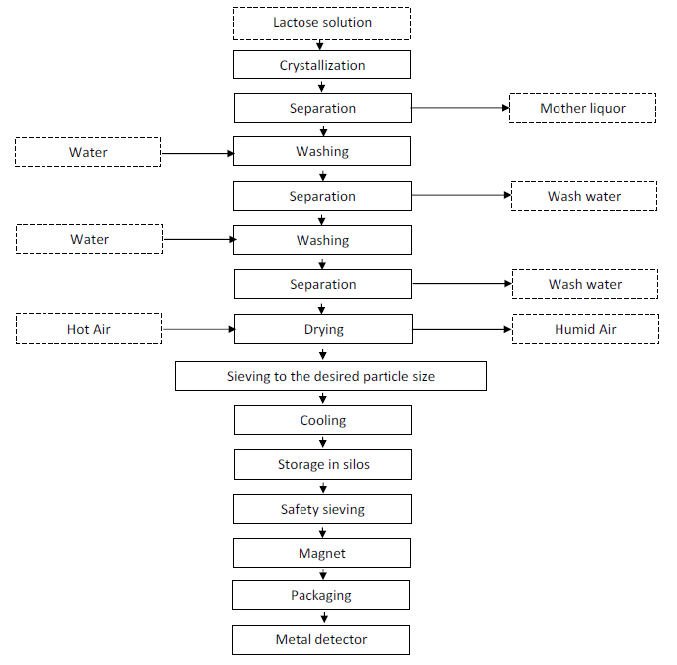

- Process Flow Chart

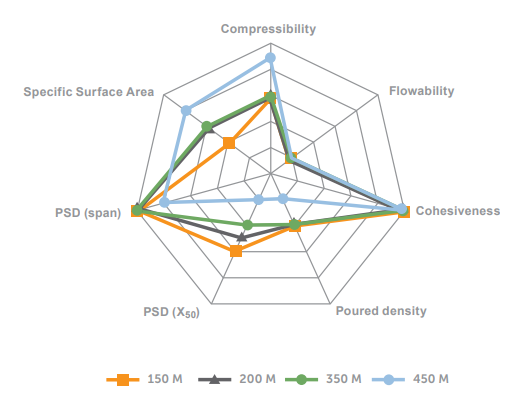

- Product Performance Characteristics

1 2 3 4 5 Compressibility Very low Low Good High Very high Flowability (Carr’s index) More than 26 21 to 25 16 to 20 11 to 15 0 to 10 Cohesiveness (Hausner ratio) 1.00 to 1.11 1.12 to 1.18 1.19 to 1.25 1.26 to 1.34 ≥ 1.35 Poured density (g/ml) Less than 0.50 0.50 to 0.59 0.60 to 0.69 0.70 to 0.79 ≥ 0.80 X50 0 to 20 21 to 50 51 to 100 101 to 200 ≥ 200 Span (PSD)* Less than 1.0 1.0 to 1.4 1.5 to 1.9 2 to 2.4 ≥ 2.5 SSA (m2/g) ≤ 0.10 0.10 to 0.40 0.41 to 0.80 0.81 to 1.40 ≥ 1.41 * Span = (X90 - X10) / X50

Packaging & Availability

- Packaging Type

Storage & Handling

- Shelf Life

- 36 Months

- Storage Information

Store in original unopened packaging, in a dry and odor free place.