Knowde Enhanced TDS

Identification & Functionality

- Chemical Name

- Pharma & Nutraceuticals Functions

- CAS No.

- 63-42-3

- EC No.

- 200-559-2

- Technologies

Features & Benefits

- Benefit Claims

- Key Benefits

- Very good compressibility

- Good flowability

- Storage stability

- Good blending properties

Applications & Uses

- Markets

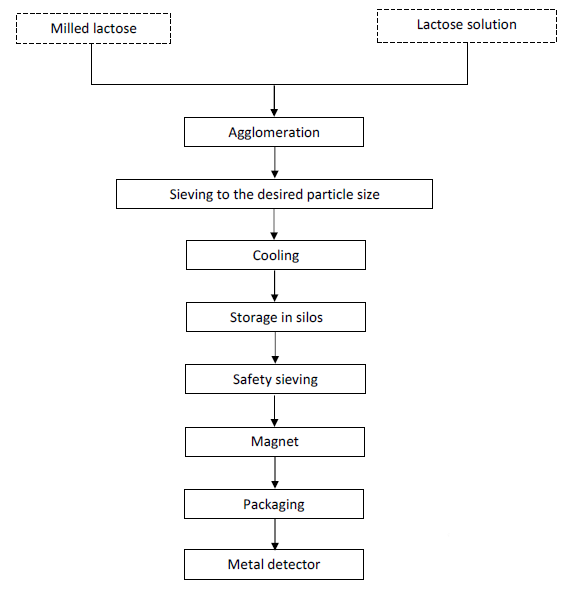

- Manufacturing Technology

- Applications

- Direct compression

- Tablets

- Effervescent tablets

- Sweetener tablets

- Hard capsules, sachets

- Direct compression

Properties

- Appearance

- White crystalline powder

- Soluble in

- Water

- Insoluble in

- Ethanol (96%)

- Specifications

| Value | Units | Test Method / Conditions | |

| Absorbance (Proteins and Light Absorbing Impurities, [A] 1%, 1 cm at 210 to 220 nm) | max. 0.25 | — | — |

| Absorbance (Proteins and Light Absorbing Impurities, [A] 1%, 1 cm at 270 to 300 nm) | max. 0.07 | — | — |

| Absorbance (Proteins and Light Absorbing Impurities, [A] 10%, 1 cm at 400 nm) | max. 0.04 | — | — |

| Acidity or Alkalinity (at ml 0.1 M NaOH) | max. 0.4 | — | — |

| Escherichia Coli | Negative | in 1g | — |

| Heavy Metals | max. 5 | ppm | USP |

| Loss on Drying | max. 0.5 | % | — |

| Particle Size Distribution (max. 150 µm) | 40 - 84 | % | Air Jet Sieve |

| Particle Size Distribution (max. 355 µm) | min. 90 | % | Air Jet Sieve |

| Particle Size Distribution (max. 500 µm) | min. 99 | % | Air Jet Sieve |

| Particle Size Distribution (max. 75 µm) | 10 - 36 | % | Air Jet Sieve |

| Residue on Ignition / Sulphated Ash | max. 0.1 | % | — |

| Salmonella | Negative | in 10g | — |

| Specific Optical Rotation (at [α] 20D, Anhydrous Substance) | 54.4 - 55.9 | degree | — |

| Total Aerobic Microbial Count | max. 100 | CFU/g | — |

| Total Yeast and Molds Count | max. 50 | CFU/g | — |

| Water Content | 4.5 - 5.5 | % | KF Method |

Regulatory & Compliance

- Certifications & Compliance

- Grade

- Residual Solvents

No class 1, 2, 3 solvents are used during production. (CPMP/ICH/283/95 + CVMP/VICH/502/99)

- Certifications

- EXCIPACT certified (GMP)

- ISO 9001 and ISO 22000 certified

- Following IPEC cGMP

- On-site Batch testing & Batch release

- Certified animal Rennet-free raw materials

Technical Details & Test Data

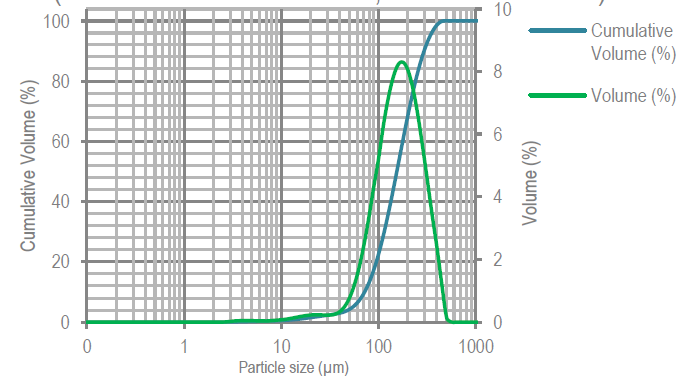

- Particle Size Distribution

PSD

(Air Jet Sieve)Specifications (%)

% < 75 µm 10 - 36 % < 150 µm 40 - 84 % < 355 µm ≥ 90 % < 500 µm ≥ 99 Our PSD specifications are determined by Air jet sieve. Different methods and equipments for PSD analysis (Air jet sieve, mechanical sieving, Rotap) can lead to different results.

PSD (Malvern Laser Diffraction, Indicative Values)

X10 : 72 µm, X50 : 154 µm, X90 : 294 µm

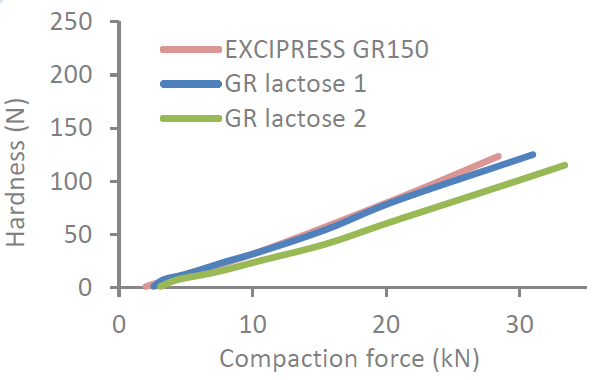

- Compressibility

EXCIPRESS™ GR 150 exhibits a very good compressibility for use in Direct Compression (DC) formulations. EXCIPRESS™ GR 150 can be considered as an alternative to other available granulated lactose products.

Compaction profile versus other GR lactoses on the market. (0.5 % magnesium stearate)

- Flowability

According to flowability index measured by Flodex, EXCIPRESS TM GR150 exhibits a “good” to “very good” flowability.

- Poured Density : 0.64 g/mL

- Tapped Density : 0.77 g/mL

- Carr’s Index : 17 %

- Hausner Ratio : 1.20

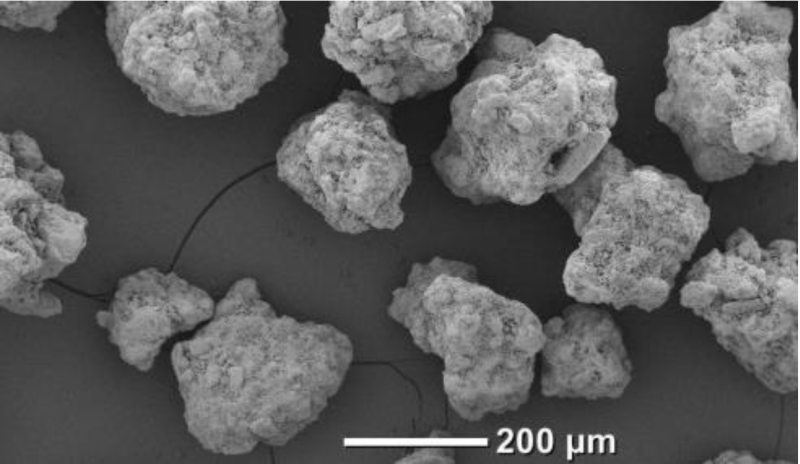

- Scanning Electron Microscopy

- Process Flow Chart

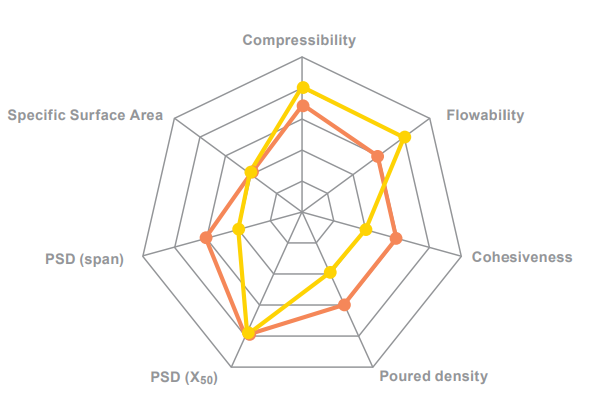

- Product Performance Characteristics

1 2 3 4 5 Compressibility Very low Low Good High Very high Flowability (Carr’s index) More than 26 21 to 25 16 to 20 11 to 15 0 to 10 Cohesiveness (Hausner ratio) 1.00 to 1.11 1.12 to 1.18 1.19 to 1.25 1.26 to 1.34 ≥ 1.35 Poured density (g/ml) Less than 0.50 0.50 to 0.59 0.60 to 0.69 0.70 to 0.79 ≥ 0.80 X50 0 to 20 21 to 50 51 to 100 101 to 200 ≥ 200 Span (PSD)* Less than 1.0 1.0 to 1.4 1.5 to 1.9 2 to 2.4 ≥ 2.5 SSA (m2/g) ≤ 0.10 0.10 to 0.40 0.41 to 0.80 0.81 to 1.40 ≥ 1.41 * Span = (X90 - X10) / X50

Packaging & Availability

- Packaging Type

Storage & Handling

- Shelf Life

- 24 Months

- Storage Information

Store in original unopened packaging, in a dry and odor free place.