Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Polymer Name

- Technologies

- Product Families

Features & Benefits

- Materials Features

- Features

- Taber Abrasion (100 cycles CS-10F wheels 500 gm load)<2.0%

- Transmission>85% (ASTM D1003)

- Thickness 0.0787”–0.375”

- Highly scratch and abrasion resistant surface

- Glossy easy to clean surface

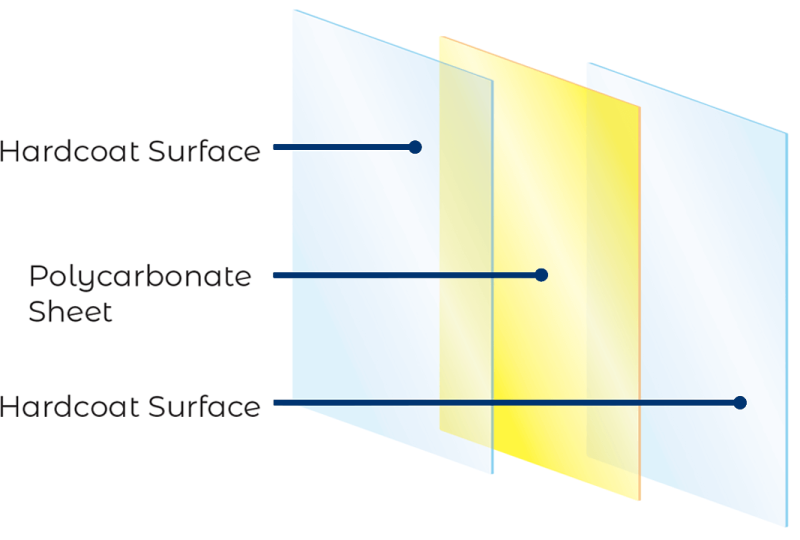

- Double side coated for improved performance

- Protective poly masking both sides Sheet

Applications & Uses

- Applications

- Plastics & Elastomers End Uses

Properties

- Physical Form

- Sheet Properties

Thickness (um) 0.0787"-0.375" Abrasion Resistance(+0000 steel wool) No visible scratches Pencil Hardness >F Haze (%) <2.0% Transmission (%) >85% Adhesion 5B Surface Energy 26 to 30 dynes

Technical Details & Test Data

- Environmental Testing

80°C 240 hours Stable -30°C 240 hours Stable Thermal Cycling (-30°C to 70°C 10 times) Stable Taber Abrasion (100 cycles CS-10F wheels 500 gm load) <2.0% - Chemical Resistance

Spot Test No change MEK No change Toulene No change Rubbing Alcohol No change Windex No change Marker No change Acetone No change - Product Construction

Packaging & Availability

- Product Availabilty

Available in sheets 48″x96″ and up to 60″x120″