Knowde Enhanced TDS

Identification & Functionality

- Product Type

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Ready-to-Use Product Features

Applications & Uses

- Markets

Properties

- Characteristics of LUBRIMATRIX™

- Lubricious

- Hydrophilic

- Biocompatible

- Thin

- Flexible

- Applicable to Small Bevel

- Autoclavable

- Durable in Dry/Wet Storage

Technical Details & Test Data

- How does HydroLAST work?

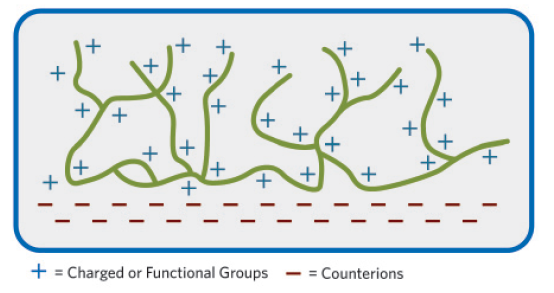

HydroLAST is a process by which hydrophilic polymers are grafted permanently to the surface of a hydrophobic substrate. The hydrophilic polymer has carboxyl, hydroxyl, or amine functionalities that serve to loosely bind water. Once treated, the substrate “wets out” and allows water and reagents to flow easily over or through it (in the case of porous substrates). Unlike conventional hydrophilic treatments such as straight plasma, corona, or ozone processing, the surface is permanently rather than transiently hydrophilic. Greater assay accuracies can be achieved, higher throughputs can be realized, and diagnostic process automation can be accomplished.

- Enhanced Hydrophilic Properties

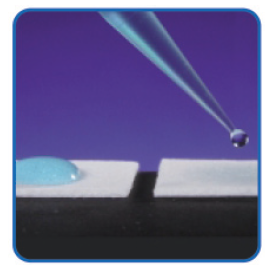

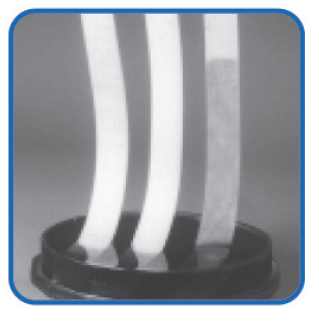

The photograph on the right illustrates the enhanced hydrophilicity imparted to ultra-high molecular weight polyethylene (UHMWPE) by HydroLAST. The untreated control does not wick any water. The oxygen treated sample shows some wicking, while the HydroLAST sample readily wicks water. In many cases, the water contact angle is reduced to zero after processing. This property is important in many diagnostic and medical device applications. Enhanced hydrophilicity is important in industrial applications where restriction of fluid flow creates problems. Examples include battery separators and printing applications.

- Stability

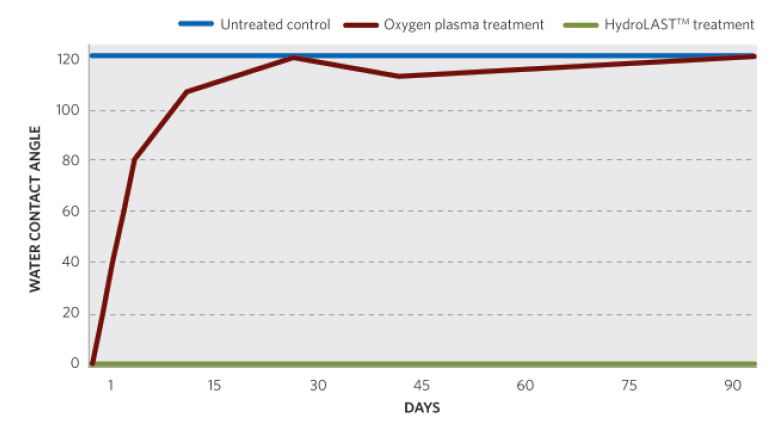

The graph below illustrates the stability of HydroLAST. After 90 days of repeated sonication, the water contact angle of treated ultra-high molecular weight polyethylene (UHMWPE) remains at zero. Within a few days, oxygen plasma treated UHMWPE has become essentially hydrophobic with a water contact angle of more than 70°. Shortly thereafter, the contact angle approaches that of the control, namely, a very hydrophobic 120°. At pH levels ranging from 2 to 13 and at elevated temperatures, HydroLAST exhibited far superior stability as compared to that of conventional plasma or corona surface treatments.

- Biocompatibility and Sterilizability

HydroLAST treated parts can be sterilized by gamma and e-beam sterilization. It is non-toxic and has passed cytotoxicity, direct hemolysis, systemic toxicity, all other biocompatibility tests associated with blood contact devices.