Knowde Enhanced TDS

Identification & Functionality

- Product Type

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Ready-to-Use Product Features

- Features & Benefits

- Conformal: ParyLAST is a tough, pin-hole free coating applicable over any complex geometry.

- Chemically Inert: ParyLAST has superior chemical resistance to nearly all known solvents.

- Tenaciously Bonded: AST’s patented parylene processing techniques (U.S. Patent Nos. 5,355,832 and 5,447,799) assure superior bonding to plastics, glasses and metals as compared to that of conventional parylene processing.

- Biocompatible: ParyLAST has demonstrated biocompatibility in long- and short-term tests.

- Environmentally Sound: The ParyLAST process is a dry process with no chemical waste or residual solvent concerns.

- Insulating: ParyLAST has exceptionally high dielectric strength and is thus suitable as an insulating material in medical products.

Applications & Uses

- Markets

Properties

- Electrical Properties

| Value | Units | Test Method / Conditions | |

| Dielectric Strength (Short Time, 1mil) | 6800.0 | Volts/mil | - |

| Volume Resistivity (23°C, 50% RH) | 6.0e+16 | Ohm-cm | - |

| Surface Resistivity (23°C, 50% RH) | 1.0e+15 | Ohm-cm | - |

| Dielectric Constant (60Hz) | 3.15 | - | - |

| Dielectric Constant (1000Hz) | 3.1 | - | - |

| Dissipation Factor (60Hz) | 0.02 | - | - |

| Dissipation Factor (1,000Hz) | 0.02 | - | - |

| Dissipation Factor (1,000,000Hz) | 0.01 | - | - |

Regulatory & Compliance

- Certifications & Compliance

- Accepted

ParyLAST has a long history of use and can be found in a number of FDA-approved implantable devices.

Technical Details & Test Data

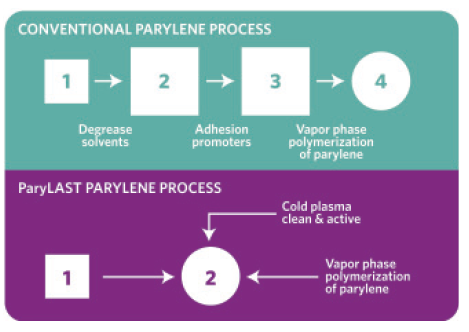

- How is ParyLAST different from conventional parylene?

In conventional parylene deposition, parts are first cleaned. Often this cleaning is done with a degreasing solvent. Next, they are soaked in adhesion promoters to improve the inherently poor adhesion of parylene. Lastly, the parylene is vapor deposited on the parts in a vacuum chamber.

ParyLAST overcomes parylene’s adhesion limitations by creating molecular level binding between the substrate and the parylene coating. This is achieved by the integration of plasma cleaning and vapor deposition. When parts are to be treated with ParyLAST, they are placed into the patented reactor. First, they are cleaned and surface activated via a gas plasma molecular activation surface treatment. Then, without breaking containment, parylene is deposited on the surface via the standard vapor-polymerization process. The resulting ParyLAST coating, while chemically identical to conventionally applied parylene, is unlike it in that it is a coating with a lifetime resistance to delamination and minimized component failure due to liquid propagation into the coating/substrate interface.

- Chemical Resistance

All Values are in cm³-mil/100in²- 24hr-atm at 23°C

Nitrogen 0.95 Oxygen 7.1 Carbon Dioxide 7.7 Hydrogen Sulfide 13 Sulfur Dioxide 11 Chlorine 0.35 Moisture 0.14 at 37°C and 90%RH - Saline Soak Test

- Tenacious Bonding

Method: ASTM D3359-95A “TAPE TEST”

Coating is cut into an “X” or into a crosshatch pattern per protocol. The coating is covered with #810 Scotch TapeTM and then the tape is pulled off. The degree of coating damage is qualitatively assessed. 0 means removal of the coating beyond the cut area while 5 means no peeling or removal. Intermediate numbers refer to result between these two extremes. From the data, ParyLAST clearly demonstrates superior adhesion.

CUTTING PATTERN ADHESION RATING Conventional Parylene ParyLASTTM X-Cut Pattern 0 (10 measurements) 5 (31 measurements) Cross-Hatch Pattern 0 (16 measurements) 5 (16 measurements) - Biocompatibility and Sterilization

ParyLAST can be sterilized via ETO, gamma radiation, or e-beam sterilization.

ParyLASTTM Has Passed the Following Biocompatibility Tests:

- Intracutaneous reactivity

- Muscle implantation (14 days and 6 months)

- Systemic toxicity

- Cytotoxicity

- Sub-chronic toxicity

- Hemocompatibility

- Ames mutagenicity