Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Polymer Name

- Reinforcement Material

- Composite Materials Functions

- Technologies

Features & Benefits

- Materials Features

- Benefits

The CSMC(Carbon Fiber Sheet Molding Compound) is a polymer composite material reinforced with carbon fiber, which consists of a thermoset resin (usually vinylester or epoxy) and different additives that allow to obtain certain specific characteristics and improve the behavior of the material during the molding process of the final product. While the standard SMC is reinforced with glass fibers, the CSMC is reinforced with cut fibers or carbon fabrics. CSMC materials combine the low-weight characteristics offered by carbon composites in conjunction with a widespread forming process, such as compression molding, which allows for short manufacturing cycles and is therefore suitable for industrial applications in large series.

- Features

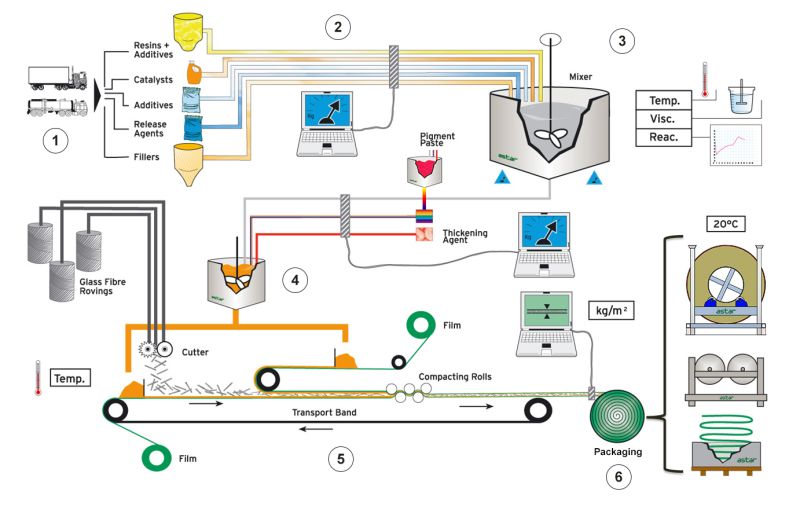

Resins and additives are automatically weighted and mixed together. The color pigments and thickeners are measured and mixed continuously with the mother paste in a computer-controlled process forming the impregnation paste. The impregnation paste is immediately transferred to the carbon fiber impregnation line. The impregnation paste is transferred to a doctor box where it is deposited onto a moving carrier film. Simultaneously the carbon fiber is chopped to a pre-determined length and dropped onto the layer of paste. A second film is coated with a layer of paste and then used to cover the fiber cuttings creating a “sandwich”. The resulting sheet is then sent through a series of compaction rollers to ensure a perfect impregnation or wet out of the chopped fiber. At the end of the impregnation line, the sheet can be rolled up using MegaRolls or MiniRolls.

Applications & Uses

- Markets

- Applications

- Plastics & Elastomers End Uses

- Composites Processing Methods

Properties

- Physical Form

Regulatory & Compliance

Technical Details & Test Data

- Maturation and Conservation

CSMC must mature before it reaches optimal conditions for molding. The resin paste changes from a liquid state during manufacturing to a semi-solid state at its optimal condition period. This change in viscosity is achieved through the introduction of the thickening agent during manufacturing. Typically the required maturation time is between 2 and 4 days, depending on the specific formulation. Even after the material has matured, it continues to thicken at a speed dependant on the storage temperature. Therefore there is an optimal utilization period of typically, between 1 and 6 months, dependant mainly on the specific formulation and storage temperature, which is recommended to be between 5ºC and 25ºC. Higher storage temperatures can significantly reduce the usability time of CSMC.