Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Polymer Name

- Reinforcement Material

- Composite Materials Functions

- Technologies

- Maturation and Conservation

SMC must mature before it reaches optimal conditions for molding. The resin paste changes from a liquid state during manufacturing to a semi-solid state at its optimal condition period. This change in viscosity is achieved through the introduction of the thickening agent during manufacturing. Typically the required maturation time is between 2 and 4 days, depending on the specific formulation. Even after the material has matured, it continues to thicken at a speed dependant on the storage temperature. Therefore there is an optimal utilization period of typically, between 1 and 6 months, dependant mainly on the specific formulation and storage temperature, which is recommended to be between 5ºC and 25ºC.

Features & Benefits

- Materials Features

- Benefits

Your customers demand structural materials that are lightweight, strong and versatile. Materials that resist corrosion and temperature extremes and which deliver freedom of design and low system costs. The ideal solution for many applications is a family of structural, fiber reinforced thermosets: SMC (Sheet Molding Compound) and BMC (Bulk Molding Compound). These materials combine mechanical and physical properties with the lowest system cost, without compromising quality

Applications & Uses

- Markets

- Applications

- Plastics & Elastomers End Uses

- Composites Processing Methods

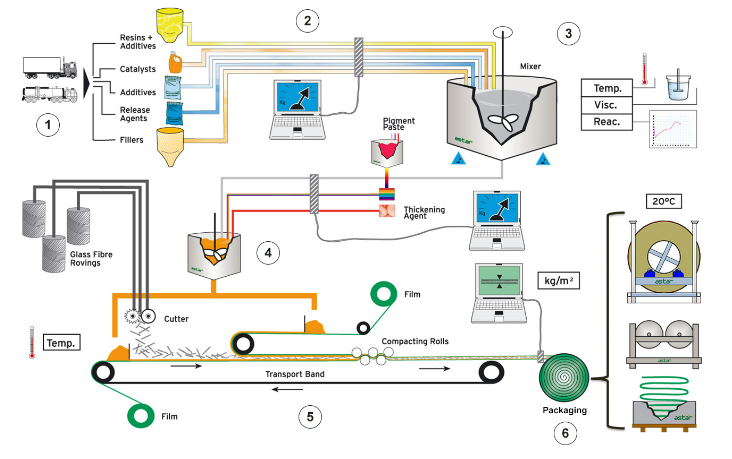

- SMC Manufacturing Process

Resins, fillers and additives are automatically weighted and mixed together. The color pigments and thickeners are measured and mixed continuously with the mother paste in a computer-controlled process forming the impregnation paste. The impregnation paste is immediately transferred to the glass fiber impregnation line.

The impregnation paste is transferred to a doctor box where it is deposited onto a moving carrier film. Simultaneously the glass fiber is chopped to a pre-determined length and dropped onto the layer of paste. A second film is coated with a layer of paste and then used to cover the fiber cuttings creating a “sandwich”.

The resulting sheet is then sent through a series of compaction rollers to ensure a perfect impregnation or wet out of the chopped fiber. At the end of the impregnation line, the sheet can be rolled up using rolls, MegaRolls or folded into boxes.

- Applications

SMC applications are wide-ranging in the Automotive & Transportation, Electrical & Energy, Building & Construction, Industrial, Service, Sanitary, Domestic and Medical markets.

Electrical & Electronics (mechanical integrity and electrical insulation)

- Low voltage and medium voltage energy systems

- Fuses and switchgear

- Cabinets and junction boxes

- Motor and anchor insulations

- Encapsulation of wiring and electronic circuits

- Electrical components with reduced surface resistivity

- Lamp housings

Mass Transportation (light weight and fire resistance)

- Train, tram interior and body parts

- Electrical components

- Track switch components

- Under the hood components for trucks

Automotive & Truck (low fuel emissions through weight reduction)

- Light weight body panels for vehicles

- Lighting systems, headlamp reflectors and LED lighting

- Structural parts, front ends, interior dashboard parts

- body panels for trucks and agricultural vehicles

Building & Construction (durability and design freedom)

- Drinking water tanks

- Panels

- Doors

- Building supply systems

- Drain and trench covers

- Access chambers

Domestic Appliances (manufacturing in large volumes)

- Iron heat shields

- Coffee machine components

- Microwave ware

- White goods components, grips and handles

- Pump housings as metal substitution

- Motor housings as metal substitution

Engineering (strength and durability)

- Functional parts in mechanical engineering as metal substitution

- Pump components for various media

- Sport equipment, golf caddy

- Safety products for leisure and public application

Sanitary (design freedom and personalized esthetics)

- Sinks and bath tubs

- Toilet seats

- Drain covers

Medical (optmized shape and user friendliness)

- Surgery equipment

- Dental medication systems

- Antibacterial component

Properties

- Physical Form

- Typical Properties

- Properties

Strength and stiffness: The combination of fibers, fillers and resin results in material systems with great stiffness and mechanical strength. The resin provides the ductility, durability and system cohesion. The fibers are largely contributing to strength and stiffness. Glass fibers, carbon fibers and combinations of the two are being used.

Part safety through great Fire retardance: Elevated resistance to fire and low smoke generation is important for many applications and markets. For obtaining this high flame retardency a number of additives can be used. SMC & BMC do not contain any halogens or other hazardous flame retardants. Still they can be formulated having excellent FR properties, even at very low wall thicknesses

Weight reduction: For reducing Eco-footprint and fuel emission, SMC & BMC Composite solutions can enable manufacturing components with less weight. The mechanical properties of SMC & BMC Composite solutions help to easily replace a large number of metal parts by few composite parts

Precision and predictability of dimensions: SMC are first choice solutions for substitution of high performance metal parts where high precision is obtained by means of post-machining processes. Tight tolerances can be produced directly without post operations, ensuring not only cost savings but also increased profitability. As a main advantage compared to equivalent non-thermoset polymers, the ability to compensate shrinkage with special additives makes even most challenging part designs feasible. For parts with highest precision, materials with negative shrinkage (expansion) can even be used.

Resisting elevated temperatures: Many thermoset polymers are known for their excellent thermal resistance. Using specific resin systems thermal resistances up to 300°C can be achieved. From a technical view these materials can be superior to engineering thermoplastics and provide cost effective solutions especially in comparison to high performance thermoplastics. For demanding engineering applications it is also crucial that the CTE (Coefficient of Thermal Expansion) is close to the CTE of metals and ensures dimensional stability over a wide range of temperatures

Great Class A surfaces: The ability to obtain excellent surfaces for online- and offline painting, as well as for part metallization is a great asset of working with both SMC & BMC Composite solutions. superior surface esthetics can be obtained through the unique technology to compensate the material shrinkage.

Low emissions: Interior parts in many end use markets require low emission materials (e.g. car interior parts). Minimization of hazardous or uncomfortable emissions and smell is desired. Also in lighting systems the headlamp reflectors must be free of any emissions in order to avoid fogging, that will reduce lighting performance

| Value | Units | Test Method / Conditions | |

| Fire Retardancy (3mm) | 5VA | mm | UL 94 |

| Fire Retardancy (3mm) | 4.5 | mm | UL 94 |

| Limited Oxygen Index | 30.0 | % | ISO 4589-2 |

| Glow Wire Test(1.5mm) | 960.0 | °C | IEC 60695 |

| Poison Ratio | 0.3 | — | ISO 527 |

| Water Absorption | max. 0.3 | — | ISO 62 |

| Comparative Tracking Index | CTI 600 | — | IEC 60612 |

Regulatory & Compliance

Packaging & Availability

- Packaging

Products come as a sheet 1500 mm wide supplied either on ≈450 kg rolls, on ≈1400 kg MegaRolls, or folded like computer paper in ≈1150 kg boxes.

Storage & Handling

- Storage

Higher storage temperatures can significantly reduce the usability time of SMC.