Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Product Type

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Ready-to-Use Product Features

- Advantages

- AVM Top Coat Sealer 4150 prevents future deterioration due to exposure to moisture, freeze thaw and weather extremes. It has low VOCs, is environmentally friendly and harmless to the surrounding vegetation, glass, metal, etc.

- It is non toxic, non-flammable and has no odor when dry. It helps stop efflorescence and prevents moisture and water from leaching through.

Applications & Uses

- Markets

- Applications

- Where to Use

AVM Top Coat Sealer 4150 is formulated for use on decks and porous materials such as concrete blocks, masonry blocks, bricks, sandstone, split face blocks, stucco, exterior wood and other common exterior surfaces.

- Project Conditions & System Application

Project Conditions

- Do not apply materials at temperatures below 50°F, or if precipitation is imminent, or above 90°F if applying in direct sun light.

- Provide adequate ventilation during installation.

- Warn personnel against hazards of materials to skin and eyes.

- Protect adjacent surfaces which could be damaged during the application.

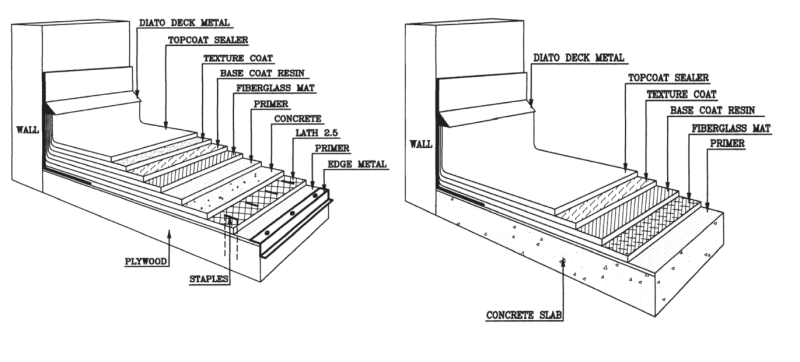

System Application

Install the Top Coat Sealer 4150 in accordance with its Installation Instructions.

Preparation

The substrate surfaces must be structurally sound, clean, dry, free of efflorescence, dust, dirt, silicone, oil and other contaminants that would prevent the proper penetration and bonding of the AVM Top Coat Sealer 4150. Joints or cracks should be sealed or filled prior to the application of the AVM Top Coat Sealer 4150. Remove all existing coatings, paints, etc, prior to the application. For proper bonding, it is recommended to sandblast or water-blast cementitious surfaces (blocks, slabs, bricks, etc) scheduled to receive the AVM Top Coat Sealer 4150.

- Installation & Protection of Installed Work

Installation

The AVM Top Coat Sealer 4150 can be applied using low pressure airless spray equipment using a fan type spray tip with orifice size from 0.018 to 0.035 inches. Hold spray tip approximately 12-18 inches from the surface. The AVM Top Coat Sealer 4150 can also be brushed or rolled on using a long nap roller cover. Do not over apply material. (Apply thin coats) If necessary, apply a second coat. Highly porous or difficult to paint substrates, such as split face or Routed blocks, raked joints, etc, may need a second coat to ensure complete and proper coverage and protection. A second application can be made anytime after the first coat has completely cured. For best results however, allow twenty four hours between coats.

Quality Control

- Visually inspect all coated surfaces to ensure a full and proper coating application, especially at corners, drainage scuppers and hard-to-reach areas.

- All unsatisfactory areas shall be repaired prior to final acceptance.

Protection of Installed Work

The completed section shall be protected from all pedestrian traffic for the first 24 hours after application and until the surface is sufficiently cured. (The amount of drying time may vary depending on temperature and humidity conditions) Typically, light foot traffic may resume after 4-6 hours.

Clean Up

Tools may be cleaned with water before resins are dry. Maintenance Periodic cleaning and maintenance is required.

Coverage

Materials Over Deck Coatings Over Semi-Smooth Concrete Over Porous Surfaces

AVM Top Coat Sealer Ist coat 100-120 sq. ft./gal. 100-150 sq. ft./gal. 75-100 sq. ft./gal.

AVM Top Coat Sealer 2nd Coat 150 sq. ft/gal. 150+ sq. ft./gal. 100+ sq. ft./gal. - Limitations

- The AVM Top Coat Sealer 4150 is not recommended for outdoor below grade applications or on walls where the dirt rests against them.(retaining walls, planters, etc) Neither is it recommended for interior use on below grade walls (waterproofing from the inside) on areas such as subterranean walls, parking structure walls, basement walls, or where water is penetrating or seeping through walls from the outside.

- In addition, it will not prevent water penetration through unsound or cracked surfaces.

Properties

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Abrasion | 4.58 | % | - |

| Bond Strength (Once Cured) | 134.0 | PSI | - |

| VOC | 99.0 | Grams/Liter | - |

Technical Details & Test Data

- Technical Data

Weatherometer No Cracking, Softening, Crazing

Wind Uplift Tested/passed -227 MPH) Approved at 90 MPH

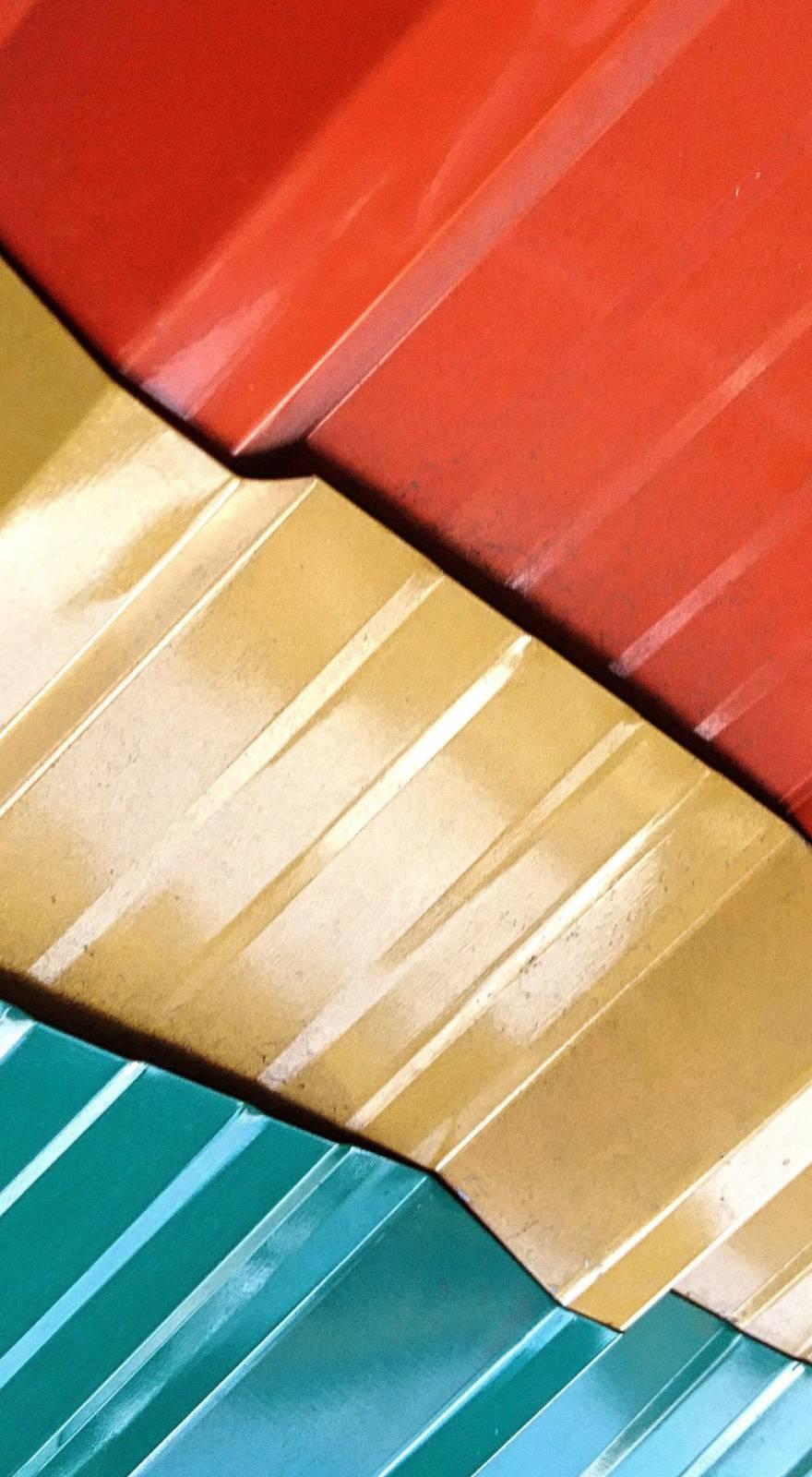

Top Coat Colors 30 Standard colors

Top Coat Colors Custom colors are available

Packaging & Availability

- Approximate Shipping Weights

- 19.0 lbs. - 47.0 lbs

- Packaging

2.0/5.0 gal. pails

Storage & Handling

- Delivery, Storage, and Handling

- Delivery of the AVM Top Coat Sealer 4150 must be in its original sealed containers, with manufacturer’s name and label intact.

- Handle and store containers and bags in accordance with printed instructions.

- Store at temperatures between 50°F and 90°F. Do not store materials in direct sunlight or where they may be damaged by water or rain. Bags must be kept dry. If frozen, discard.

- Keep all materials out of the reach of children.

- If irritation occurs during use, liberally flush affected areas with water. If irritation continues, see a physician immediately.

- Shelf life is one year form manufacturing date in sealed, unopened containers.

- Shelf Life: (Liquids) One year in original unopened packaging.