Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Chemical Name

- Base Chemicals Functions

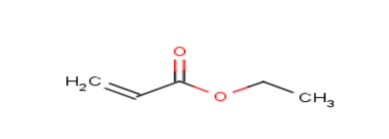

- Molecular Formula

- C5H8O2

- CAS No.

- 140-88-5

- EC No.

- 205-438-8

- Technologies

- Product Families

- Structure

Features & Benefits

- Labeling Claims

Applications & Uses

- Markets

- Applications

- Base Chemicals End Uses

- Use and Applications

Acrylate esters, the family of chemicals to which EA belongs, are used primarily as reactive building blocks to produce coatings and inks, adhesives, sealants, textiles, plastics and

elastomers. The acrylate esters typically are present only in trace amounts (as residual monomer) in the finished product. Specifically, EA is used in the following applications:- Adhesives: for use in construction and pressure-sensitive adhesives as a co-monomer

- Chemical intermediates: for a variety of chemical products. The most prominent use as an intermediate is to produce dimethylaminoethylacrylate (DMAEA), which is used as a monomer to make flocculants for water treatment.

- Coatings: monomers used to produce polymers for architectural, decorative, industrial, paper and roof coatings

- Leather: to produce different polymer finishes, particularly nubuck and suede

- Plastics: for the manufacture of a variety of plastics

- Fibers: in the manufacture of fibers of both woven and non-woven textiles as a copolymer of e.g. acrylonitrile and EA. The fibers are in turn used for e.g. the manufacture of textiles.

Ethyl acrylate is not sold for direct consumer use, but it is used as a raw material to make a variety of goods used by consumers or construction personnel and could be present in trace amounts as residual monomer in consumer products, including paints.

Properties

- Physical Form

- Odor

- Pungent

- Physico-Chemical Properties

| Value | Units | Test Method / Conditions | |

| Density (20°C) | 0.92 | g/cm3 | — |

| Melting Point (1013hpa) | -71.2 | °C | — |

| Flammability | Highly flammable liquid and vapor | — | — |

| Explosive Properties | Non explosive | — | — |

| Boiling Point (1013 hPa) | 99.8 | °C | — |

| Self-ignition Temperature | 372 | °C | — |

| Vapor Pressure (20.9°C) | 40 | hPa | — |

| Molecular Weight | 100.12 | — | — |

| Water Solubility (20°C) | 20 | g/l | — |

| Flash Point | 9 | °C | — |

| Octanol-water partition coefficient (Log Pow) (25°C) | 1.18 | — | — |

Regulatory & Compliance

- Certifications & Compliance

- Regulatory Information

This substance is subject to a number of federal and international statutes and regulations. Selected U.S. regulatory information is available on the BAMM website. Other federal, state and local regulations may apply.

This substance has been registered under EU chemical control law known as REACH (Registration, Evaluation, Authorisation and Restriction of Chemical substances), and is listed on various chemical inventories. It has been reviewed under the OECD SIDS (Screening Information Data Set) program.

While the toxicological data are not specific to a particular region, the regulatory frameworks differ between countries and regions. The Global Harmonized System (GHS) attempts to standardize hazard communication so that the intended audience (workers, consumers, transport workers, and emergency responders) can better understand the hazards of the chemicals in use. Under the GHS, substances are classified according to their physical, health, and environmental hazards.

Hazard statements:

H225: Highly flammable liquid and vapor.

H302: Harmful if swallowed.

H312: Harmful in contact with skin.

H315: Causes skin irritation.

H317: May cause an allergic skin reaction.

H319: Causes serious eye irritation.

H331: Toxic if inhaled.

H335: May cause respiratory irritation.

H412: Harmful to aquatic life with long lasting effects

Safety & Health

- Human Health Safety Assessment

Acrylate esters, including EA, have a very strong, unpleasant odor that may be bothersome. However, the smell of acrylates does not necessarily indicate a health hazard.

Like any reactive chemical, EA can create hazards if not handled properly. It is toxic if inhaled or harmful with skin contact. It causes irritation to skin, eyes and the respiratory tract. Repeated skin contact may cause allergic reactions. It has a low toxicity if swallowed. Animal studies have not indicated that it causes cancer or reproductive toxicity.

- Environmental Safety Assessment

Ethyl acrylate is a liquid which evaporates easily and is unlikely to persist in the environment. It is not expected to bind to soil or sediment. If released to air, it will undergo degradation within days. It is not expected to accumulate in the food chain, i.e., the bioconcentration potential is low. It biodegrades rapidly in the environment. EA is toxic to aquatic organisms (fish, algae, invertebrates).

- Exposure

Human health

Ethyl acrylate is used in the production of industrial and consumer products. Based on these uses, the public could be exposed through:

- Workplace exposure – Exposure can occur either in an EA manufacturing facility or in the various industrial or manufacturing facilities that use EA. It is produced, distributed, stored and consumed in closed systems. Those working with EA in manufacturing operations could be exposed during maintenance, sampling, testing, manual transfer, or other procedures.

- Consumer exposure to products containing ethyl acrylate –EA is not sold for direct consumer use, but it is used as a raw material to make a variety of goods used by consumers or construction personnel and could be present in trace amounts as residual monomer in consumer products, including paints.

Environment

Potential releases into the environment are limited and for the most part occur only during production and processing, typically via wastewater and exhaust gasses. If accidentally released to surface water, it rapidly biodegrades and will not persist in the environment and will not accumulate in the food chain.

- Risk Management Recommendations

Industrial Manufacturing and Processing

In industrial manufacturing and processing applications, it is always important to obtain a current Safety Data Sheet from your supplier, follow the guidance provided and comply with applicable regulations.

Acrylic acids, acrylates and products containing them should always be handled in well ventilated areas. Each manufacturing facility should have a thorough training program for employees, appropriate work processes, and safety equipment in place to limit unnecessary exposure.

In the event of a spill, the focus is on containing the spill to prevent contamination of soil, ditches, sewers, or surface or ground water. Only trained and properly protected personnel should be involved in clean-up operations.

Professional Applications

Before using any chemical product, the user should be properly trained in safe handling procedures for that product. This means that they should always contact the supplier of the product being used to obtain the most current safe handling advice and follow all instructions and warnings.

Consumer Applications

It is important to read and follow all warnings and instructions on the product label or packaging