Knowde Enhanced TDS

Identification & Functionality

- Chemical Name

- Plastics & Elastomers Functions

- CAS No.

- 82451-48-7

- EC No.

- 617-335-9

- Technologies

- Product Families

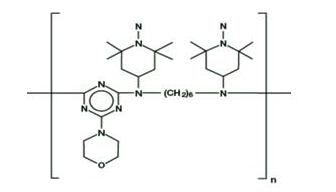

- Structure

Features & Benefits

- Materials Features

- Characteristics

- Minimal color contribution

- Low volatility

- Excellent compatibility with other HALS and UVA

- Good solubility/migration balance

Applications & Uses

- Applications

- Compatible Polymers & Resins

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

Properties

- Physical Form

- Appearance

- White to yellowish solid

- Soluble in

- Toluene

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Annual Output | 250 | MT | — |

| Loss on Drying | max. 0.8 | % | — |

| Melting Point | 100 - 125 | °C | — |

| Molecular Weight | 1600 ± 10 | % | — |

Packaging & Availability

- Packaging Type

- Packing

Generally 25kgs/ctn, 45ctns/pallet, 10 pallets in a 20GP container or according to customers requirement.