Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Product Type

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

- Features

- Two Component

- No Limited Pot Life or Finish Wasted

- Colorless, Clear Finish Clarity

- Superior Flow, Leveling and Low Foam Formula

- Low Non-Offensive Odor

- Available in Gloss

- Excellent durability and chemical resistance

- Easy to apply and screens well

- Product Highlights

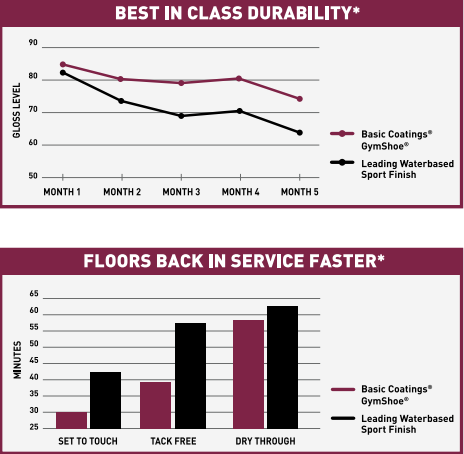

GymShoe® is an exceptionally durable sport floor finish that keeps floors looking better longer. GymShoe is perfect for large sport complexes, higher education, dance floors, retail and commercial space or any high traffic sports facilities. With superior two-component performance you can be confident that GymShoe will hold up to even the busiest of gyms. It offers the performance and protection you need. With exceptional durability and best in class dry times it is the choice for all your sports floor needs. Basic Coatings GymShoe keeps sports floors looking better longer! GymShoe® is clear, dries faster than competitive waterbased finishes, and its durability allows the floor to look better for longer.

- GymShoe Advantages

- Clear, Non-Yellowing Urethane

- 24 Hour Pot Life (Once Catalyzed); Can Be Re-catalyzed

- Great Shine, ResistHeel Marks

- PowderWell During Application

- 7 Day Cure

- Fast Drying (2-3 Hours); LesDowntime

- Coverage is: 500 - 700 sq. ft. Per Gallon

Applications & Uses

- Markets

- Application Method

- Recommended Uses

- Commercial and Sports Floors

- Ideal for preserving the Original Color of Stained Floors

- Application

Use Basic Coatings® T-bar, trim pad, roller or brush.

Recommended Systems

- New Installations/Newly Sanded Floors - 2 coats Basic Coatings’ Waterbased Sealer and 2 coats GymShoe

- Screen and Recoat - 1-2 coats GymShoe

- TyKote® and Recoat -1 thin coat Basic Coatings TyKote and 1 coat GymShoe

Over Stains And Game Line Paints

- For Stains: Allow stains to dry per manufacturer’s directions or longer depending on environmental conditions. Apply 1-2 coats of a Basic Coatings Waterbased Sealer and 2 coats GymShoe.

- For Game Line Paints: Please refer to Basic Coatings Technical Bulletin, Approved Game Line Paints and Procedure, for proper application and a current list of approved paints.

- Note: A test board is recommended with any stain/game line paint to insure compatibility and color acceptance.

Adding Water

Up to 12 ounces of water can be added per gallon of finish. Adding water will increase the flow and level time during situations of high temperature and low humidity.

Surface Preparation

- Sand floors using accepted NWFA/MFMA procedures. All old finish must be removed. A NIOSH approved dust mask should be worn during sanding.

- Finish sanding with new 120 - 150 grit screens. DO NOT USE STEEL WOOL.

- Vacuum. Tack with clean Basic Coatings Microfiber Mop until all dust has been removed.

Finish Application

Always maintain adequate ventilation during all phases of the coating and drying process.

- Use a stir stick to re-disperse any settlement, rock container several times.

- Set aside for 10 minutes to allow bubbles to break.

- Measure and record moisture content of the floor in several areas.

- Rinse finish applicator and remove all excess water to remove loose applicator fibers.

- Edge out about 6 inches from baseboard or wall with a paint pad or polyester brush. Stay within 2- 3 feet of the finish line to avoid lap marks, streaking or thicker film build. Be sure to feather the edge.

- Starting about one foot from the head wall, pour a 4-inch wide line of finish the length of the floor going with the grain. Stop about three feet from the opposite wall. As close to the wall as possible, hold the applicator at a slight angle and drag it in a “squeegee” or “plowing” type motion to move the puddle from one side of the room to the other. Overlap two inches of the last pass and pull parallel passes until the entire floor is coated. Brush out all turns, stops, and other applicator marks brushing in the direction of the grain of the wood. Feather out turns with a painters pad after the T-bar has made the turn. Add finish to the puddle-line when needed to maintain a wet edge across the room. For more information on coating procedures and tips visit the training section at basiccoatings.com.

- When 2-3 feet from exiting wall, begin to taper the puddle-line down to a nickel size bead. Back out of the room by wetting small sections of the remaining floor, brushing away from you in the same direction as the grain of the wood.

- Allow each coat a minimum of 30 to 45 minutes to level.

- After finish levels, place fans in an adjacent area to pull moisture away from the job site. When each coat has dried a minimum of 2-3 hours, re-measure moisture content. If moisture content is not equal to the first reading, allow more dry time before proceeding to the next coat.

- If necessary, abrade between coats to remove debris, hair, drips, etc. or if the 24-hour window between coats has elapsed. Abrade with the pad and strip system, using 180-240 grit sanding strips. Vacuum and tack with the Basic Microfiber Mop in between coats.

- If the 24-hour window has elapsed, the Basic Coatings® TyKote® Dust-Free Refinishing System is an alternative to screening the floor. Refer to Tykote application procedures for details.

- Apply all subsequent coats in the same manner.

Recoating Procedures

DO NOT USE GymShoe® over waxed surfaces. See Basic Coatings Technical Bulletin, Testing and Removal Procedure for Acrylic Polish and Paste Wax.

- Tack the floor with Basic Coatings Squeaky™ Cleaner per label directions.

- Abrade with new 100 or 120-grit screens or use the pad and strip system. DO NOT USE STEEL WOOL.

- Vacuum. Tack the floor with a clean Basic Coatings Microfiber Pad until all dust has been removed.

- Apply 1 - 2 coats GymShoe using the procedures outlined above.

Dry Time

Allow at least 2-3 hours between coats and 1 hour of good ventilation before closing job site. Keep air moving over floor for several hours. The floor may be opened to light traffic and furniture replaced after 24 hours dry time; however, it is susceptible to scuffing or marring. Finish will reach full cure in approximately 7 days. Do not place carpet, rugs, or cover the finish for at least two weeks after coating.

Daily Maintenance

Do not use any liquid cleaners other than water for the first 2 weeks. Use Basic Squeaky Cleaner as directed for routine cleaning and maintenance once the 2-week window has passed. See Basic Coatings maintenance brochures for additional instructions.

Properties

- Color

- Odor

- Mild

- Typical Properties

- Specifications

Gymnasium water-based floor finish, two-component system in five-gallon containers as per the following specifications. Product shall be cross-linked with Polyfunctional Aziridine, water-based urethane/acrylic system with a solids content of 30% NVM or higher. The maximum VOC requirement is to be added when federal, state or local restrictions apply. Batch numbers must appear on the outside of each container. Label shall state usage per square foot per gallon. Ease of application shall be tested by using the manufacturer's recommended applicator. The material shall be workable so the working edge shall not dry or become tacky and that the next width can be applied without difficulty. When an entire floor has been completed using normal methods, there shall be no visible lap marks or other defects.

| Value | Units | Test Method / Conditions | |

| Solids Content | 30.0 | % | - |

| Chemical Resistance | Excellent | - | - |

| Defoaming | Excellent | - | - |

| Leveling | Excellent | - | - |

| VOC | max. 275 | grams/liter | - |

| Gloss at 60° | min. 85 | % | - |

| Dry Time | 2 - 3 | hours | - |

| Coverage | 500 - 700 | sq. ft./Gallon | - |

| Flash Point | min. 212 | ºF | - |

| Catalyzed/Cross-linked | Yes - Aziridine | - | - |

| Recoat time (Per coat) | Recoat within 24 | hrs | - |

| Slip Resistance (Coefficient of friction) | Meets or exceeds 0.5 | - | ASTM D2047- 04 |

| Viscosity | 70 - 100 | centipoise | - |

| Sheen | Gloss | - | - |

Regulatory & Compliance

- Approvals

MFMA Approved, Maple Flooring Manufacturers Association, Inc.

Technical Details & Test Data

- Technical Details

Safety & Health

- Precaution

Keep out of reach of children. For industry use.

Caution: May cause eye irritation. Use with adequate ventilation. Avoid contact with eyes, skin and clothing. Wash thoroughly after handling. Do not ingest. Keep closures tight and upright to prevent leakage. Keep container closed. In case of spillage, absorb and dispose of in accordance with local applicable regulations.

First Aid:

If In Eyes: Flush with large quantities of water. Call a physician if irritation persists.

If Swallowed: Do Not induce vomiting. Rinse out mouth with water. Call a physician.

Packaging & Availability

- Packaging

5 U.S. gallon pail.

Storage & Handling

- Pot Life

24 hours (After catalyzed)

- Storage

- Do not store above 120ºF (49ºC).

- Stability - 1 year shelf life under proper storage conditions.

- Shelf Life - 1-Year unopened; properly stored