Knowde Enhanced TDS

Identification & Functionality

- Ingredient Name

- Food Ingredients Functions

- Ingredients

- Hops Extract

- Technologies

Features & Benefits

- Labeling Claims

- Food Ingredients Features

- Product Highlights

- LactoStab® is proven effective - Ethanol production facilities, as well as numerous scientific studies, have proven that LactoStab® works as promised. These higher pH plants have inhibited infection and eliminated the use of antibiotics and produced more valuable co-products

- The natural secret behind LactoStab® - The hops cone has been used for centuries to provide flavor, aroma, and preservation for beer. But hidden within that cone are compounds that have natural antimicrobial functionalities. BetaTec discovered a way to extract and isolate these compounds, and provide a product with bacteriostatic and bactericidal activity against gram-positive bacteria. The result is naturally derived LactoStab®

- LactoStab® Features & Benefits

- Safe, naturally-derived, food grade product

- Eliminates the need for chemical antibiotics and harsh chemicals

- Effectively inhibits lactic acid bacteria

- Ideal for use in higher pH plants

- No effect on yeast activity or vitality

- Increases profits with higher value antibiotic-free co-products

- Cost effective to use

- Thermally stable

- Key Advantages of LactoStab®

- Selectively inhibit common Gram-positive bacteria found in yeast fermentations

- May be used in seed, commercial or extraction stages

- Does not harm yeast or impact its performance

- Quality, yield, activity, storage and taste of yeast are not negatively affected

- Can be used preventatively or as a standby

- Reduce contamination carry-over into other applications, e.g. alcoholic fermentations

- Improves your yeast plant operations

- Ease of downstream processing

- Clean label friendly

- Eliminates the use of antibiotics

- Controls lactic and acetic acid formation

- Adds value to co-products with antibiotic-free DDGs

- Protects your equipment from harsh chemical

- Derived from the natural growing hop plant

- Thermally stable

- pH tolerant

- Easy to handle and store

- Food grade, Kosher, Halal, GRAS, safe to handle

- Cost effective

- “Invisible” to yeast, with no negative effect on yeast activity or vitality

Applications & Uses

- Markets

- Food & Nutrition Applications

- LactoStab® Pro Action Mechanism

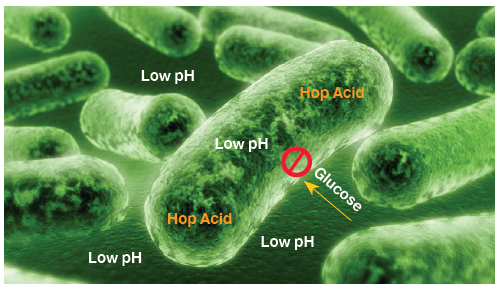

BetaTec extracts naturally occurring acids from the hops flower to produce LactoStab®. These natural acids are absorbed by the bacteria cell and lower its pH. This inhibits the cell’s ability to transfer glucose through the cell wall. In essence, bacteria commonly found in ethanol production are starved to death. They can’t eat. They can’t multiply. And they die. All without the use of chemical antibiotics. Better yet, the bacteria do not recognize LactoStab® as a threat, and therefore do not develop a resistance. In fact, without competition from bacteria, yeast do their job more effectively and alcohol yield benefits.

- Directions for Use

- You can pump or pour LactoStab® directly into the propagation tank

- You can also add LactoStab® in through the propagation/mix tank

- No additional preparation is required before use

Properties

- Physical Form

- Typical Properties

| Value | Units | Test Method / Conditions | |

| pH | 5.0 - 6.0 | — | — |

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- LactoStab® in Ethanol Production

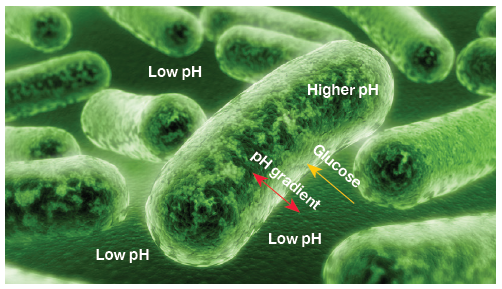

Bacteria cells take nourishment by absorbing glucose through their cell membrane. Without the presence of LactoStab®, the pH gradient across the cytoplasmic membrane allows the uptake of glucose by lactic acid bacteria resulting in infection and lower ethanol yields.

By adding LactoStab®, the hop-based product dissipates the pH gradient across the cytoplasmic membrane of lactic acid bacteria. Consequently, the lower pH inside the cell interferes with the enzyme reactions and nutrient uptake, resulting in decreased growth rate and death of cells. The inhibition of lactic acid producing bacteria will lead to healthier yeast and higher ethanol yield.

- LactoStab® Controls Bacteria Naturally

Saccharomyces cerevisiae can often be a very delicate organism which needs care, protection and expertise to enable it to thrive. Unfortunately, the very conditions used to grow yeast are also attractive to contaminating bacteria. These contaminant bacteria can disrupt yeast production by causing competition for nutrients, flocculation and undesirable metabolites, such as dextran. This can stress the yeast and negatively impact on the yeast fermentation process as well as quality and performance standards.

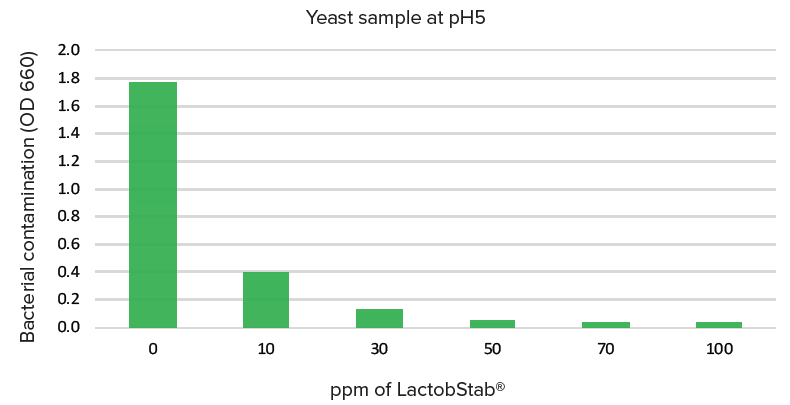

Reduction of Bacterial Contamination Using LactoStab®

- Performance Evaluation Results

BetaTec Hop Products have demonstrated the reduction of troublesome infections, such as Leuconostoc bacteria, on average by between 100 to 10000-fold (2 - 4 log). These results have been obtained in laboratory trials and also online yeast plants in day-to-day production. Removing such contaminants inevitably means easier downstream processing as well as enabling yeast the chance to display improved quality and performance, due to less stress from bacterial infection.

Packaging & Availability

- Packaging Type

- Packaging

- 20kg (5 gallon) pails

- 200kg (55 gallon) drums

- 1000kg (245 gallon) totes