Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Polymer Name

- Plastics & Elastomers Functions

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Materials Features

Applications & Uses

- Markets

- Applications

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

- Recommended Applications

- Components in food industry.

- Suitable for: Injection molding parts

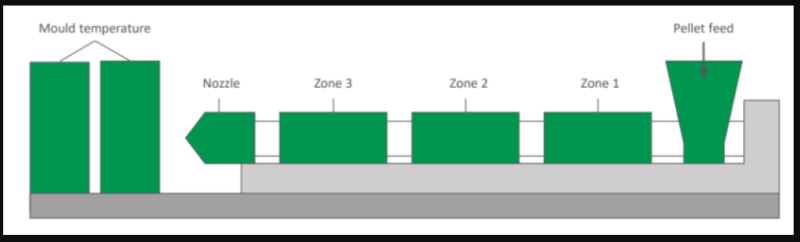

- Processing Temperatures

Grade Mold Temp. Nozzle Zone3 Zone2 Zone1 AKROMID® S3 8 natural (4881) 40-80°C 230-280°C 230-270°C 230-270°C 230-270°C

Properties

- Color

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Tensile Modulus (d.a.m.) | 2300 | MPa | ISO 527-2 |

| Charpy Notched Impact Strength (d.a.m.) | 4 | kJ/m² | ISO 179-1/1eA |

| Density | 1.08 | g/cm³ | ISO 1183 |

| Tensile Modulus (Conditioned) | 1200 | MPa | ISO 527-2 |

| Charpy Notched Impact Strength (Conditioned) | 12 | kJ/m² | ISO 179-1/1eA |

| Heat Distortion Temperature, HDT/A | 55 | °C | ISO 75/A |

| Humidity Absorption (70 °C, 62 % r.H.) | 1.7 | % | ISO 1110 |

| Melting Point | 220 | °C | — |

| Mold Shrinkage (flow/transverse) | 1.6/1.8 | % | ISO 294-4 |

| Renewable Content | approx. 60 | % | — |

| Strain at Break (d.a.m.) | min. 75 | % | ISO 527-2 |

| Stress at Yield (d.a.m.) | 65 | MPa | ISO 527-2 |

| Strain at Break (Conditioned) | min. 75 | % | ISO 527-2 |

| Stress at Yield (Conditioned) | 50 | MPa | ISO 527-2 |

| Drying time | 0 - 4 | hr | — |

| Drying temperature | 80 | °C | — |

| Processing moisture | 0.02 - 0.1 | % | — |

Regulatory & Compliance

- Certifications & Compliance

- Certification

- Food contact approval EU 10/2011