Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Polymer Name

- Plastics & Elastomers Functions

- Technologies

Features & Benefits

- Labeling Claims

Applications & Uses

- Applications

- Compatible Polymers & Resins

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

- Applications

- Designed to be compounded with other bio-based and biodegradable resins to form:

- NuPlastiQ BC Biodegradable/Compostable BioBlends for packaging and films

- CG 1000 can also be compounded with traditional fossil fuel based resins to produce:

- NuPlastiQ XP High Performance BioPolymers for packaging

- NuPlastiQ XD High Durability Polymers for durable goods

- The strength of CG 1000 can allow for significant downgauging, especially for thin film applications.

- CG 1000 maintains the compostability of the resin with which it is compounded

- CG 1000 has passed ASTM D6400 and EN-13432 and is certified to be industrial and home compostable by OK TUV.

- CG 1000 is certified to be marine biodegradable by OK TUV.

- CG 1000 is a USDA Certified Biobased Product.

- Thin films made with CG 1000 have a soft feel.

- Can be used as a stand-alone polymer for certain low temperature, injection molding applications.

- Supplied in pellet form.

Properties

- Color

- Mechanical Properties

- Physical Properties

- Thermal Properties

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Dart Impact Resistance | 3.5 | kg | ASTM D5628 |

| Elongation at Break | max. 10 | % | ASTM D638 |

| Tensile Strength at Break | min. 30 | MPa | ASTM D638 |

| Tensile Strength at Yield | min. 30 | MPa | ASTM D638 |

| Young’s Modulus | 1.5 | GPa | ASTM D638 |

| Value | Units | Test Method / Conditions | |

| Density | 1.4 | g/cm3 | ASTM D792 |

| Value | Units | Test Method / Conditions | |

| Glass Transition Temperature Tg | 50 - 70 | °C | Internal Method |

| Melt Flow Index (170 °C/21.6kg) | 6 | g/10 min | ASTM D1238 |

| Value | Units | Test Method / Conditions | |

| Water Content | max. 1.0 | % | ASTM D6980 |

Regulatory & Compliance

- Certifications & Compliance

- Chemical Inventories

Technical Details & Test Data

- Compostable Resin Blends

NuPlastiQ CG-1000 Masterbatch has been granted certification for both INDUSTRIAL and HOME composting by TUV.

Ok Compost INDUSTRIAL

With the OK compost INDUSTRIAL certification, customers who use NuPlastiQ resin to produce packaging or products can say that their product uses

materials certified for industrial compostability. This label guarantees that NuPlastiQ CG-1000 complies with the requirements set forth by ASTM

D6400 (2012) and EN 13432 (2000).Alternatively, if the customer wants to certify their product and feature the OK compost INDUSTRIALIlabel on their packaging, they must have their

product certifiedFortunately, due to NuPlastia's very rapid degradation rate, NuPlastiQ can enhance the overall biodegradation performance of other resins in applications where this is a desirable condition. For example, PBAT is often used as an agricultural mulch film; however, its degradation rate in a farm environment is slower than generally desired. Using a NuPlastiQ/ PBAT compostable blend, the degradation rate can be designed to be as short as 30-60 days, while still providing crop enhancing features that are required.

We have experience blending NuPlastiQ with a wide variety of other compostable resins such as PLA, PHA, PBAT, PBS and PCL. Please contact BioLogiQ directly to discuss your specific compostable resin material needs and we will help you design a compostable blend for your application.

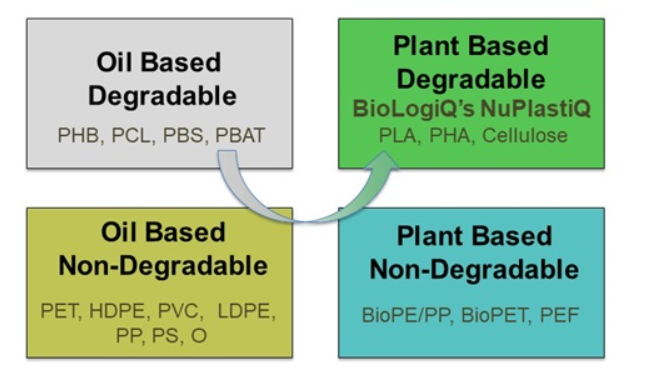

Conventional Plastics are shown in the top left quadrant. All three other quadrants are bioplastics.

Some bioplastics are not biodegradable (most are) and some fossil-fuel plastics are biodegradable (most are not). Any plastic that decomposes into natural elements because of microbial activity as verified by testing according to one of the ASTM test methods can be called and is considered to be biodegradable within the time limits and amounts as verified by the specific test method

Storage & Handling

- Storage and Drying

- Should be stored in a sealed container in a dry location away from heat.

- Delivered in a sealed container, pellets normally do not require drying prior to use. However, if left in opened containers, pellets should be dried to less than 1% moisture prior to processing. Drying of pellets can be performed by introducing warm, dry air at 60°C for 1-4 hours.