Knowde Enhanced TDS

Identification & Functionality

- CASE Ingredients Functions

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- CASE Ingredients Features

- Features

- Excellent defoamer

- Good compatibility

- Performs well over a wide range of pH values

- Successful at low concentrations

- Effective over a wide range of temperatures

- Helps with process productivity

Applications & Uses

- Applications

- Compatible Substrates & Surfaces

- Applications

- Gloss paints

- Wood coatings

- Pigment dispersions

- Matt and silk paints

- Dosage

- Borchi® Burst DF 300 is usually added as received. The amount required depends of course on the particular application. A typical addition level would be between 0.05% and 0.5% in total, depending on the severity of the foam problem. The optimum quantity and points of addition are determined by laboratory trials.

Properties

- Physical Form

- Appearance

- Pale yellow liquid

- Physical Properties

- Typical Properties

- Cleanliness

- No particles after screening through a 400μm aperture screen

| Value | Units | Test Method / Conditions | |

| Active Content | approx. 99 | % | - |

| Fluidity (at 20°C, 100rpm) | Viscosity max. 2000 | cPs | DIN 53019 |

| Specific Gravity (at 20°C) | 0.98 - 1.02 | g/ml | - |

| Water Miscibility | Medium dispersibility | - | - |

| Value | Units | Test Method / Conditions | |

| Solid Content | 100 | % |

Technical Details & Test Data

- Efficacy Studies

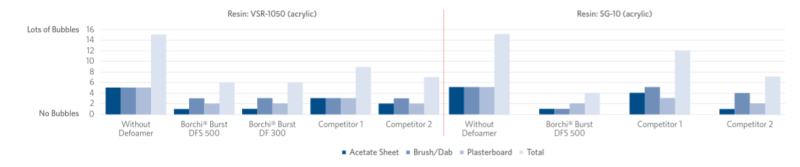

High-performance defoaming across multiple substrates and applications.

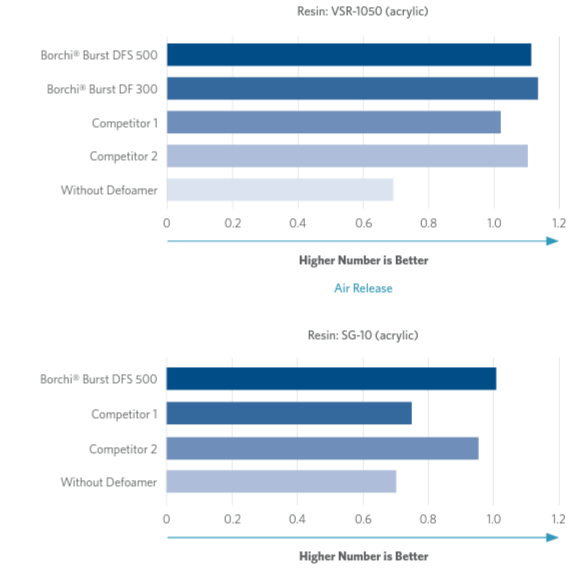

Borchi® Burst 500 and 300 eliminate both micro and macro air bubbles upon different methods of application and across multiple resins.

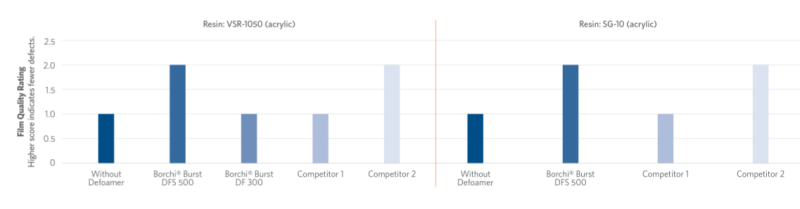

Excellent compatibility and robustness across multiple resins and coating technologies

Compatibility compares the number of film defects observed after applying paint on a glass plate (wet film: 100-150 pm) and visually comparing it to a blank sample (without defoamer).

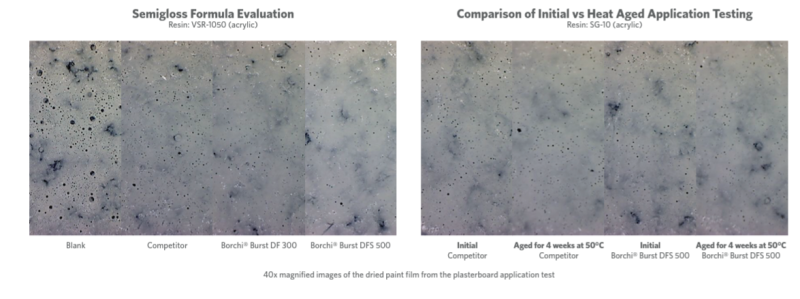

No loss of efficiency with Borchi® Burst 500 over time at 50°C for 4 weeks in a high quality 100% acrylic formula.

40x magnified images of the dried paint film from the plasterboard application test.

Superior Air Release (Spin Test)

Safety & Health

- Safety

- Please refer to our safety data sheet for information relating to product safety.

Packaging & Availability

- Regional Availability

Storage & Handling

- Storage

- Store in closed containers. Avoid extremes of temperature, keep between 5°C and 30°C. Avoid freezing and do not store in direct sunlight. Product has a shelf life of 12 months, however during this time period some phasing may occur. Remixing will ensure the product is suitable for use.