Knowde Enhanced TDS

Identification & Functionality

- Backing Material Type

- Chemical Family

- Product Type

- Technologies

Features & Benefits

- Ready-to-Use Product Features

- Advantages

- Fire classification B-s1, d0 according to EN 13501*

- High tear resistance

- Workable at cold temperatures

- Very good adhesion even at low temperatures

- Very good resistance to high temperatures

- Waterproof and self-sealing

- Resistant to aging and UV radiation

- Solvent-free

Applications & Uses

- Markets

- Applications

- Application Area

- Application

Alubutyl FR was developed for use in the construction sector where properties such as flame resistance and weather resistance are particularly important.

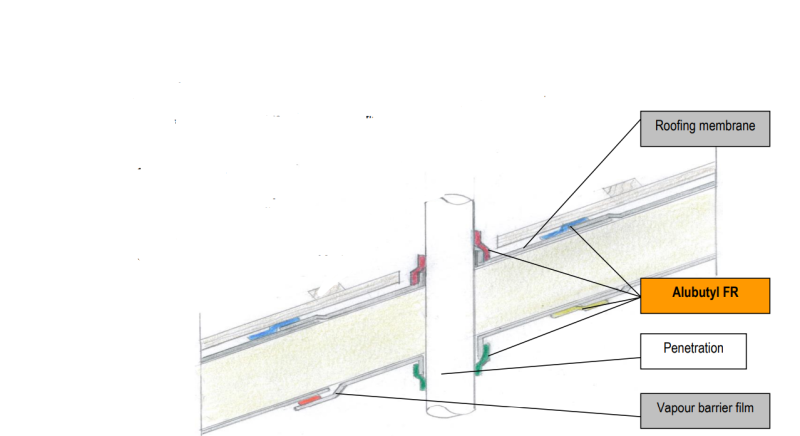

Seals in the roof area:

- Of ridge tiles

- Of chimneys

- Of joints on glass roofs

- Of formwork in the valley area

- Repair of gutters and drain pipes

- Bonding of vapor brakes and barriers

Seals in the façade area

- Of door and window connection joints

- Of verandas

- Of winter gardens

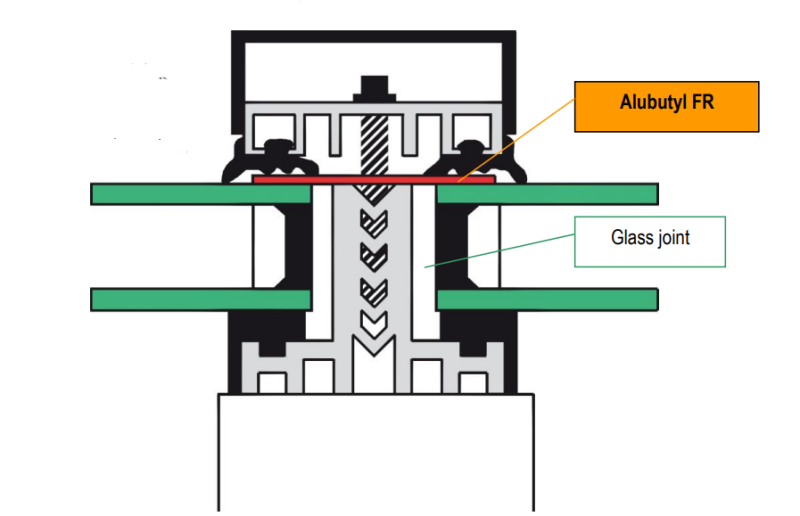

- Sealing of glass joints in metal construction

Pipe cladding in the industrial / sanitary / air conditioning sector:

- Of heat insulated pipes

- Of pipes for air conditioning

- Of pipes for ventilation systems

- When used to seal against water, the possibility of standing water on the sealing tape must be ruled out.

- Processing

- Alubutyl FR is very suitable for use on the following substrates: All common substrates in construction, especially concrete and plasters with hydraulic binders, bricks, metals, especially aluminum, wood treated with water-based paints, raw planed and/or sanded wood, hard PVC, plexiglass, polycarbonate, glass. The user must ensure that the adhesive is compatible with the surface in terms of adhesive strength, colors and chemicals (carry out your own tests). The surface must be clean, smooth, dry, free of oil, grease and dust and inherently firm, stable and secure. Porous and absorbent substrates must be pre-treated with the Multi Primer. If you want to use Alubutyl FR to replace bituminous adhesive tapes, the surface must be cleaned of all bitumen residues.

- Traces of grease must be removed with a suitable solvent. Partially remove the cover film from the adhesive layer on the back and press on Alubutyl FR. After fixing in place, continue to peel off the cover film and press the product firmly in order to avoid the formation of air bubbles. To avoid tension and the possible loss of adhesive strength, ensure that Alubutyl FR molds to the contours of the substrate. After installation, press Alubutyl FR firmly onto the surface (use pressure roller). Processing at 0 to 5 °C reduces the initial adhesive strength. Although application will be possible at such temperatures, longer contact times will be required before the high ultimate strength is reached. In the case of joints, there must be an overlap of at least 5 cm. Alubutyl FR can be painted over with suitable colors (carry out your own tests).

- Butyl tapes are inherently plastic and have no elastic properties. They are not suitable for permanent heavy mechanical loads and cannot replace the use of assembly adhesives or mechanical fasteners. The mechanical strength of butyl rubber adhesives decreases with increasing temperature. Adhesive tapes with butyl rubber adhesive are sensitive to solvents.

Properties

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Tear Resistance | 185.0 | N/50 mm | — |

| Elongation At Break | 20.0 | % | — |

| Solids Content | 100.0 | % | — |

| Shear Strength | 27.0 | N/ cm | ASTM D 1000 with 180° peel |

| Initial Adhesion | 7.0 | N | ASTM D 2979 |

| Fire Behaviour | class B-s1, d0* | — | EN 13501-1 /EN 11925-2 |

| Water Vapour Permeabilit | 2720000.0 | — | EN 1931 |

| Voc Emissions | 30.0 | ug/m² | ISO 16000-6 |

| Processing Temperature | 5 - 30 | °C | — |

| Temperature Resistance | -30 to 90 | °C | — |

| Thickness | approx. 0.8 | mm | — |

| Roll Length | 10.0 | m | — |

| Width | 10 - 1000 | mm | — |

Safety & Health

- Safety

Keep out of the reach of children.

Storage & Handling

- Storage

- 12 months after the date of manufacture in the closed original container at temperatures from +5 °C to max. +30 °C, protected from moisture.

- The storage location must be properly ventilated. The masking paper tends to stick to the butyl adhesive if the storage temperature exceeds 30 °C. Alubutyl FR is not sensitive to frost.