Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Product Type

- Technologies

- Product Families

Features & Benefits

Applications & Uses

- Applications

- Application & Uses

Applications

- Flexible or Rigid Substrates, Moving or Stationary Parts, Impact Zones

- CLS-4000 is an industry proven technology for joining dissimilar materials using a high strength structural aerospace epoxy. By employing this technology for abrasion resistant applications the resulting bond strength, increased impact strength and wear resistance material options are unmatched in the industry.Applications range from dynamic components like fans, rotors, screw conveyors and airlocks to stationary parts like chutes, hoppers, fan housings and wear panels where guaranteed bond performance is a must.

- CLS-4000 vacuum bonding technology provides opportunities to extend equipment life, reduce component weight and provide wear solutions for even the most complicated shapes. Deploying this technology over a wide range of industries has provided our customers money saving opportunities to refurbish old equipment, install wear panels only where needed and reduce downtime by relying on a wear resistant product they can count on.

- CLS-4000 products can withstand temperatures up to 350°F and with bond shear strengths exceeding 5,000 PSI.

Where CLS-4000 should be used?

- Dynamic applications like fans, rotors, screw conveyors and airlocks.

- Applications where ceramic and tungsten wear materials are required and surfaces need to be machined, ground or honed to exacting tolerances.

- Power Plants: Exhauster Fans, Bullnose, Roof Liners, Feeder Transitions, Multi-Ports, Classifier Cones, Impact panels for coal chutes, Diverter Gates.

- Grain: Spouting, Screws, Troughs, Transfer Chutes, Airlocks.

When should CLS-4000 be used?

- Other adhesions methods have failed.

- Greater impact resistance is needed.

- Abrasion material loss could possibly damage other equipment.

- Applications where component weight is an issue compared to chromium carbide overlays, hardened steels or castings. Ceramic is approximately half the weight of steel and can lessen the load on motors, supports, gears, bearings, etc.

- Complicated shapes require an abrasion resistant lining.

- Vacuum bonding should be used primarily on dynamic parts that require extra bond strength due to centrifugal forces. The vacuum bonding application boasts many benefits beyond combating centrifugal forces such as impact resistance (quantification to come).

Why should CLS-4000 be used?

- CLS-4000 provides the highest bond strength and improves impact resistance on alumina ceramic and tungsten materials commonly used for severe abrasion applications

- Provides component flexibility

What is CLS-4000 Technology?

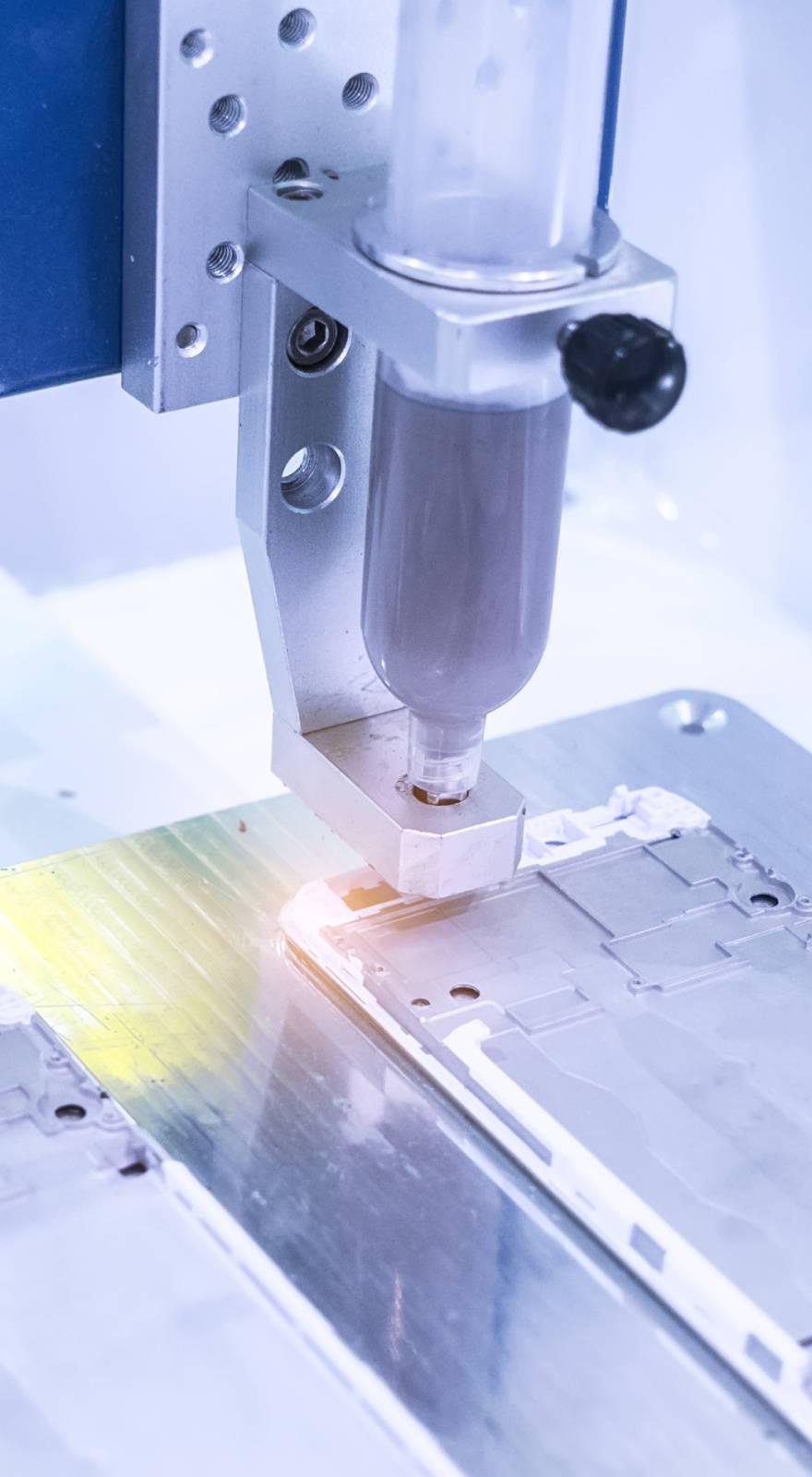

CLS-4000 is more commonly known as vacuum bonding where materials are joined with a high strength structural epoxy while under heat and pressure

Installation

CLSI Shop Only

Properties

- Adhesion

- Best

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Operating Temperature | 350.0 | °F | — |

| Conditions | Wet or Dry | — | — |

| Applications | Flexible or Rigid Substrates, Moving or Stationary Parts, Impact Zones | — | — |

| Installation | CLSI Shop Only | — | — |

| Lap Shear Bond Strength | min. 5000 | psi | — |