Knowde Enhanced TDS

Identification & Functionality

- Base Oil Type

- Product Type

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

- Features and Benefits

5% Liquid, Usually for Production Applications, Flushing Action, Prevents Over Application of DeoxIT®, Safe on most Plastics.

DeoxIT® Shield S100L concentrate has 0.0% chemical cleaning action.

Ideal for severe environments (humidity, salts, pollutants, sulfur, etc.)

Excellent protection, good conductivity enhancing, excellent lubrication.

Creates a long lasting barrier against oxidation and corrosion.

No ozone depletion.

Reduces intermittent connections, arcing, RFI, wear and abrasion.

Cleaner Audio - Clearer Video - Reliable Data.

Applications & Uses

- Applications

- Application Area

- Compatible Substrates & Surfaces

- Formulation

5% DeoxIT® Shield S100L

20% 1,1,1,3,3-PENTAFLUOROPROPANE (460-73-1)

75% odorless mineral spirits (64742-88-7)- Which DeoxIT® Product do I Use

- Use DeoxIT® D-Series contact cleaner on surfaces that have been in service or have visual signs of oxidation. Contains 20% active cleaner.

- Use DeoxIT® Gold G-Series conditioner on new surfaces, and gold plated surfaces. Ideal for preventing dendrite/fretting corrosion. Protects both surface and base metals. Ideal for critical applications. Contains >1% active cleaner.

- Use DeoxIT® Shield S-Series to protect surfaces from severe environments (humidity, salts, pollutants, sulfur, etc.). Use on clean surface. Contains 0% active cleaner.

- Directions for Use

1. Turn o_x001f_, unplug the device.

2. On surfaces that have been in service or have visual signs of oxidation or corrosion pre-treat with DeoxIT® D-Series contact cleaner or other cleaning process (ultra-sonics). Components, contacts and connectors may appear to be clean; however, they may have slight oxidation on the surfaces. When in doubt, _x001e_rst clean with DeoxIT® D-Series. You do not want apply DeoxIT® Shield S-Series over dirty/oxidized metal surfaces.

3. Apply DeoxIT® Shield S-Series contact protector to contact/connector metal surfaces.

4. Operate the part/device to help distribute the DeoxIT® Shield. Apply one more short burst. Wait two minutes before turning on equipment. Test for compatibility before use.

5. For extended protection: For severe environments (humidity, salts, pollutants, sulfur, outdoor applications, etc.) and to apply an additional environmental barrier, apply one of the DeoxIT® Greases. See Data Sheets DS-L260 and DS-M260 for additional information;

6. For production applications, contact a CAIG representative for information and/or recommendations.- Other Applicators

Part No. % DeoxIT® VOC (%) Applicator Size Flammable/Non FlammableS5S-6 5% 75% spray 163 g Flammable SN5S-6N 5% 0% spray 163 g Non Flammable SN5S-2N 5% 0% mini-spray 40 g Non Flammable S100S-2 100% 0% spray 57g Non Flammable S100P 100% 0% pen 6 mL Non Flammable S100L-P6C 100% 0% oiler pen 6 mL Non Flammable S50W 100% 0% wipes 50 count Non Flammable S1W 100% 0% wipes individual Non Flammable S100L-2C 100% 0% tube 2 mL Non Flammable S100L-2DB 100% 0% brush bottle 7.4 mL Non Flammable S100L-25C 100% 0% needle dispenser 25 mL Non Flammable S100L (bulk, many sizes) 100% 0% bottle/drum assort. Non Flammable

Regulatory & Compliance

- Regulations

VOC (%): Part No. S5L-A, 75% (588 g/L)

RoHS Compliant: Yes

VOC Compliant: Yes

Technical Details & Test Data

- Materials Compatibility

(Rating: Not compatible, Poor, Fair, Good, Excellent), (N/A = Not applicable (no solvents and propellants)

(* If the product is not 100% DeoxIT® then the package is rated before and after the solvents/propellants are applied to materials. Compatibility testing is always recommended)Material Name Rating (*100% DeoxIT®) Rating (*with solvents)ABS Excellent Fair-Good Nylon Excellent Excellent Lexan Excellent Excellent HDPE Good Good LDPE Good Good C.E.Phenolic Excellent Good Epoxy Excellent Excellent Polycarbonate Excellent Fair-Good PMMA Fair Poor POM Excellent Excellent PP Excellent Good PS Fair Fair PTFE Excellent Excellent PVC Excellent Excellent TPE/Rubber/Varnish Poor Poor Important:

Rating, 100% DeoxIT®: Any of the above that fall into the “Fair” and “Poor” categories should be thoroughly tested for compatibility. They may be compatible, however, it will depend on the manufacturing process of the materials. Acrylics, ABS, and polycarbonate, if under stress, may show slight cracking or crazing damage. Test for compatibility before use. On porous materials; i.e. wood, rubber, cloth, some phenolics, semi-cured materials, no liquid or solvents should be used. Occasionally, DeoxIT® will get onto unwanted surfaces, quickly wipe o_x001f_ surface and usually no damage will occur.

Rating, with solvents: Similar to rating above (100% DeoxIT®). However, any rating worse than the 100% DeoxIT® may require additional care. If DeoxIT is applied to unwanted areas or materials, wipe o_x001f_ surface quickly and usually no damage will occur. Alternatively, apply DeoxIT® onto a lint-free swab or cloth _x001e_rst and then wipe onto desired metal surface.- Product Selection Guides

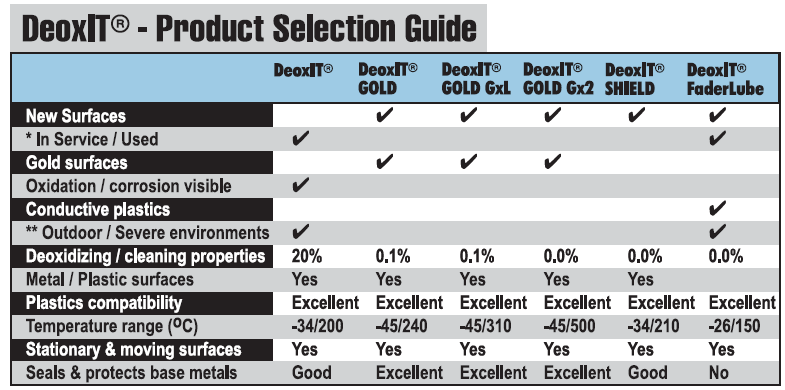

All products are Nonflammable and RoHs Compliant

*In Service: Clean with DeoxiTo. For added protection, follow with DeoxlTo GOLD (indoors), DeoxlTo

SHIELD (outdoors) or DeoxlT° Grease (additional barrier).

**Severe environments: Pre-clean with DeoxlTo. Follow with DeoxlTo SHIELD or DeoxlTo Grease.

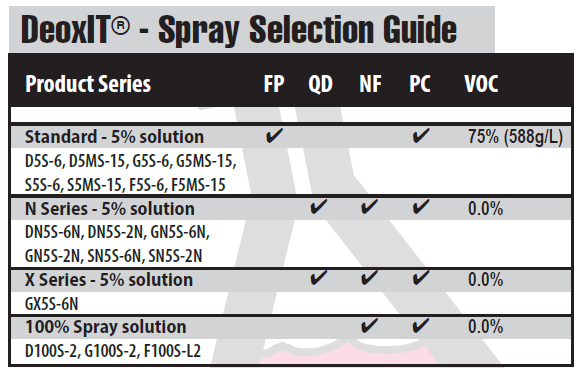

FP = Flushing properties QD = Quick dry / non drip

NF = Nonammable PC = Plastics compatibility VOC = VOC (%)

Packaging & Availability

- Part Numbers

- S5L-25CA (25 mL squeeze bottle)

- S5L-4A (118 mL, coated bottle)

- S5L-32A (944 mL, container)

- S5L-55GA (55 gal., drum)

Storage & Handling

- Shipping

Hazardous: ORMD