Knowde Enhanced TDS

Identification & Functionality

- Carrier

- Chemical Family

- Cosmetic Ingredients Functions

- Technologies

- Product Families

Features & Benefits

- Benefit Claims

- Labeling Claims

- Product Background

For more than 100 years, Penreco® has specialized in niche product blending to meet customer specific requirements. If you are interested in finding out more about the many attributes of our gelled technology, we can provide supporting clinical studies. Please contact your Penreco sales representative and our technical experts will be happy to find a solution that’s right for you.

- Versagel Features

Versagel technology is used in thousands of cosmetic, pharmaceutical and personal care products around the world. Our innovative patented system for thickening and gelling hydrocarbon materials offers an infinite number of customized rheological properties.

- Clear, colorless (does not discolor with age), hydrophobic, thermally reversible and without syneresis.

- Creates a film barrier for added moisturization, delivers superior stabilization and suspension properties.

- Available in multiple viscosity ranges and compatible with many common ingredients.

- Easier and safer than gels made using metal stearates or fumed silica.

- Provides enhanced fragrance retention and waterproofing properties.

Applications & Uses

- Markets

- Applications

- Color Cosmetic Applications

- Hair Care Applications

- Personal Hygiene Applications

- Skin Care Applications

- Applications

- Color Cosmetics: mascara, eyeliner, lipstick, eyeshadow, face/body paint, blush, bronzer, foundation, setting lotions and primers, body glitter

- Skin Care: serums, gels, oils, lotions, creams, scrubs, balms, makeup remover, hand cleaners

- Sun care

- Fragrances

- Hair Care: serums, oils, styling products, conditioners, creams

- Soap and Bath Products

- Pharmaceuticals/Nutraceuticals

- Healthcare

Properties

- Physical Form

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Saybolt Color | 23+ | — | ASTM D156 |

| Flash Point | min. 45 | °C | ASTM D92, D93 |

| Specific Gravity (at 25/25 °C) | 0.7486 | — | ASTM D4052 |

| Viscosity (at 25 ˚C) | 20,000 - 35,000 | cPs | ASTM D2983 |

| Polarity LOG P | 6.2 | — | — |

Technical Details & Test Data

- Hydrocarbons, Esters and Natural Hydrocarbons

Versagel products are used in a wide variety of formulations. Product properties such as texture and phase stability depend on several factors like the Versagel used, it’s viscosity, other formulation ingredients, relative amounts of all ingredients, order of addition, and other formulation variables. The calculated Log P (Mol Inspiration) can be used to compare the relative polarity of each Versagel. We hope that formulators find these Log P values helpful when deciding which Versagel to incorporate into their formulations. In general, the non-polar Versagel products have higher Log P values and should mix well with non-polar formulation bases. Surfactants and emulsifiers enable mixing of polar and non-polar substances so they can have a significant impact on formula stability when utilized.

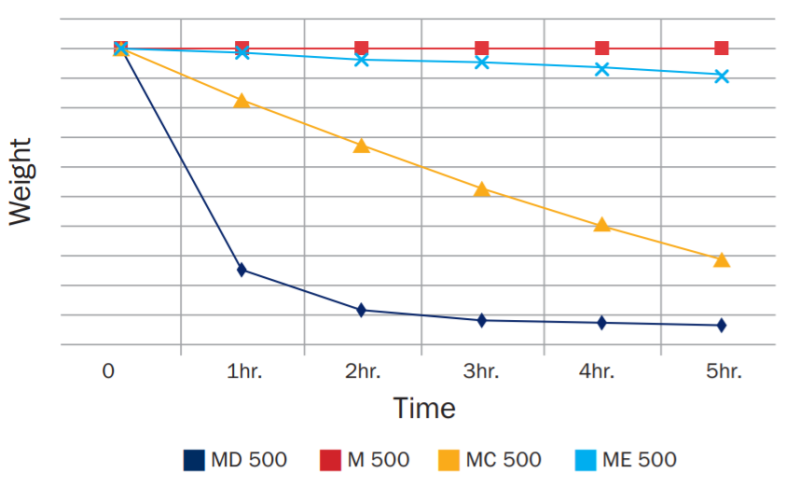

- Volatility Comparisons

Among the Versagel product lines, Versagel MD has the greatest volatility. The graph illustrates the volatility differences among Versagel MD, MC, ME and M products. Versagel MD 500 loses 75% of its weight in the first hour, versus 18% for MC 500 and 1.6% for ME 500 at elevated temperatures (90 °C).