Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Chemical Name

- CASE Ingredients Functions

- Cleaning Ingredients Functions

- Fluids & Lubricants Functions

- Industrial Additives Functions

- CAS No.

- 8042-47-5

- EC No.

- 232-455-8

- Technologies

- Product Families

Features & Benefits

- CASE Ingredients Features

- Fluids & Lubricants Features

- HII Features

- Industrial Additives Features

- Product Highlights

- Penreco® has developed a unique system for thickening and gelling hydrocarbons. With an infinite number of customized rheological properties available, these Synergel products are clear, colorless, hydrophobic, thermally reversible, and without syneresis.

- Synergel products are available in multiple viscosity ranges and are compatible with many ingredients. Synergel products are visually appealing and do not discolor with age. They are easier and safer to formulate with than gels that use metal stearates or fumed silica and they provide fragrance retention and waterproofing properties.

- Benefits of Synergel with Formulations

Versatility

- Compatible with a wide variety of low polarity ingredients

- Broad range of viscosity profiles that don’t change over time

- Ease of incorporation in post batch modifications

Performance

- Strength and durability

- Enhanced lubrication

- Excellent flexibility and crack resistance

- Exceptional product and emulsion stability

Stability

- Self-preserving formulation base

- Resists growth/proliferation of microorganisms

- Heat processed & micro-filtered

- No harsh chemicals and low toxicity

Cost Effective & Formulation Friendly

- Reduces the amount of structural material required to make a formulation

- No child-resistant packaging required

- Easy to use with a high level of formulation processability

- Efficient delivery system

Applications & Uses

- Applications

- Applicable Processes

- Application Method

- Fluids & Lubricants Type

- Fluids & Lubricants End Use

- Home Care Applications

- I&I Cleaning Applications

- Applications

- Automotive Products

- Ballastics/Firearms

- Chemical Processing

- Coatings

- Degreasers

- Fishing Bait

- Hand Cleaners

- Household and Industrial Cleaners

- Lighter Fluid

- Metal Rolling Oils

- Metalworking

- Mineral Seal Oils

- Paints

- Polishing

- Printing Ink Oils

- Pyrotechnics

- Solvents

- Spray Furniture Polish

- Spray Paint

- Strippers

- Water Treatment Chemicals

Properties

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Flash Point | min. 300 | ˚F | ASTM D92, COC |

| Saybolt Color | min. 27 | — | ASTM D156 |

| Specific Gravity (at 25 ˚C) | 0.843 | — | ASTM D4052 |

| Viscosity (at 25 ˚C) | 47,000 - 57,000 | cPs | ASTM D2983 |

| Base Material (Vis White Oil) | 70 | — | — |

Regulatory & Compliance

- Certifications & Compliance

- Quality Standards

- Regulatory & Compliance

All Synergel products are processed in a segregated and dedicated area of a FDA Registered Drug Establishment. However, Synergel products are NOT food/pharmaceutical grade products.

- FSSC 22000 (GFSI)

- cGMP standards

- USP Testing capability

- State Dept. of Health registration

- ISO 9001:2015

- Kosher OU

- FDA Registered Drug Establishment

Technical Details & Test Data

- Mineral Oil - Based

- The Synergel white oil based products are based on gelling USP/NF grade white mineral oil in such a way as it promotes superior moisture retention by creating a continuous film enabling oil to be easily spread with no pooling of the product. It also provides a low moisture system for protection of water sensitive additive packages/ingredients.

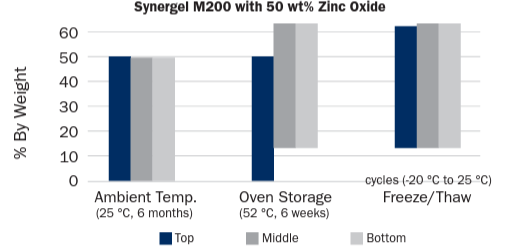

- In liquid systems fine particles don’t easily remain in suspension and tend to settle at the bottom and agglomerate. As shown below in the suspension stability testing Synergel provides excellent suspension properties as the polymers act as additional dispersants and prevents movement.

- For applications where optical clarity is required, Synergel products retain the sparkling transparency of the starting hydrocarbon fluid. The high clarity/water white base material allows the customer to tailor/tint products for a custom color esthetic.

- Technical Comparison of Gelled Mineral Oil with Mineral Oil Alone

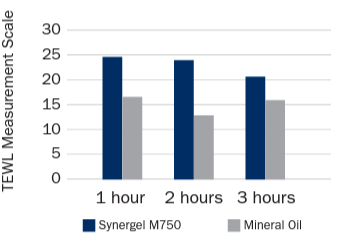

Moisturization

The TEWL test shows gelled mineral oil moisturization improves by 53% compared to mineral oil alone. Using a gelled product in a final formulation can aid in prevention of moisture loss ie. “reconditioning” properties for porous materials, such as furniture.

Suspension Stability

No change in suspension capabilities under test conditions. Gelled mineral oil maintains suspension of active ingredients at a very high load.