Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- CASE Ingredients Functions

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

Applications & Uses

- Applications

- Cure Method

- Coating Type

- Applications

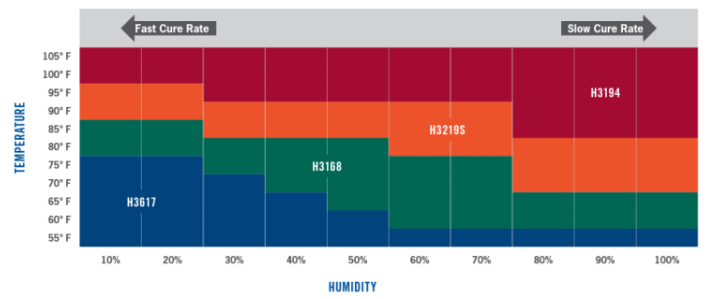

Tru-Motion H3617 is a 100% solids, aliphatic isocyanate based, moisture cure binder for use in construction of bonded rubber granule type running tracks, athletic and safety surfaces.

- Processing

Under normal conditions of installation, Tru-Motion H3617 binder for granular rubber athletic surface products provides excellent work life while achieving sufficient cure for secondary processing within normal construction cycles. Tru-Motion H3617 binder for granular rubber athletic surface products is designed to cure by reaction with atmospheric moisture. Cure rate is accelerated by high humidity and temperatures and retarded by low humidity and temperatures. Under conditions of high temperature and low humidity, water misting of the applied surfaces immediately after installation will prevent the Tru-Motion H3617 from draining off the granular rubber components. Tru-Motion H3617 as supplied has a work life suitable for use in safety surfaces under conditions of low temperature and low humidity.

Caution : Any colored EPDM granule mixture used with Tru-Motion H3617 should be evaluated for color change and reactivity rate before installation. Bromine will discolor all installed PIP surfacing.

Properties

- Appearance

- Light yellow viscous fluid

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Density | 8.6 - 8.9 | lbs./Gal. | - |

| Viscosity | 3,000 - 5,000 | cps | - |

| Free NCO | 7.0 - 8.2 | % | - |

| Tensile Strength | 2700 - 3300 | psi | ASTM D 412 |

| Elongation | 450 - 550 | % | ASTM D 412 |

| Die C Tear | 234 - 286 | pli | ASTM D 624 |

| Split Tear | 50 - 60 | pli | - |

Technical Details & Test Data

- Tru-motion Aliphatic Binder Temperature/Humidity Chart

Safety & Health

- Safety and Handling

- Wear proper protective equipment at all times.

- Tru-Motion H3617 is a primary skin irritant and can cause sensitization dermatitis. Avoid contact with skin and eyes.

- Wear proper protective equipment at all times when handling Tru-Motion H3617.

- In the event of eye contact, flush eyes thoroughly with water and seek medical attention.

- Pressure can build up in new and previously opened containers, open all containers carefully.

- Protect open containers from moisture.

- Dispose of contaminated materials and empty containers in accordance with Federal, State and Local regulations

Packaging & Availability

- Packaging

Tru-Motion H3617 is available in 55-gallon closed head drums with a net weight of 450 lbs. and 5-gallon pails with a net weight of 43 lbs. Returnable and one-way 250-gallon mini-bulk containers are available on a special order basis.

Storage & Handling

- Storage

Tru-Motion H3617 should be stored in cool, dry surroundings. Avoid prolonged storage temperatures over 90° F or below 40° F. Under conditions of proper storage, storage life of the product in original, factory sealed containers is 3 months.