Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Chemical Name

- CAS No.

- 9082-00-2

- Technologies

- Product Families

Features & Benefits

- CASE Ingredients Features

Applications & Uses

- Applications

- Recommended Applications

- Coatings

- Sealants

- Potting Compounds

- Adhesives

- Elastomers

Properties

- Physical Form

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Approximate Functionality | 3.0 | - | - |

| Moisture Content | max. 0.04 | % | — |

| Approximate Molecular Weight | 700.0 | Da | - |

| Average pH | 7.0 | - | - |

| Color APHA (Max) | 35.0 | - | - |

| Density at 25 °C | 8.36 | lb/gal | - |

| Hydroxyl Number | 240.0 | mg KOH / g | - |

| pH (10 parts of IPA: 6 parts of H2O) | 7.0 | - | - |

| Potassium Content (max) | 5.0 | ppm | - |

| Renewable Content | 44119.0 | % | - |

| Viscosity at 25ºC | 250.0 | cP | - |

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

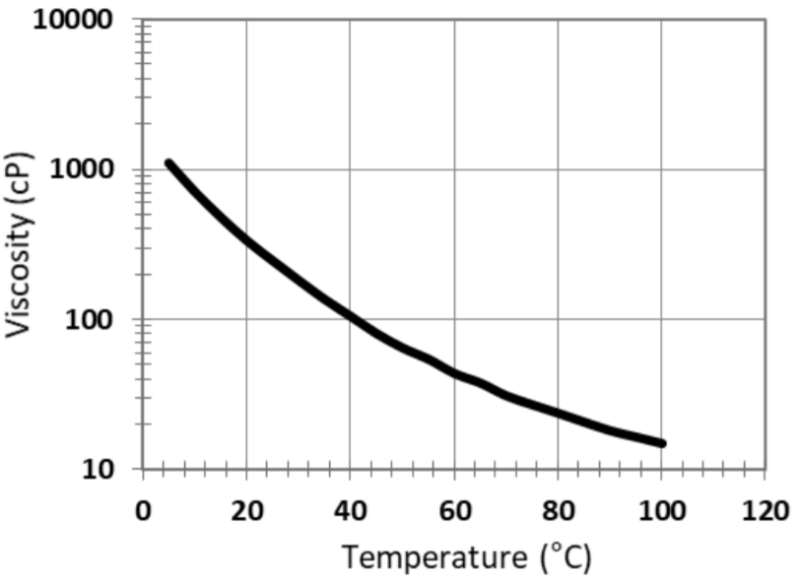

- Viscosity Profile

Packaging & Availability

- Packaging Type

- Packaging Information

-

Sample Sizes

- 1 quart

- 1 gallon

- 5 gallon

-

Availability

- Totebin 2,300 lb net wt.

- Drum 460 lb net wt.

- Tankwagon 40,000-45,000 lb net wt.

- Railcar 185,000-189,000 lb net wt

-

Storage & Handling

- Handling and Storage

CARPOL® GP-725 will absorb water if the product container is not secured properly. This may affect reactivity, appearance, and performance. Therefore, it is advised that all receptacles containing this material be tightly fastened and stored in a dry place. Consult the Safety Data Sheet for additional information.