Knowde Enhanced TDS

Identification & Functionality

- Product Type

- Technology

- Cyanoacrylate / UV / Visible

- Chemistry

- Alkoxyethyl Cyanoacrylate with photoinitiator

- Components

- One part requires no mixing

- Viscosity

- Gel - like

- Cure

- Ultraviolet (UV) light

- Secondary Cure

- Humidity

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

Applications & Uses

- Applications

- Cure Method

- General Information

This product is not recommended for use in pure oxygen and/or oxygen rich systems and should not be selected as a sealant for chlorine or other strong oxidizing materials:

Directions for use:

1) This product is light sensitive; exposure to daylight, UV light and artificial light should be kept to a minimum during storage and handling.

2) For best performance bond surfaces should be clean and free from grease.

3) This product performs best in thin bond gaps (0.05 mm)

4) Excess adhesive can be dissolved with nitromethane or acetone.

Properties

- Color

- Physical Form

- Appearance

- Transparent, yellow liquid

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Specific Gravity (25°C) | 1.13 | g/cm³ | |

| Viscosity, Brookfield DVNXRVCJG, (25 °C) (Spindle 52, 0.3 rpm) | 30000 to 60000 | mPa. s |

Technical Details & Test Data

- Typical Curing Performance

TACK FREE TIME

Tack Free Time is the time in seconds required to achieve a tack free surface.

UV/Visible Light Sources:

Electrodeless, V bulb:

70 mW/cm2, measured @ 365 nm: < 10 s.

Electrodeless, H bulb:

30 mW/cm2, measured @ 365 nm: < 10 s.

100 mW/cm2, measured @ 365 nm: < 10 s.

Visible Light Sources:

Blue light laser:

70 mW/cm2, measured @ 445 nm: < 10 s.

CURE SPEED vs. SUBSTRATE (non-UV/Vis cure)

The rate of cure will depend on the substrate used. The table below shows the fixture time achieved on different materials at room temperature. This is defined as the time at which an adhesive bond (250 mm 2 ) is capable of supporting a 3 kg load for 10 seconds. Fixture time measurements relate to non UV/Visible cure.Fixture Time (seconds) ABS 15 Acrylic 90 Polycarbonate 40 PVC 150 - Typical Performance Of Cured Material

TENSILE SHEAR STRENGTH

The shear strength will depend on the substrate. The Table below shows the shear strength for different substrates using lap shears according to ISO 4587. Data for 24-h curing in dark room and 10-second curing with UV/Vis light source.Strength (N/mm )2 After 24 h RT Non UV/Vis cure Strength (N/mm 2) After 10 s curing with UV/Vis lightABS 12.7* 7.3* Acrylic 6.6* 8.3* Polycarbonate 11.9* 6.2* PVC 6.5* 3.6 - Conversions

(ºC x 1.8) + 32 = ºF

kV/mm x 25.4 = V/mil

mm / 25.4 = in

μm / 25.4 = mil

N x 0.225 = lb

N/mm x 5.71 = lb/in

N/mm2 x 145 = psi

MPa x 145 = psi

N·m x 8.851 = lb·in

N·mm x 0.142 = oz·in

mPa·s = cP- Chemical/Solvent Resistance

Aged under conditions indicated and tested @25℃

% of initial strength Environment Temp. ℃ 100 hrs 500 hrs 1000 hrs Water 25 84 69 50 Ethanol 25 94 89 88 Isopropanol 25 106 103 100 Water/Glycol 25 100 95 96 Unleaded Gasoline 25 89 93 81 Motor Oil 25 103 97 100 98% Relative Humidity 40 83 72 66 Aged under conditions indicated and tested @25℃

Lap Shear Strength, ISO 4587/ASTM D1002/JIS K6850

PC (Polycarbonate)% of initial strength Environment Temp. ℃ 100 hrs 500 hrs 1000 hrs Air 25 103* 98* 101* 98% Relative Humidity 40 97* 89* 74 - Typical Environmental Resistance

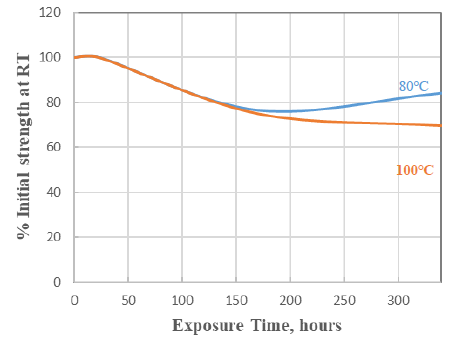

Heat Aging

Cured @ 30 mW/cm2, measured @365nm, for 10 seconds plus 24 hours post cure @22℃. Aged at temperature indicated and tested @22℃.

Safety & Health

- Precautions

1. Avoid contact with skin and eyes.

2. If contact with skin, rinse with water.

3. If adhesive gets into eye, keep eye open and rinse with water thoroughly. Seek medical attention immediately.

4. Keep the material out of children’s reach.

Storage & Handling

- Storage

Keep adhesive in a cool and dry place. The storage temperature is recommended at 8 °C - 24 °C. Shelf life is twelve months from the date of manufacture in the original container under the optimal conditions.