Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Technology

- Acrylic

- Chemical Type

- Methacrylate ester

- Components

- One component – requires no mixing

- Viscosity

- Medium

- Cure

- Anaerobic

- Secondary Cure

- Activator

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

Applications & Uses

- Applications

- Application Area

- Compatible Substrates & Surfaces

- General Information

This product is not recommended for use in pure oxygen and/or oxygen rich systems and should not be use with chlorine or other strong oxidizing materials. Where washing systems are used to clean the surfaces before bonding, it is important to check the compatibility of the washing solution with the adhesive. In some cases, these solutions can affect the cure and performance of the adhesive. This product is not recommended for use on certain plastics. Users are recommended to confirm compatibility of the product with such substrates.

- Directions For Use

For assembly

1. The substrate surfaces must be clean and free of grease.

2. Shake the product thoroughly before use.

3. If the cure speed is too slow, consider using activator.

4. Apply several drops to the nut & bolt.

5. Assemble and tighten as required.

6. To prevent the clogging of the bottle nozzle, do not let the tip touch the metal surfaces during application.

For disassembly & cleanup

1. Use localized heat (250 ℃) to nut and bolt, disassemble while hot.

2. Use a wire brush to clean the charred product.- Applications

Thread sealing

Properties

- Physical Form

- Appearance

- Purple liquid

- Typical Properties

- Adhesive Properties

| Value | Units | Test Method / Conditions | |

| Specific Gravity (25°C) | 1.1 | g/cm³ | — |

| Viscosity, Brookfield - RVT (25°C) (Spindle 3, 2.5 rpm) | 9,000 to 20,000 | mPa·s (cP) | — |

| Value | Units | Test Method / Conditions | |

| Breakaway Torque (M10 steel nuts and bolts) (Cured for 24 hrs at 25 °C) | 22.0 | lb.in | ISO 10964 |

| Breakaway Torque (M10 Zinc dichromate nuts and bolts) (Cured for 24 hrs at 25 °C) | 14.0 | lb.in | ISO 10964 |

| Prevail Torque (180°) (M10 steel nuts and bolts) | 0.9 | lb.in | ISO 10964 |

| Prevail Torque (180°) (M10 Zinc dichromate nuts and bolts) | 4.0 | lb.in | ISO 10964 |

| Breakloose Torque (Pre-torque to 5 N․m) (M10 steel nuts and bolts) | 61.0 | lb.in | ISO 10964 |

| Breakloose Torque (Pre-torque to 5 N․m) (M10 Zinc dichromate nuts and bolts ) | 58.0 | lb.in | ISO 10964 |

| Prevail Torque at 180° (Pre-torque to 5 N․m) (M10 steel nuts and bolts) | 11.0 | lb.in | ISO 10964 |

| Prevail Torque at 180° (Pre-torque to 5 N․m) (M10 Zinc dichromate nuts and bolts) | 4.0 | lb.in | ISO 10964 |

| Compressive Shear Strength (Steel pins and collars) (After 30 minutes at 25 °C) | 203.0 | psi | ISO 10123 |

| Compressive Shear Strength (Steel pins and collars) (After 24 hours at 25 °C) | 39.0 | psi | ISO 10123 |

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- Chemical/Solvent Resistance

Aged under conditions indicated and tested @ 25 ℃

% of initial strength Environment Temp. ℃ 100 hrs 500 hrs 1000 hrs 3000 hrs Unleaded Petrol 25 110 100 90 85 Water/ethylene glycol 50/50 87 100 100 100 100 IPA 25 100 100 90 85 Acetone 25 100 95 95 90 - Typical Curing Performance

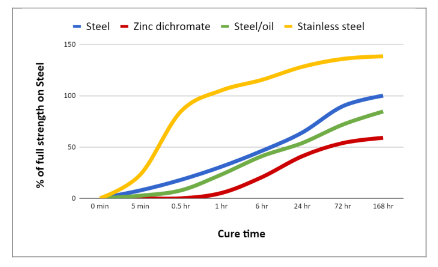

Cure Speed vs. Substrate

The rate of cure will depend on the substrate used. The graph below

shows the breakaway strength developed with time on M10 steel

nuts and bolts compared to different materials and tested according

to ISO 10964.

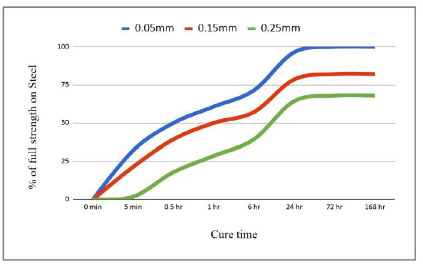

Cure Speed vs. Bond Gap

The rate of cure will depend on the bondline gap. Gaps in threaded

fasteners depends on thread type, quality and size. The following

graph shows shear strength developed with time on steel pins and collars at different controlled gaps and tested according to ISO

10123.

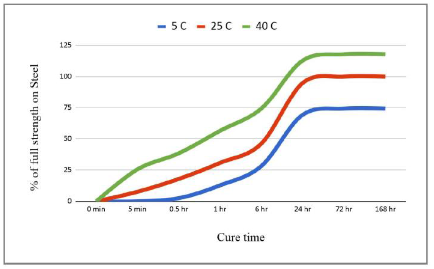

Cure Speed vs. Temperature

The rate of cure will depend on the temperature. The graph below

shows the breakaway strength developed with time at different

temperatures on M10 steel nuts and bolts and tested according to ISO

10964.

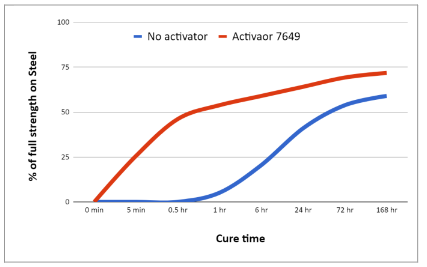

Cure Speed vs. Activator

Where cure speed is unacceptably long, or large gaps are present,

applying activator to the surface will improve cure speed. The graph

below shows the breakaway strength developed with time on M10

zinc dichromate steel nuts and bolts using Activator 7649 and tested

according to ISO 10964.

- Typical Environmental Resistance

Cured for 1 week @ 25 °C

Breakloose Torque, ISO 10964, Pre-torque to 5 N.m

M10 steel nuts and bolts

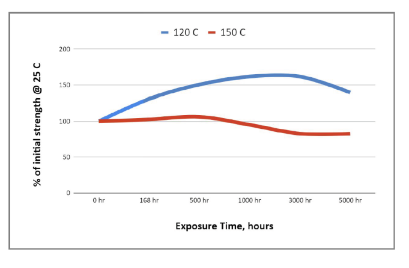

Heat Aging

Aged at temperature indicated and tested @ 25 °C

Safety & Health

- Precautions

1. Avoid contact with skin and eyes.

2. If contact with skin, rinse with water.

3. If adhesive gets into eye, keep eye open and rinse with water thoroughly. Seek medical attention immediately.

4. Keep the material out of children’s reach.

Storage & Handling

- Shelf Life

- 24 months unopened when stored at 8 to 24 °C

- Storage

Keep adhesive in a cool and dry place. The storage temperature is recommended at 8 °C to 24 °C. Shelf life is two years from the date of manufacture in the original container under the optimal conditions.< /p>